Home › Forum › Ask A Member › Johnson LT 37

- This topic has 11 replies, 4 voices, and was last updated 2 years, 6 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

July 9, 2023 at 12:48 pm #277909

Hi Guys.

Going to need some help with this one. Gifted to me is a Johnson LT 37. I have done some clean up and inspecting. So far it’s missing a driveshaft, needs new piston rings and I believe the coil is not working. I cleaned the carb, made a new float but I’m not sure if it uses leather seals like the TN or TD’s do. I tried to remove the brass cylinder with the tap method. No go.(to expose the seals). I will start with a few pics and go from there.

July 9, 2023 at 2:07 pm #277913It uses leather seals like the TD and others. Use a 1/2-13 tap to remove the brass cylinder . Pour some liquid wrench into the cylinder and warm the carb with a hair dryer. Screw in the Tap just enough to get a good grip. If the cylinder turns just pull it out as you turn it. If not, apply vise grips to the tap and tap LIGHTLY and repeatedly up with a small hammer.

July 9, 2023 at 3:16 pm #277914

I had a carb. corroded like yours and I broke

the casting trying to get the sleeve out.

Never did. You may have better luck than me.

Those coils are not usually bad but everything

in that magneto need to be set just so for it

to work. There people that post here that

understand them. I’m not one of them.

Tubs.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

July 14, 2023 at 4:46 pm #278046How do I test this?

July 14, 2023 at 6:11 pm #278050How do I test this?

Test with an ohm meter across the two plug wire terminals at the

coil (secondary). Not sure of the exact reading to expect on this

coil, but think between 4k to 8k ohms.To test the primary windings, connect the ohm meter to the small wire

that goes to the points, and the other small ground wire. Usually

the primary will only be one or two ohms.Prepare to be boarded!

