Home › Forum › Ask A Member › Johnson rd-14 Cowling Screws

- This topic has 6 replies, 4 voices, and was last updated 5 years, 10 months ago by

olcah.

olcah.

-

AuthorPosts

-

April 27, 2020 at 12:33 pm #201203

I recently bought a 53′ RD-14 and two RDE-16’s that I am going to setup twin motors on the back of my aluminum boat. All three motors are missing all but one single screw to hold on the cowlings. I have the parts manuals for this motor but I cannot find these screws anywhere. I know they are simply machine screws so if anyone knows the length and quantity I need I have a hardware store that carries most lengths. Any help is very much appreciated!

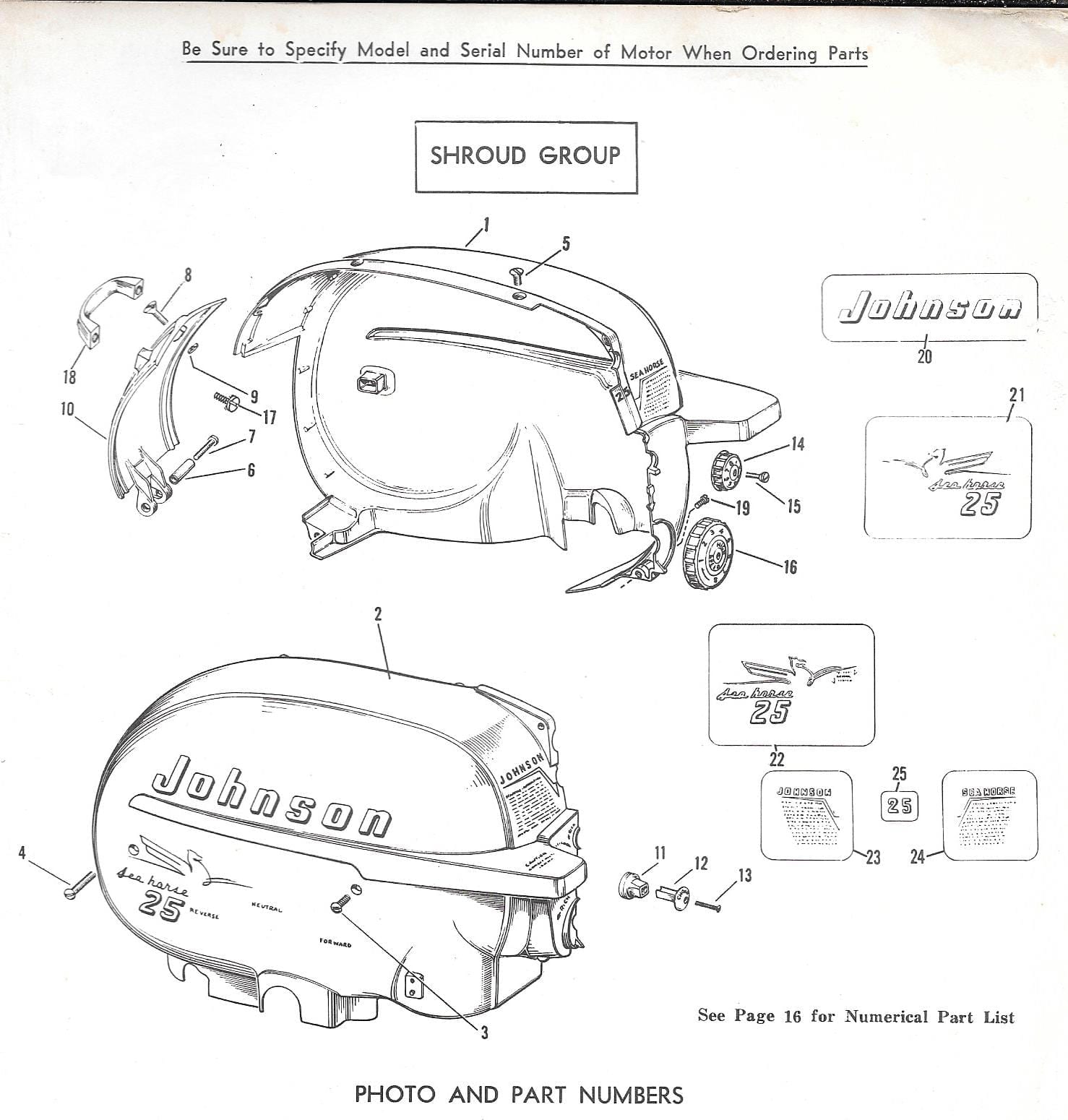

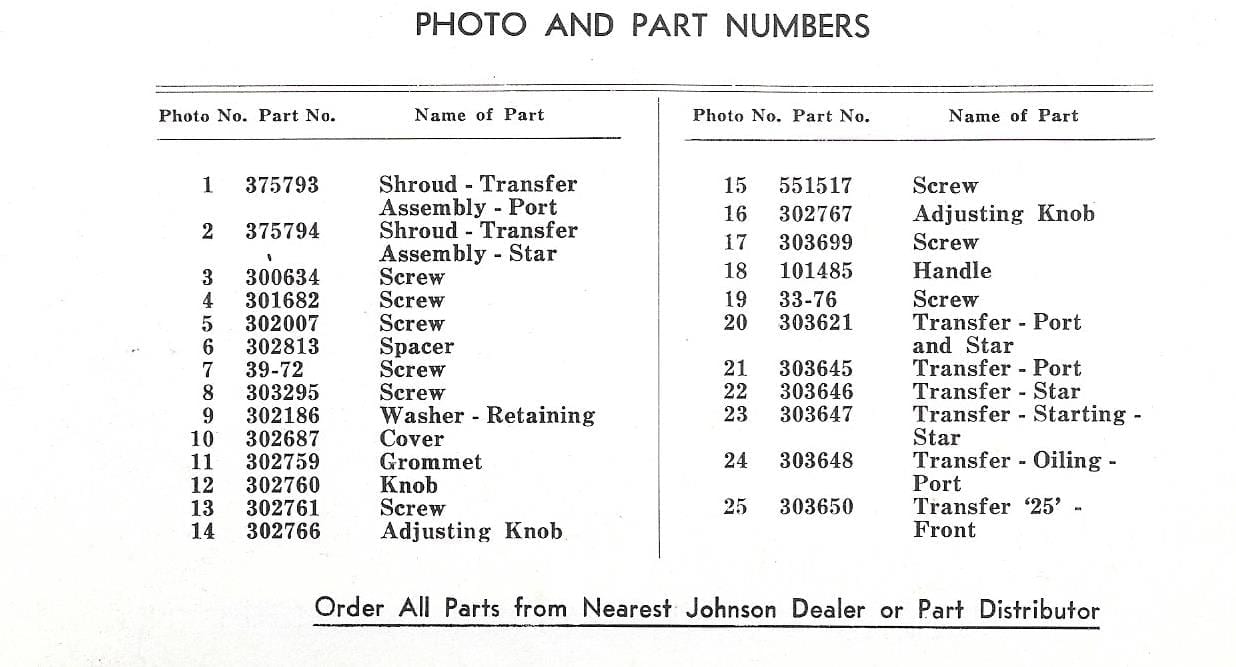

April 27, 2020 at 1:33 pm #201204RD-14 and RD-16 show the same Part #s. I assume you want fig. #3 and #4 so here are the part #s

They are pictured with the cowl

fig#3 300634

fig#4 301682April 27, 2020 at 1:42 pm #201211Aubuchon Hardware here (Maine) has little drawers that contain stainless 1/4-20 screws with heads like these photos that are very near the original appearance. (The originals are plated steel I believe.) I got the 3/4 inch length and shortened a couple with a hacksaw for the cover threads near the manual rewind. If too long they hit the rewind. I’d get about 12 screws to start with. Do not overtighten these as the thread in the cover halves is short and strips easily.

To replace screw number 7 I used a longer 1/4-20 screw, just plain plated. I think I turned down the head diameter to fit the spark plug cover recess. I made the bushing on a lathe from aluminum.

