Home › Forum › Ask A Member › Johnson Dt-10 Gearcase removal question.

- This topic has 8 replies, 2 voices, and was last updated 4 years, 7 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

June 7, 2021 at 5:46 pm #239665

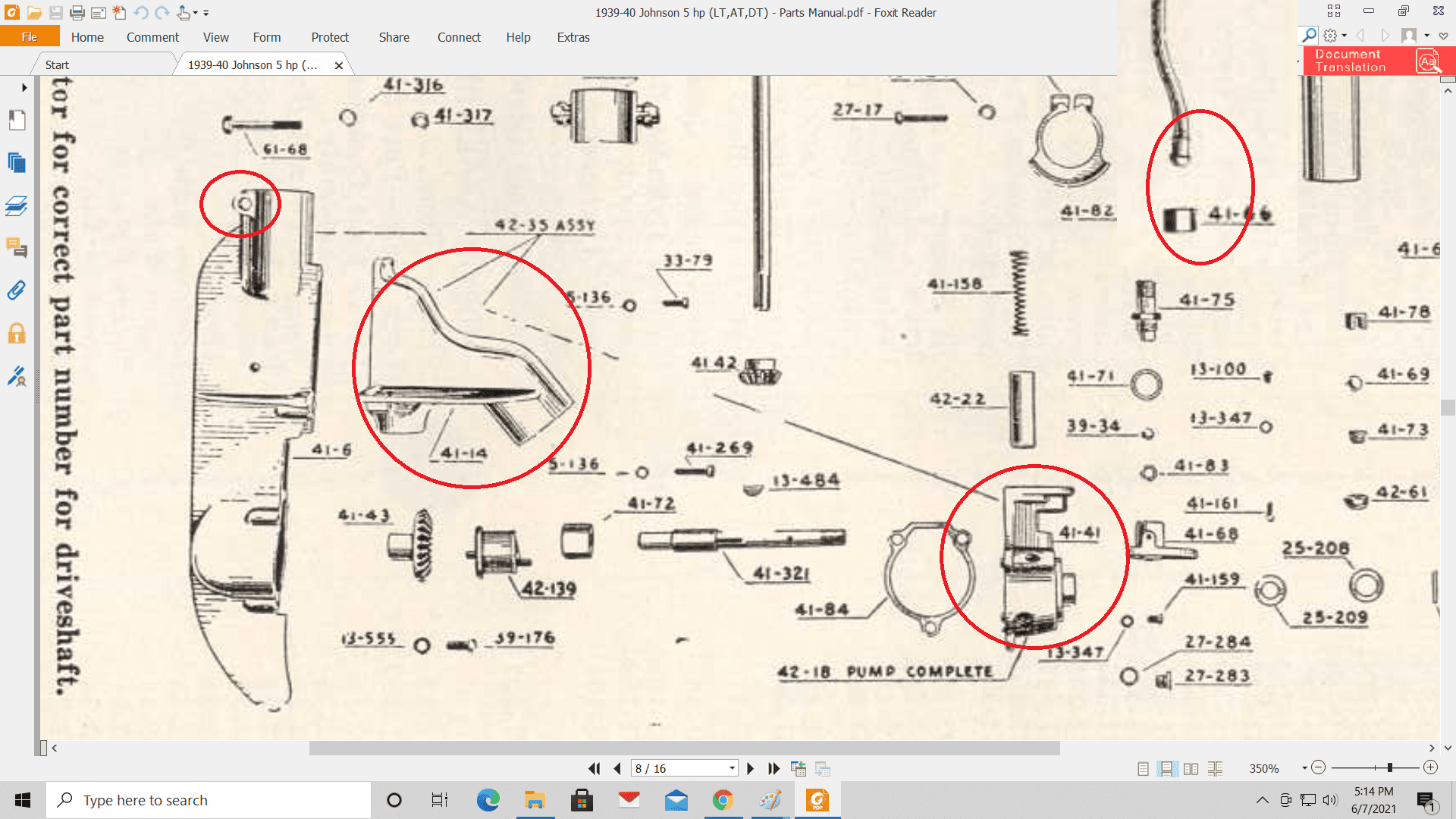

I have a replacement gearcase and driveshaft for my DT-10. Do I have to pull the inner driveshaft casing and water tube, or should the gearcase come loose after loosening the clamp bolt? Manual is unclear (to me) if the tubes need removed to get the gearcase loose. Calls for special tools S-260 and S-261. I loosened the bolt, tried wiggling with large channel locks, no movement, I don’t want to force anything and cause more problems. Thank you

-

This topic was modified 4 years, 7 months ago by

wanderlustjake.

June 7, 2021 at 6:22 pm #239667It’s been quite a while since I worked on mine, but from what I remember, and from

looking at the parts diagram……

-Remove the exhaust snout, gear case prop shaft cap, unhook the water line from the pump, and remove the water pump assembly,

and remove the “through bolt” holding the gear case to the drive shaft tube.

Tap the gear case down and off the driveshaft tube with a block of wood and hammer.

It seems like it’s a little tricky not to bend the water discharge tube, so be careful.

Other’s may have better advice, or memory!Prepare to be boarded!

June 7, 2021 at 6:44 pm #239676Thank you again Buccaneer. I wanted to ask, double check that I’d don’t miss something. That water line looks like it will be tricky. It’s soaking with wd-40 now. Hopefully bthat and a heat gun will help.

June 12, 2021 at 4:35 pm #240089Making progress. I discovered that by grinding the points of a 1″ spade bit, it fit perfectly to remove the nut holding the driveshaft casing. Once that was done and I scraped away some of the carbon and gunk, I was able to push the casing tube down and tap the gearcase free without damaging the water line. While tapping it free, the pin that holds the pinion gear at the correct height appeared.

Pretty happy now.June 12, 2021 at 6:53 pm #240093Sounds like good progress, keep up the good work!

Prepare to be boarded!

June 12, 2021 at 7:49 pm #240098Do you know if there is supposed to be sealant at the driveshaft casing tube and top but joint? When I pulled mine apart I noticed a red sealant on the tube…

June 12, 2021 at 8:41 pm #240099It certainly wouldn’t hurt to put some kind of sealant on the tube, if for no other reason

to keep corrosion out of the joint so it will come apart easier next time.Prepare to be boarded!

June 12, 2021 at 9:59 pm #240101I am now wondering if I should seal it or put some never seize on it since it was on the threads too. I wonder if that’s what they were trying to accomplish?

June 13, 2021 at 8:46 am #240114I use the Indian Head Shellac type sealer on a lot of threads. I guess anti-seize

will react if used on the wrong metals, causing seizing, but perhaps is takes

100 years…….. have no idea!Prepare to be boarded!

-

This topic was modified 4 years, 7 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.