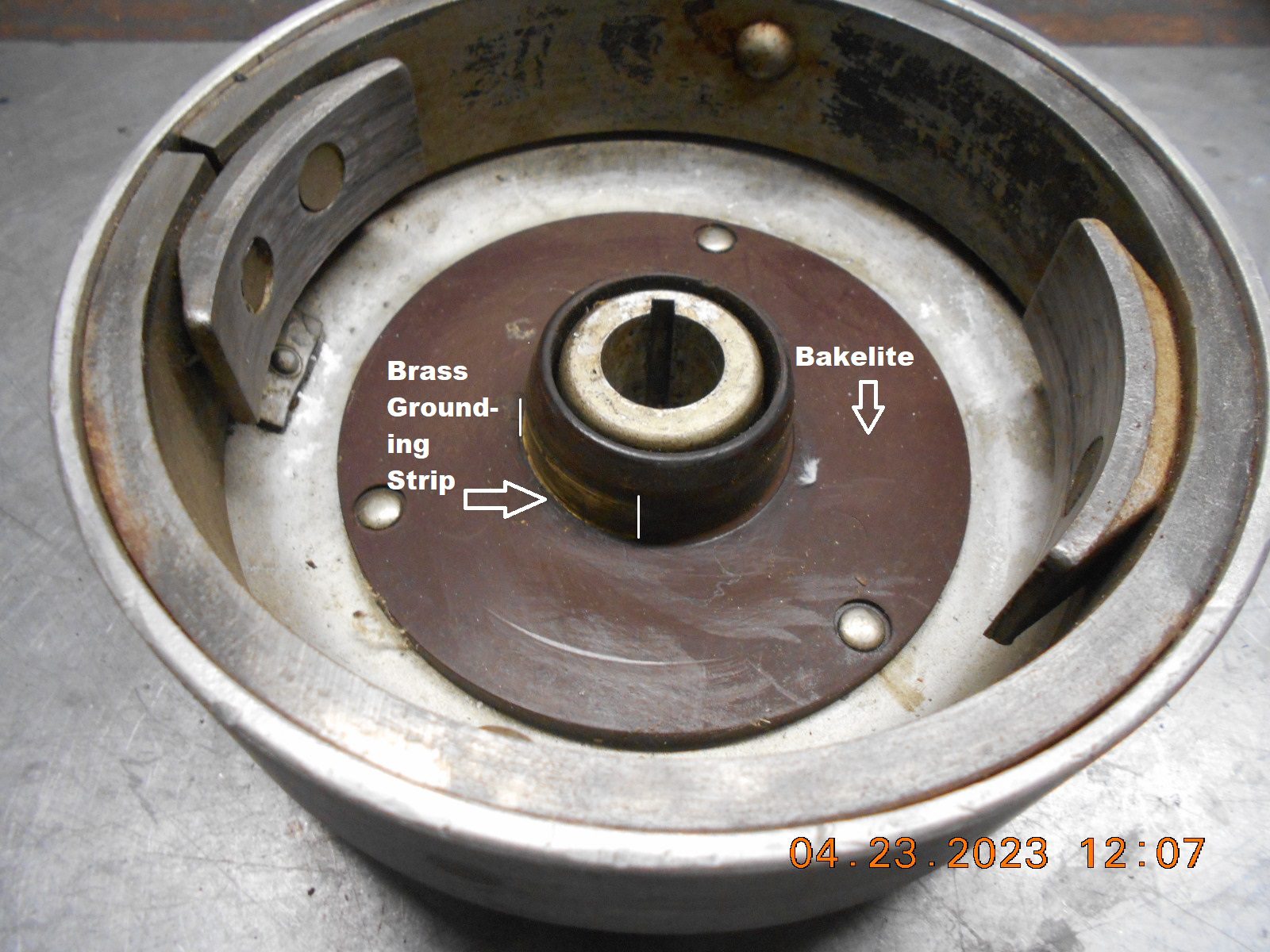

July 14, 2023 at 6:30 pm #278054Just looked in my “Notes” on my LT-37……….

==============================

1937 Johnson LT-37, 4.2 hp

Serial 269570

Complete, minus one transom screw pad.T – 60 psi compression

B – 58 psiCoil, primary .1 ohm, secondary 3.21K ohms

No continuity on the flywheel bakelite distributer

contact, “to ground”.==========================

The last entry in my notes refers to the “grounding”

system that allows the coil only to “fire” the piston at

Top Dead Center.If you have to remove the Bakelite plate, be very cautious,

as it could break easy. Mine already had a crack in it, but

it didn’t effect it’s operation.Prepare to be boarded!

July 14, 2023 at 8:54 pm #278060

In this video Doug shows how to test the

secondary’s in a coil like you have at 8:40.

You will be looking for something close

to the spec. Buck has provided,

https://youtu.be/KT8rk5QWgS0

Tubs.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

July 15, 2023 at 11:54 am #278072Looks like primary good,secondary not. What or where do I find a replacement?

I also need piston rings and a drive shaft?July 15, 2023 at 12:27 pm #278074The 1939 – 40 LT parts manual shows the rings

as part number 41-333.Not sure if your 1937 is the same.

Marine Engine has rings, but very spendy.

If it had okay compression, I’d re-use the old rings, unless they’re broken.

Regarding the coil………. Ebay, or place an ad on this site, or go to Tomahawk!https://www.marineengine.com/newparts/part_search.php?part_num=041333

Prepare to be boarded!

July 15, 2023 at 2:34 pm #278075

If you’re sure you were using the right 1000 ohm

scale, often marked K on a meter, and you’re sure

your coil is bad, the LS & DS models (S is for single)

use the same coil grounding out one side. You can

include them in your search for a replacement coil

Otto Gas Engine Works can also be a source for rings.

Last time I got any they were $5.00 + $.50 shipping

each ring. He doesn’t know anything about old

outboards. You have to provide dimensions.

https://www.ringspacers.com/

Tubs.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.