Good luck with your interesting project.

April 27, 2020 at 2:12 pm #201221

April 27, 2020 at 2:12 pm #201221Okay thanks! I figured I would have to get a handful of screws and cut them to length. The only issue I forsee with that is messing up the end threads, is that nothing to worry about or is there a way to clean up the threads after I cut the screws to length?

April 27, 2020 at 3:11 pm #201226put a nut on before cutting then I grind the end then remove the nut,

April 27, 2020 at 3:14 pm #201227After I saw them off I file around the cut end with the file at 45 degrees. Stainless files rather hard but with patience and a good file it can be done. You can also use a grinder, belt sander, or lathe to help. You just want to smooth up the cut end of the thread at about 45 degrees. Get a plain steel 1/4-20 nut to try onto the thread so you don’t force the aluminum threads in the cover. Also if you buy about half of the screws at 1/2 inch long they would be fine. You need the longer 3/4 inch length to go horizontally through the cover sides and locate into the rubber mounts. Actually I have one or two spares 1″ long as they sometimes make it easier to line up into the rubber mounts. It takes some patience to get the covers lined up so the screws go into the rubber mounts but you will see as you go.

These motors are fun to run but really vibrate and I usually have a couple spare screws aboard.

April 27, 2020 at 3:27 pm #201228 -

AuthorPosts

- You must be logged in to reply to this topic.