Home › Forum › Ask A Member › Johnson HD-25 Drive Shaft Seal

- This topic has 5 replies, 3 voices, and was last updated 3 years ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

February 25, 2017 at 2:21 am #6417

Has anyone attempted to replace the drive shaft seal

on a Johnson HD-25.

Besides being a tiny seal, down in a 4" deep hole, the 300687 upper seal

appears to be NLA.

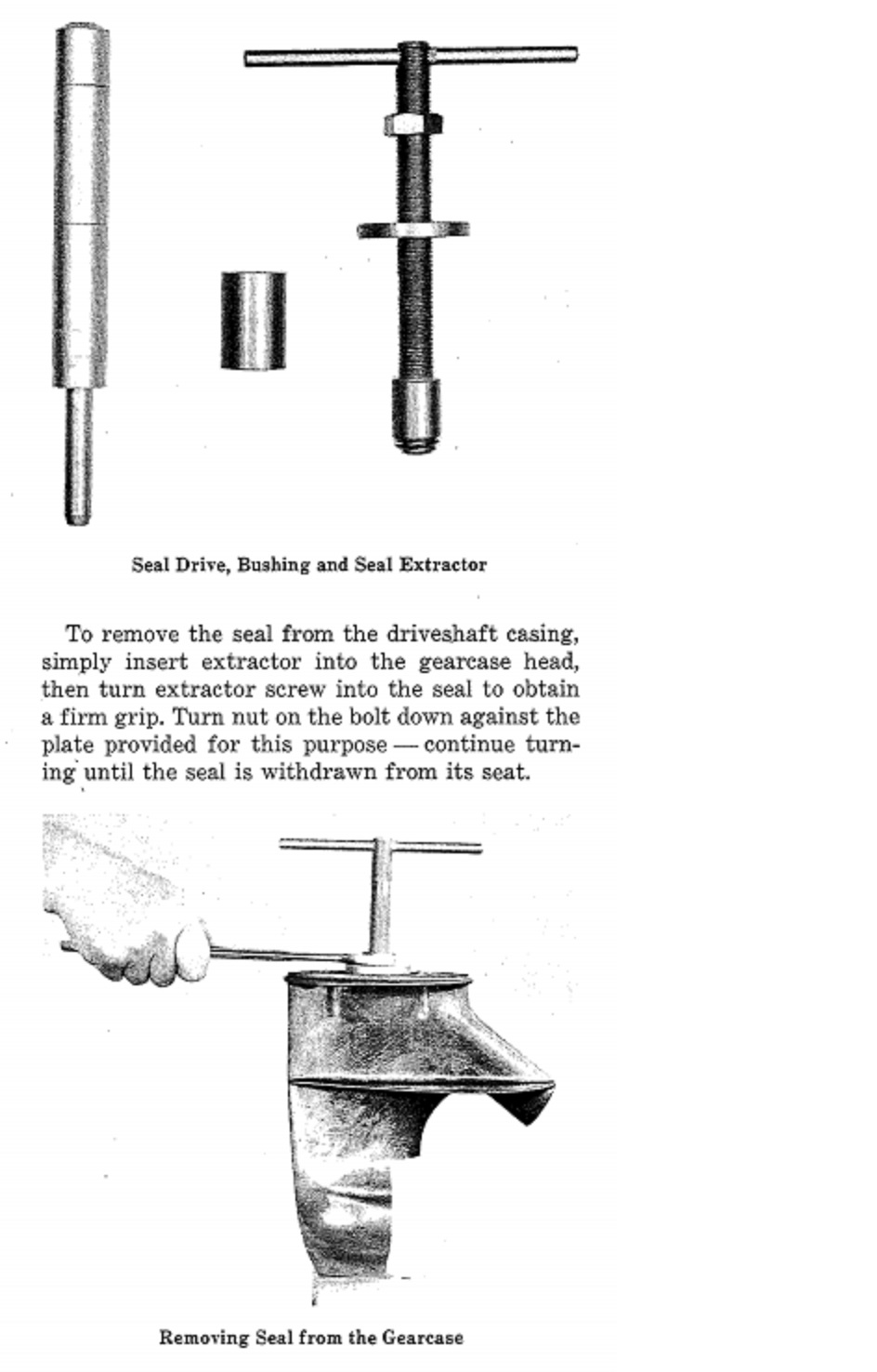

The Johnson manual shows using an extractor as in the photo.

