Home › Forum › Ask A Member › Johnson TN28 Carbon Seal Upgrade

- This topic has 10 replies, 2 voices, and was last updated 3 years, 11 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

February 18, 2022 at 2:30 pm #254861

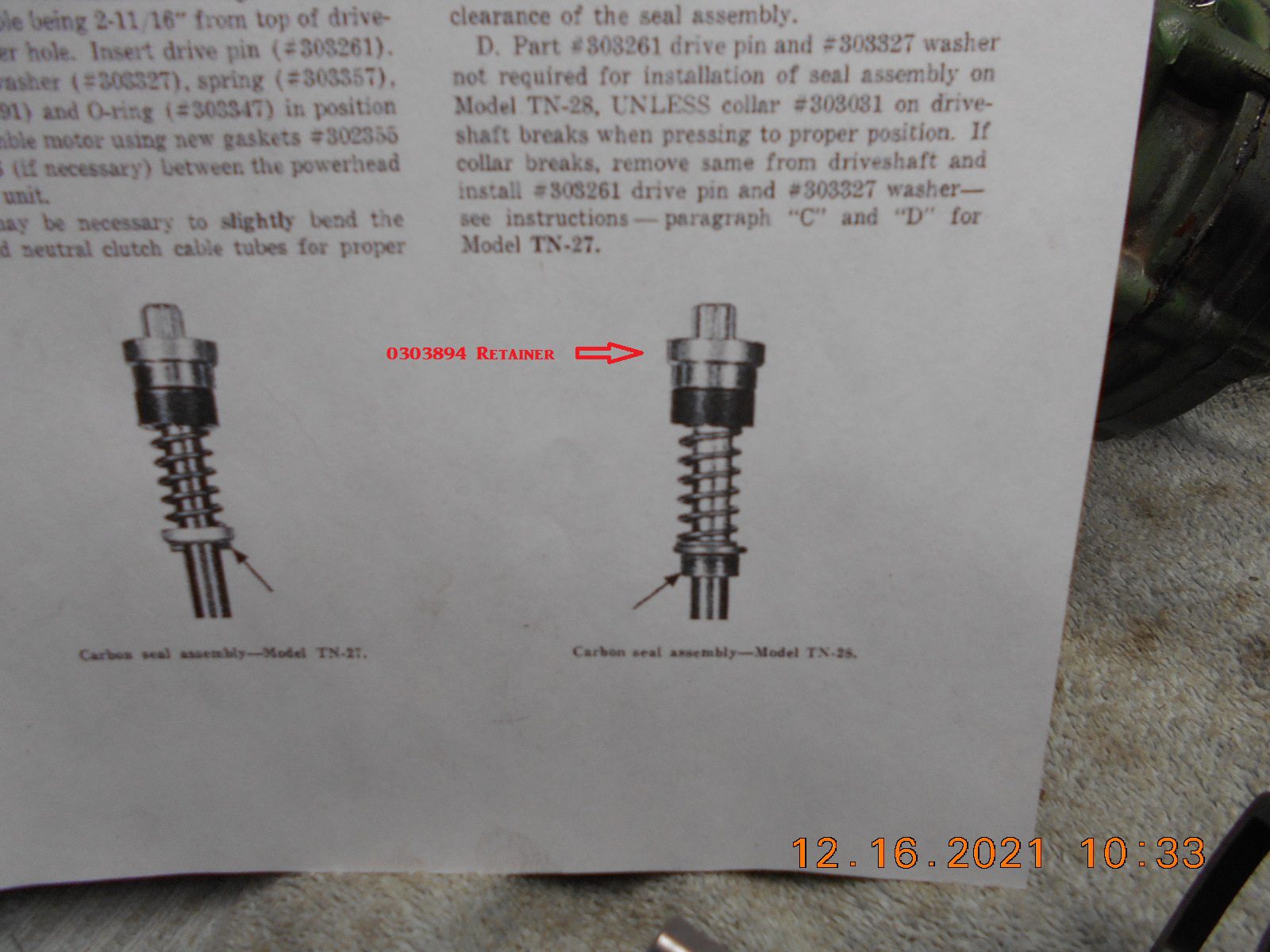

Anyone have a photo of, dimensions, or an actual part #303894

called a “Retainer” in the photo below?I thought I was missing the (original style) carbon seal spring on this project,

and ran across the Johnson Service Bulletin “Carbon Seal Upgrade”

