Home › Forum › Ask A Member › Johnson HD20 Drive Shaft Question

- This topic has 12 replies, 5 voices, and was last updated 10 years, 4 months ago by

kevinf.

-

AuthorPosts

-

October 18, 2015 at 11:17 am #2794

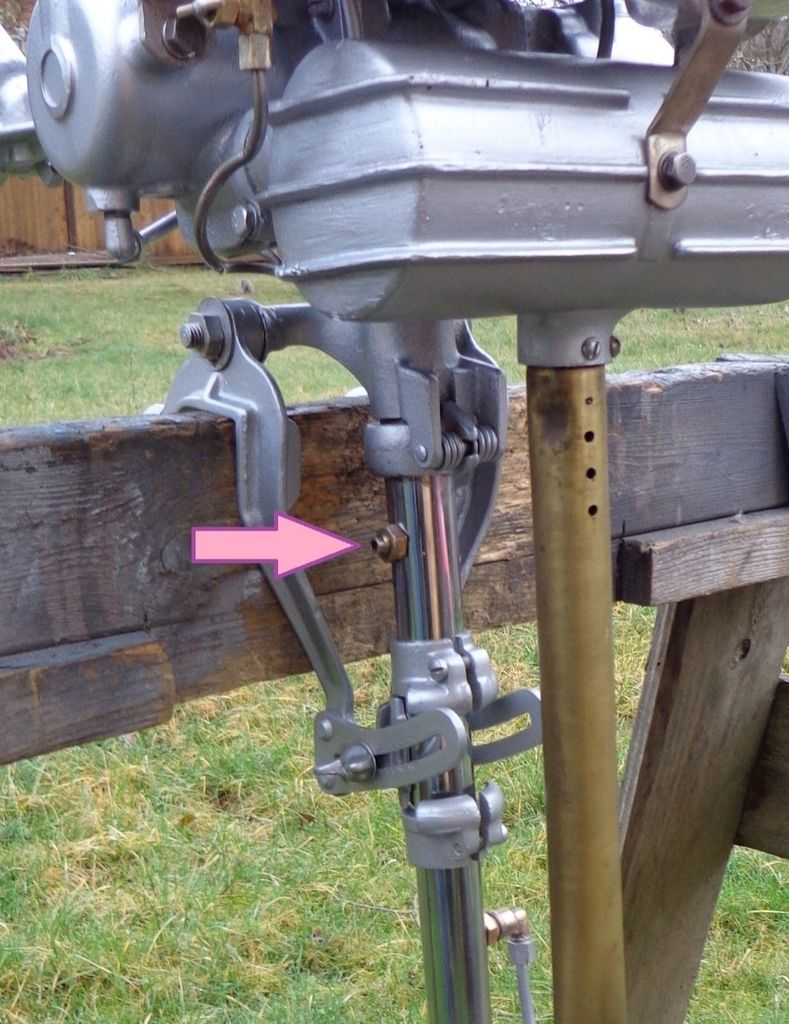

I put my HD-20 away for the winter, will pick up on the low speed running issue in the spring, but I was curious if the drive shaft in these needs to be greased or anything, looked like mine was when I removed it. I was also curious what the small access hole to the drive shaft tube is, I was assuming to grease it. I imagine this feeds right down into the lower unit though.

My next question if filling the lower unit, I just used some 90wt that I had laying around for running in the bucket, but what is recommended and what is the proper fill procedure on these? The only screw I noticed was the large one at the bottom.

October 20, 2015 at 1:02 am #25776I’m no expert by any stretch but I have a a couple of pre-war H series Johnsons and I’m open to correction. I’ve never greased a driveshaft. I wouldn’t want grease blocking any drain holes in the lower unit and trapping water where it can freeze and damage castings. I didn’t check a manual but based on age and the grease plug fitting (NPT threads and no washer) I assumed they were a grease filled lower unit and filled my HD with Cornhead grease.

Kev

October 20, 2015 at 6:51 pm #25807I always apply grease to the entire driveshaft. The top end gets a little extra for the splined connection to the bottom of the crankshaft. The bottom end is important to grease to minimize friction where it passes through the upper gearcase seal. The rest of the driveshaft gets greased for corrosion protection.