I hate to rip it to shreds getting it out if I can’t find one anyway.

As is, I can’t get light down the hole good enough to even

see if the old seal is in one piece.

Thoughts?

Update – Even though the manual has the Lower Unit procedures

lumped together for the HD and TD model Johnsons, I believe

the seal extractor and bushing driver are only for the TD models.

The manual says the bushings in the lower unit (presume they’re talking

about the HD model) are "cast" in the housings and not removable,

hence if worn the housings, they must be replaced.

I looked with a better light today, and see nothing that looks like

a normal drive shaft seal. If there is one down in that hole, it’s

a long (perhaps fiber) affair that sits on top of the drive shaft

bushing.

I will leave well enough alone, but am still curious if anyone knows

what kind of drive shaft seal the HD has, if any.

The drive shaft is sealed in a housing all the way to the power head,

so there should be no water intrusion above the drive shaft bushing anyway!Prepare to be boarded!

February 26, 2017 at 12:04 am #53560Hey Buc, I’m not fortunate enough to own that special tool, but I’d like to check one out! There is a replacement seal out there for your driveshaft. You need to find out the spec’s for the seal and search from there.

Removing seals is my least favorite task. I have had limited success with a slide hammer, but also had ones that had to be basically collapsed inward and taken out in small pieces.

There was a recent thread where Mumbles showed a picture of a seal that was drilled into, and wood screws were threaded into the top of the seal on opposite sides. The tops of the wood screws could then be latched onto to help pull out the seal. I haven’t tried that method yet, but it is worth a try.

Improvise-Adapt-Overcome

February 26, 2017 at 1:59 am #53564Aquasonic, I need to come up with a way to actually see down

into the hole where the seal goes. My trouble light is nothing

but trouble! I have done the wood screw and lag bolt method

of seal removal on cars, trucks, tractors, etc., but to remove

a tiny seal down inside of a 4" hole, the OMC type tool

would be great!

Not sure if an "auger" style thread could be done on a lathe

or not if one was inclined to make such a tool.

What do you machinist think about that?

Thanks!Prepare to be boarded!

January 16, 2023 at 2:46 pm #271246A little bit late to the discussion, but I just rebuilt a lower on an MS-20, but the parts are the same. Mine had no seal in it and as you can imagine, the engine was a mess with extra lube getting out.

I made a tapered brass gauge that I was able to get to the seal area to get a ring on and then measure. Mine has a seal bore diameter of .555″ diameter. I wound up giving it a quick hit with a 9/16″ hand reamer and with that, CR lip seals 3621 pressed in with a nice snug fit. Easy work to get around an NLA part……

The interesting thing is that I could see no evidence of my engine every having been apart. Could that seal have just been missed during original assembly? No messed up screw heads, no torn gaskets… Hard to say since it is 80 years old but it makes you wonder.

January 16, 2023 at 2:46 pm #271247A little bit late to the discussion, but I just rebuilt a lower on an MS-20, but the parts are the same. Mine had no seal in it and as you can imagine, the engine was a mess with extra lube getting out.

I made a tapered brass gauge that I was able to get to the seal area to get a ring on and then measure. Mine has a seal bore diameter of .555″ diameter. I wound up giving it a quick hit with a 9/16″ hand reamer and with that, CR lip seals 3621 pressed in with a nice snug fit. Easy work to get around an NLA part……

The interesting thing is that I could see no evidence of my engine every having been apart. Could that seal have just been missed during original assembly? No messed up screw heads, no torn gaskets… Hard to say since it is 80 years old but it makes you wonder.

January 16, 2023 at 5:26 pm #271259A little bit late to the discussion, but I just rebuilt a lower on an MS-20, but the parts are the same. Mine had no seal in it and as you can imagine, the engine was a mess with extra lube getting out.

I made a tapered brass gauge that I was able to get to the seal area to get a ring on and then measure. Mine has a seal bore diameter of .555″ diameter. I wound up giving it a quick hit with a 9/16″ hand reamer and with that, CR lip seals 3621 pressed in with a nice snug fit. Easy work to get around an NLA part……

The interesting thing is that I could see no evidence of my engine every having been apart. Could that seal have just been missed during original assembly? No messed up screw heads, no torn gaskets… Hard to say since it is 80 years old but it makes you wonder.

Nice “work -around”!

Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.