Home › Forum › Ask A Member › Johnson K50 Lower Unit

- This topic has 10 replies, 5 voices, and was last updated 8 years, 11 months ago by

hotrod.

-

AuthorPosts

-

February 5, 2017 at 3:02 am #6269

Anonymous

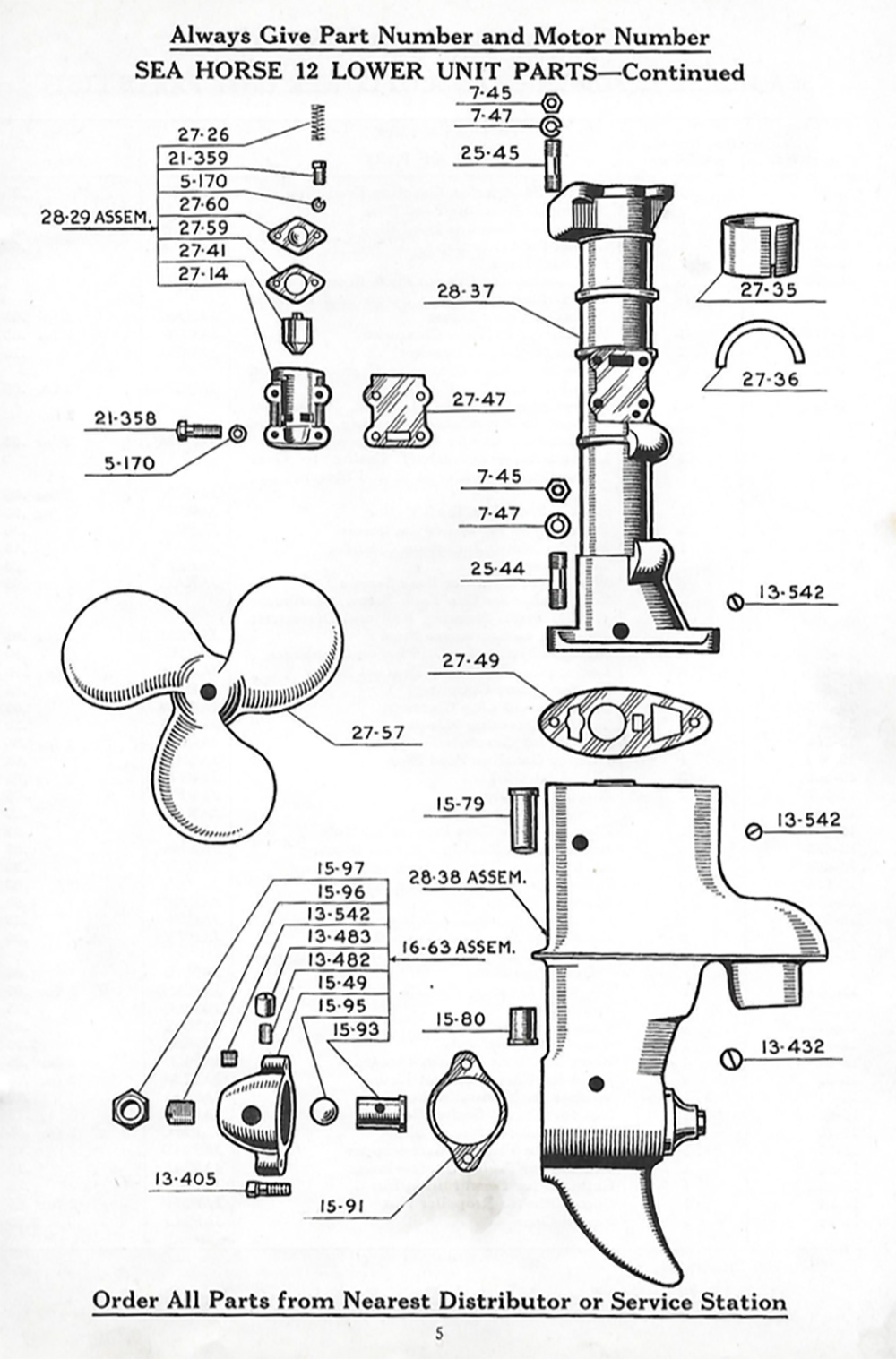

Hey There! Does anyone have an exploded view of the Johnson K50 (or comparable) lower unit? Seems like I’ve looked everywhere a person can look. I have the X-section, but could really use an exploded view…..My mind works kind of like that, if at all! Thanks!

February 5, 2017 at 3:55 am #52412Here it is if I figured this right

February 5, 2017 at 3:56 am #52413February 5, 2017 at 4:02 am #52414Let me know if this works, I could not get it to post and be seen

February 5, 2017 at 5:03 am #52418February 5, 2017 at 2:11 pm #52428Anonymous

Many thanks!! I’ll see if I can get that thing apart without parts flying everywhere. Seems like I read in an AOMCI post that there is a spring involved in there somewhere.

February 5, 2017 at 7:56 pm #52455You should wait until someone posts the exploded view of the propshaft. IIRC, there is a spring clutch in there. The brass ring that compresses the spring is often cracked or broken from over torquing.

Tom

February 6, 2017 at 1:26 am #52486Anonymous

Thanks Tom. You’re correct, the nut was broken straight across the bottom. The spring was broken in the middle. Looks to have been broken for years before the motor was retired. As I posted later, a machinist/welder seems to think the nut is broken so cleanly and evenly it can be repaired. I’m looking for the method of proper tightening and securing it. Thanks for your reply.

February 6, 2017 at 1:53 am #52487I’ve heard that the cones can be pinned together, and the spring left out. Then a brass pin used at the prop in case it hits something.

Tom

February 6, 2017 at 2:27 am #52488Anonymous

I’ll have to go back and take a look tomorrow to understand the "cones". There’s a brass pin in the prop shaft at this point. I’m trying to get an idea how tight that bronze nut needs to be. Also, there’s that screw and lock nut in the back that moves the rear shaft bushing. That bushing was wedged solid….no adjusting that, so I finally drove it out, emeried it up and it moves like it’s supposed to. I guess that adjusts the ball bearing clearance. I really appreciate your time.

-

AuthorPosts

- You must be logged in to reply to this topic.