I believe the small access hole in the driveshaft tube is the driveshaft tube vent, not a grease/oil fill. If I recall correctly, it looks like a brass hex nut with a hole in the middle on the outside of the motor on the Port side of the mid section. I own a couple of the HD-25’s, and they take 90WT. I’m not 100% sure about the HD-20, but if it doesn’t leak with the 90WT, then your probably OK.

If you look closely at your gearcase, there should be two screws/openings for hypoid oil. Both the fill and the vent are on the Port side with the small vent screw actually above the gearcase in the mid-section. Filling is done through the bottom hole and the top hole is a vent to let air out so the oil can displace it. The idea is to avoid trapped air pockets while filling.

Improvise-Adapt-Overcome

October 20, 2015 at 11:29 pm #25820This has the makings of an interesting question. I was curious so I went out and had a look at a couple of HD-20s in the garage. I have one that’s pre-war. The bottom filler is definitely a grease plug and a grease fitting will screw into place while the vent is higher up on the leg and has a smaller slotted screw. A green postwar HD was similar. Then in the clean out pile I found a gear case and lower leg from an indeterminate HD 20 or 25. The two lubricant screws were more modern with shoulders, coarse threads and gaskets. The top hole was clearly marked for hypoid. I’m with aquasonic in that if it doesn’t leak out you’re probably ok 🙂

BTW I’m convinced that those things multiply in the dark.

October 24, 2015 at 2:08 pm #25972quote aquasonic:

I believe the small access hole in the driveshaft tube is the driveshaft tube vent, not a grease/oil fill. If I recall correctly, it looks like a brass hex nut with a hole in the middle on the outside of the motor on the Port side of the mid section. I own a couple of the HD-25’s, and they take 90WT. I’m not 100% sure about the HD-20, but if it doesn’t leak with the 90WT, then your probably OK.

Is this what you are referring to? I have a similar 1940 HA-15 with the same setup. I haven’t been able to get a clear answer on what the purpose of the nut with a hole in it is for?

The 2 small holes are the coolant water spray holes.

October 28, 2015 at 2:08 am #26168@ MarvK. My HS-10 is at the cottage so I couldn’t check it but I went out to the scrap heap and pulled out an HD-20 or 25 lower unit. That bolt holds the inner drive shaft casing in place. The hole goes through the inner casing. It may have had a role in the assembly process but it appears to vent/drain the inner casing. The other two holes go into the outer casing. From the parts manuals the two motors (HD and HS) seem to have a similar construction with inner casing the driveshaft runs in. That help any?

KevOctober 28, 2015 at 12:11 pm #26185quote MarvK:quote aquasonic:

I believe the small access hole in the driveshaft tube is the driveshaft tube vent, not a grease/oil fill. If I recall correctly, it looks like a brass hex nut with a hole in the middle on the outside of the motor on the Port side of the mid section. I own a couple of the HD-25’s, and they take 90WT. I’m not 100% sure about the HD-20, but if it doesn’t leak with the 90WT, then your probably OK.

By the looks of MarvK’s second picture that driveshaft tube needs some venting. I have an HD-25 that has the same situation with that nasty looking spooge leaking out of the same vent. Some time ago, someone posted a picture with that similar situation and they attributed it to a loose gasket. The specific gasket was not mentioned though.

Improvise-Adapt-Overcome

October 28, 2015 at 11:16 pm #26211The inner casing goes up into the lower flange and tube assembly. There’s a gasket between that assembly and the block with a passage through it. I’m not 100% sure but it looks to me like that’s the outlet for the cooling passages in the block. Seepage there with a bit of oil coming from the bottom of the crankcase would make a nice ooze.

Kev

October 30, 2015 at 11:56 pm #26290quote kevinf:The inner casing goes up into the lower flange and tube assembly. There’s a gasket between that assembly and the block with a passage through it. I’m not 100% sure but it looks to me like that’s the outlet for the cooling passages in the block. Seepage there with a bit of oil coming from the bottom of the crankcase would make a nice ooze.

KevThanks Kevin,

That makes more sense now, thanks for the explanation. If nothing else, it does keep the swivel bracket lubricated. 😆

October 31, 2015 at 12:59 am #26297Wouldn’t the two holes be the idle relief openings while the fitting with the nut would be the water outlet like on this Johnson?

-

AuthorPosts

- You must be logged in to reply to this topic.