Home › Forum › Ask A Member › Johnson HD-25 running issues

- This topic has 12 replies, 5 voices, and was last updated 8 years, 9 months ago by

aquasonic.

-

AuthorPosts

-

April 20, 2017 at 12:52 pm #6796

I’ve gone thru three HD-25’s.

#1 was my best hope of a good running 2-1/2 hp Johnson,

as it has 77 psi compression top and bottom.

The other two have 65 ish compression, and just don’t

want to idle.

I’ve had the mag apart four times in the last couple of days.

First time I did have poor spark as I had the fiber washers

placed wrong on the "kill post".

At one point, the little outboard ran down in the slow range

nicely for a minute or so, but started running erratic.

I’ve tried the coil heel to magnetic rotor set at .008

and .012 as the manual says. I think spark jumping an

air gap was better at .008.

I had adjusted the points at .020 and called it good,

but yesterday I put at dial indicator in the plug holes

and hooked up a buzz box across the points to get

the two cylinders synced in their firing as close as I could.

It runs nice "Fast", but when you get down to the "Start"

area, it bogs out.

I’ve tried all combinations of setting the "Low" and "High"

speed needles. So far the best combination seems to

be about 1/2 turn open on each needle. I tried starting

out at the manual’s recommended 3/4 turn each, but

it ran way too rich.

This is the only one of the three HD’s that I replaced the

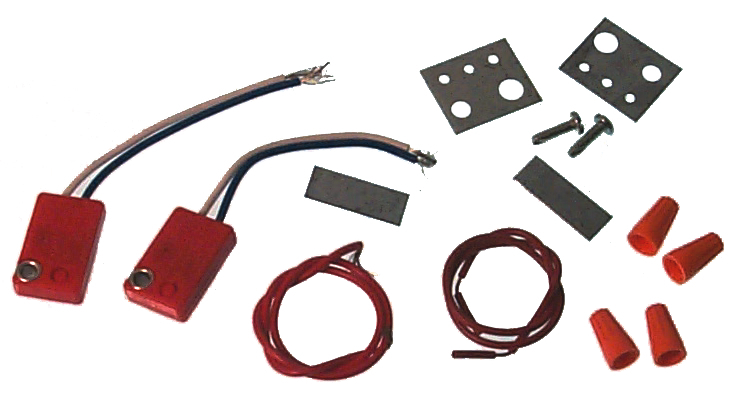

condensers with .20 uf "orange cap" capacitors.

All the carbs were "cleaned, probed, and blown out", etc.,

so I’m not sure what the problem could be.

The flywheel had no noticeable sideways movement.

I have an older HD-15 apart but not real hopeful

it will run any better!

Running out of my own ideas.

Suggestions welcomed. Thanks!Prepare to be boarded!

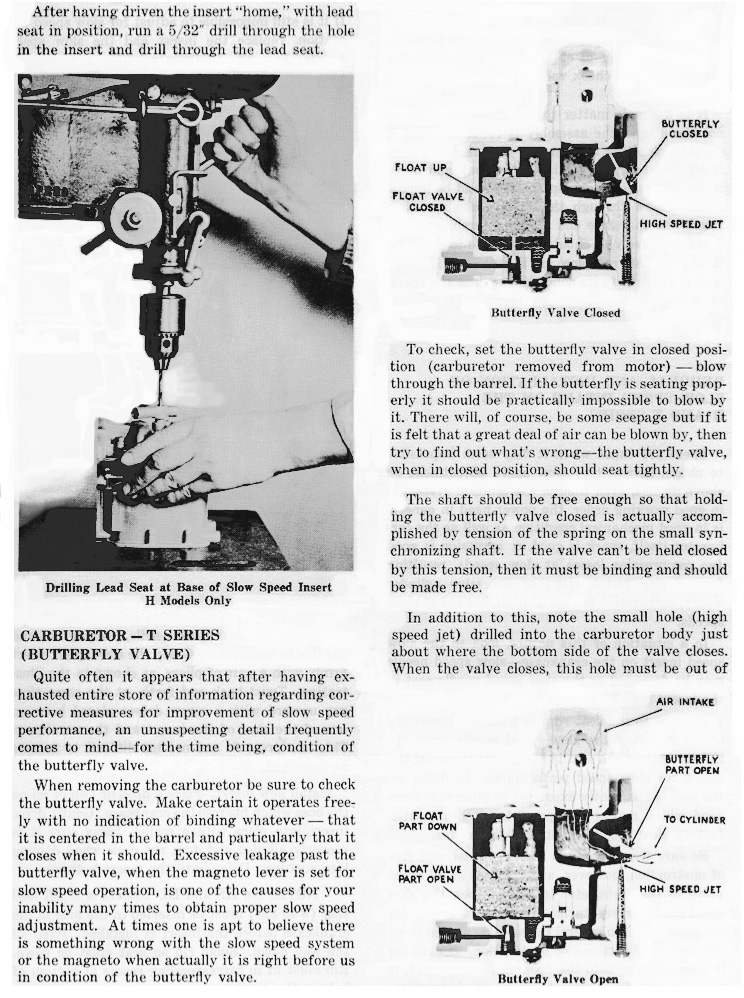

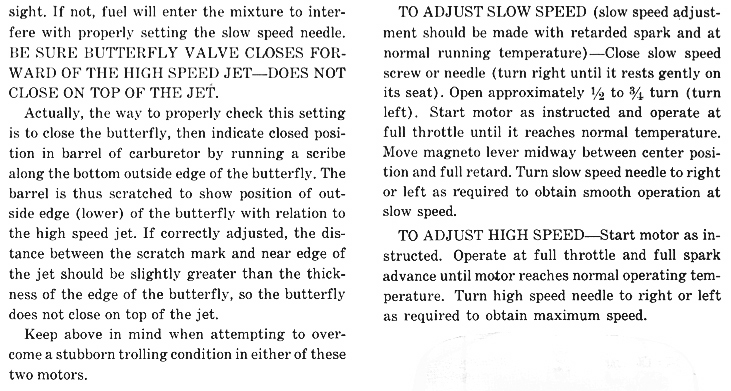

April 20, 2017 at 2:19 pm #56416This is what I have . . . 🙄

April 20, 2017 at 3:39 pm #56422

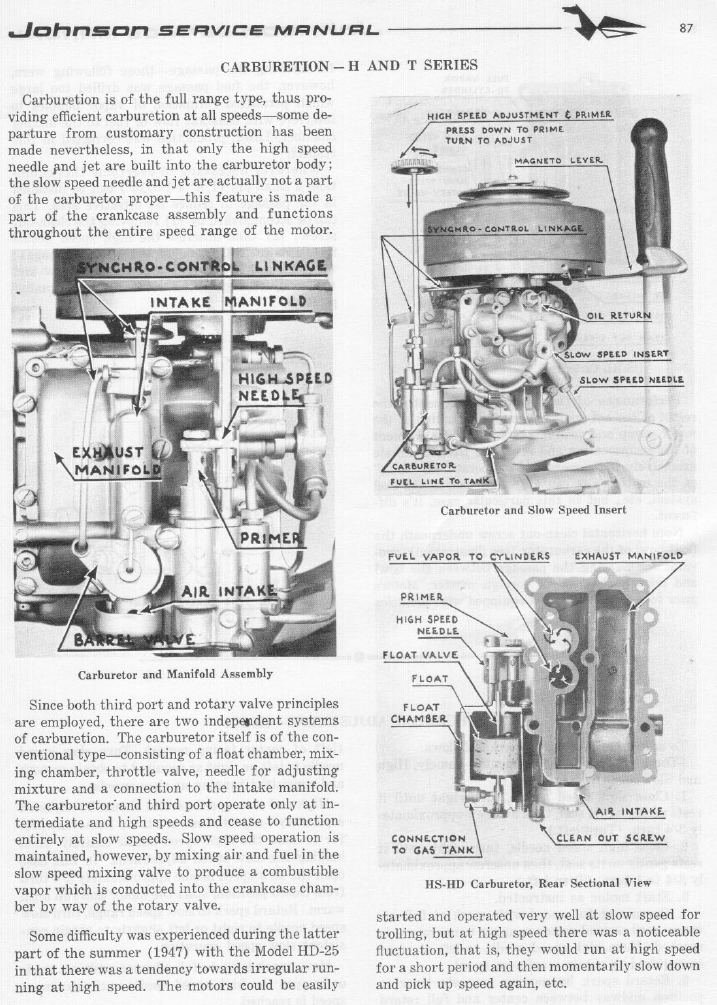

April 20, 2017 at 3:39 pm #56422Garry, Thanks. I have the same information, some probably

from you last year :-), but it’s making me think more

about the carburetor itself.

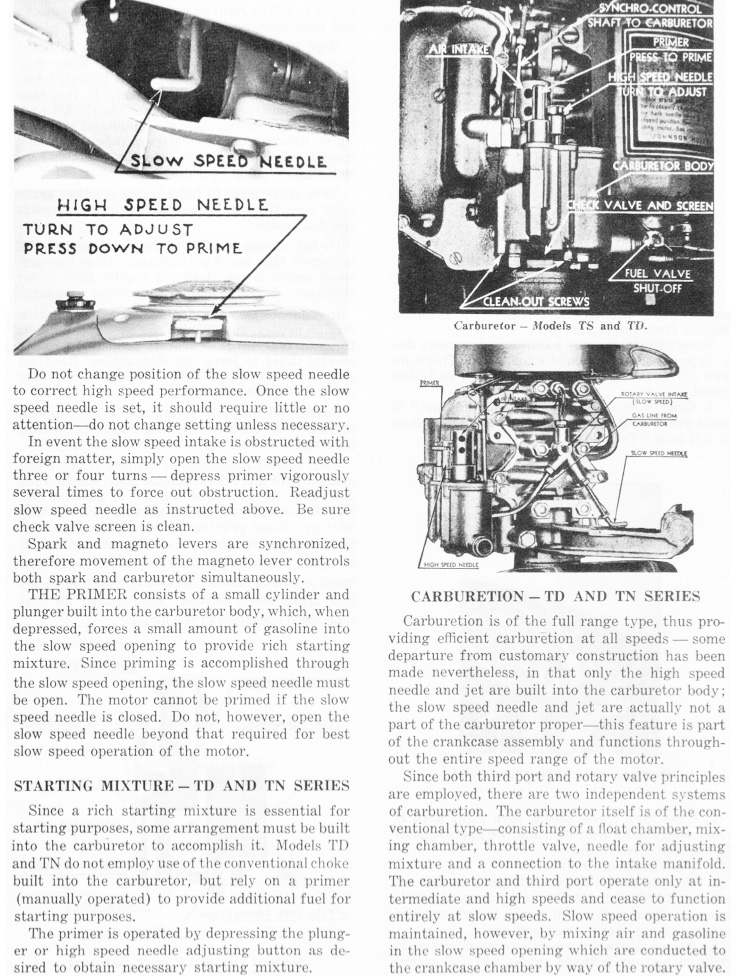

I don’t think the syncro linkage from the mag to carb

is adjustable (other than bending it), but something

to think about. Will read the carb data again!

Thanks!Prepare to be boarded!

April 20, 2017 at 7:48 pm #56431Usually if the primer works and the taper on the idle needle valve is even, the idle should be good. If the hole in the crankcase is plugged behind the low speed insert, that’s another story. . . 😕

April 20, 2017 at 10:06 pm #56439

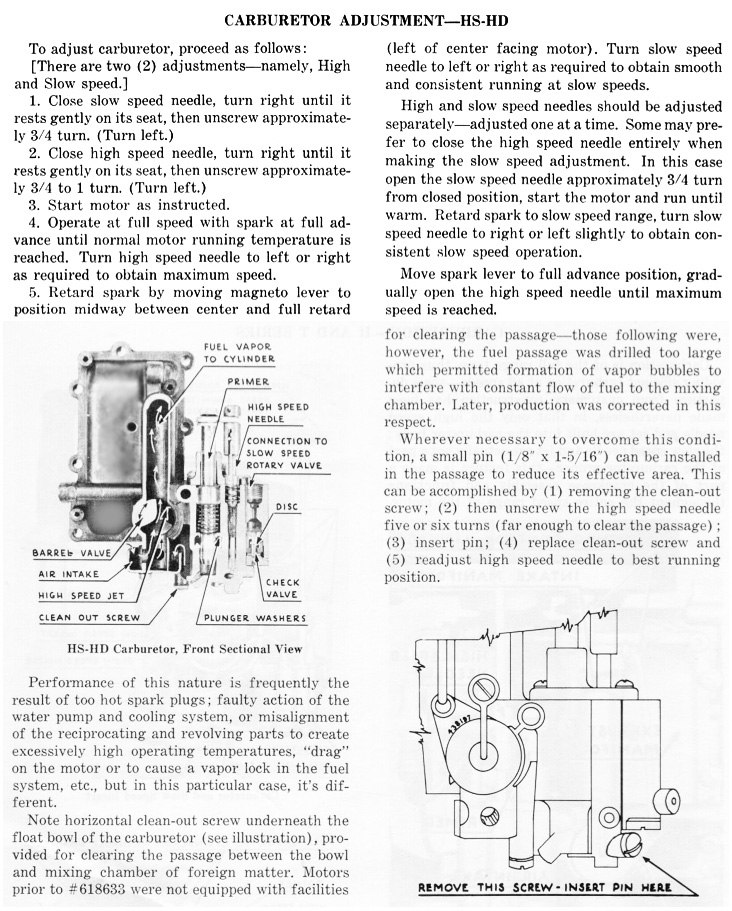

April 20, 2017 at 10:06 pm #56439Garry, after re-reading the "HD & HS Carb Adjustments"

page you sent, it mentioned an alternate way,

closing the high speed needle all the way, and starting

the outboard with the low speed 3/4 turn open.

Warm it up, tune in the low speed, then go to full

advance and tune in the High speed. I’ve always done

it the "other way" on every other outboard, but

this alternate way worked great on this HD-25.

As I was retarding the magneto, I caught on to

a secondary problem. When retarding to about "Start"

(from the Fast position) it would start running erratic.

The mag lever was vibrating some on the gas tank.

I pushed down on the lever to stop it from rattling,

and it started running normal. Couldn’t see anything

arcing, so I tightened the tension screw tighter

on the mag plate. I had to tighten it so it was a little

stiffer than I’d like, but it took care of the erratic

running, and then idled down smooth as a Swiss watch!

I think I finally have at least one good running HD-25!

Thanks for the help!Prepare to be boarded!

April 20, 2017 at 11:11 pm #56446Glad to hear you got the little guy to finally cooperate! Great news. I have always done it the ‘other way’ too. If I get into one of these, I’ll remember that.

-BenOldJohnnyRude on YouTube

April 21, 2017 at 1:59 am #56454I at least want to get it on the lake once to try it out,

and perhaps even find some little lakes I’ve never been

on to "fish". It would be a great little puddle jumper!Prepare to be boarded!

April 21, 2017 at 5:29 am #56461April 21, 2017 at 12:32 pm #56467Mumbles, that’s food for thought with the modules….

but if an EMP goes off over the lake, will I have to

row home? 🙂

I was wondering if there’s a conductive lubricant

that enhances conductivity that could be used

on mag plates? Some kind of graphite spray?

I’m a little confused about dielectric grease as

it says’ "non conductive", but I’ve used it

on flash light battery contacts to keep them

corroding, and the light still comes on!Prepare to be boarded!

April 21, 2017 at 12:54 pm #56469I believe the idea behind dielectric grease is to keep contaminants including water out and reduce corrosion. Also, by being non-conductive, it helps prevent current leakage around the contact points thereby keeping more of the current flowing in the desired direction rather than escaping through points of potential resistance along the way. I use it a lot and it works well.

-BenOldJohnnyRude on YouTube

-

AuthorPosts

- You must be logged in to reply to this topic.