for the TN28. I read where later models used the same carbon seal as

the upgrade bulletin, hence I ordered a used carbon seal assembly

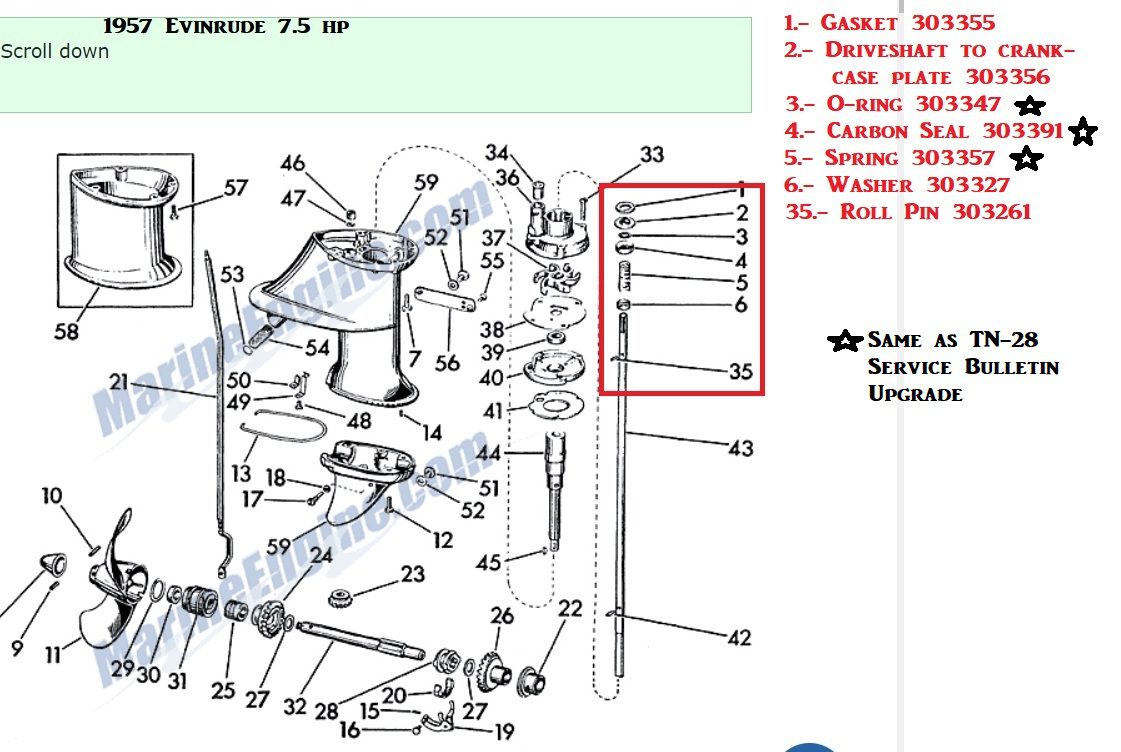

from a 1957 Evinrude 7.5 hp.It turns out that the only parts in the assembly I ordered that are the same

as the bulletin, are the “carbon seal, spring, and o-ring”.While awaiting the carbon seal assembly to arrive, I thought I’d move the

pressed on collar (on the driveshaft) to the 2-5/8″ position from the top

of the driveshaft, per upgrade instructions. This did not go so well,

and I ended up making a new collar on the lathe.After that, the mail showed up with my used 1957 carbon seal assembly.

As noted, the parts mentioned above are correct, but the “drive shaft

to crankshaft plate” (washer like thingy) for the 57 assembly, does not

work on the TN.

I should have done a little more research, as what I have won’t work

without the missing retainer shown in the Service Bulletin.

I can probably make one, but it would be nice to have an actual photo,

with dimensions, even better!It appears that the original carbon seal actual rode of the bottom of the

rotating crankshaft. Is this correct?

It appears that the upgraded carbon seal does not come in contact with

the rotating crankshaft end, but rather the missing retainer.It also appears that the original assembly was totally worthless as far as keeping water of

of the crankshaft splines, as there’s a big gap between the carbon seal

ID and driveshaft. The TN parts manual does not suggest that I’m

missing any of the original parts.

I’d like to make the upgrade work, as the original setup evidently

wasn’t too good, hence the upgrade bulletin.

Thanks for any help.

Prepare to be boarded!

February 18, 2022 at 2:33 pm #254867P.S.- Needed retainer above shows up on Marine Engine as S.O.L.,

and I don’t find one on EBay either.Photo to show just how sloppy the original carbon seal is around

the driveshaft. I don’t understand how it would keep any water

away from the driveshaft splines, but I have to say, the splines

were not rusty or stuck at all when it was taken apart.Perhaps I’m not understanding something?

Prepare to be boarded!

February 18, 2022 at 3:08 pm #254874Buc, That can’t be the right seal for that motor..the seal is supposed to seal water out of the crankcase and splines I’ve always thought. That seal will do neither. And aren’t the splines supposed to go all the way into the crank so the seal is sealing against the smooth part of the driveshaft? Something just doesn’t look right there.

February 18, 2022 at 3:36 pm #254875Dan, I’m as confused as you are, lol

Prepare to be boarded!

February 18, 2022 at 8:00 pm #254891This is what the retainer I’m missing, actually looks like.

I guess I can calculate the total height of the piece, as I know

it needs to compress the spring so the carbon seal’s o-ring

is below the crankshaft splines.What I’m wondering is, should the OD of this retainer be

a snug fit in the LU housing, or free floating.

If it’s “free floating” in the housing, then the top of the retainer

will come in contact with the bottom of the spinning crankshaft.

The “upgrade diagram” in the previous post above, is showing

a “gap” between the retainer and bottom of the crankshaft, making

me think the retainer fits snuggly in the bore.Thoughts?

Prepare to be boarded!

February 18, 2022 at 9:03 pm #254904Is there a ridge on the inside of your crankcase or is it possibly beveled? Your spring and seal assy. have to be the wrong ones…the spring should be closer to the driveshaft size I would think and obviously the seal needs to be smaller. Since I have never had one of these apart I really have no idea what it’s supposed to look like…I’m surprised there is nobody out there that knows what it’s supposed to be.

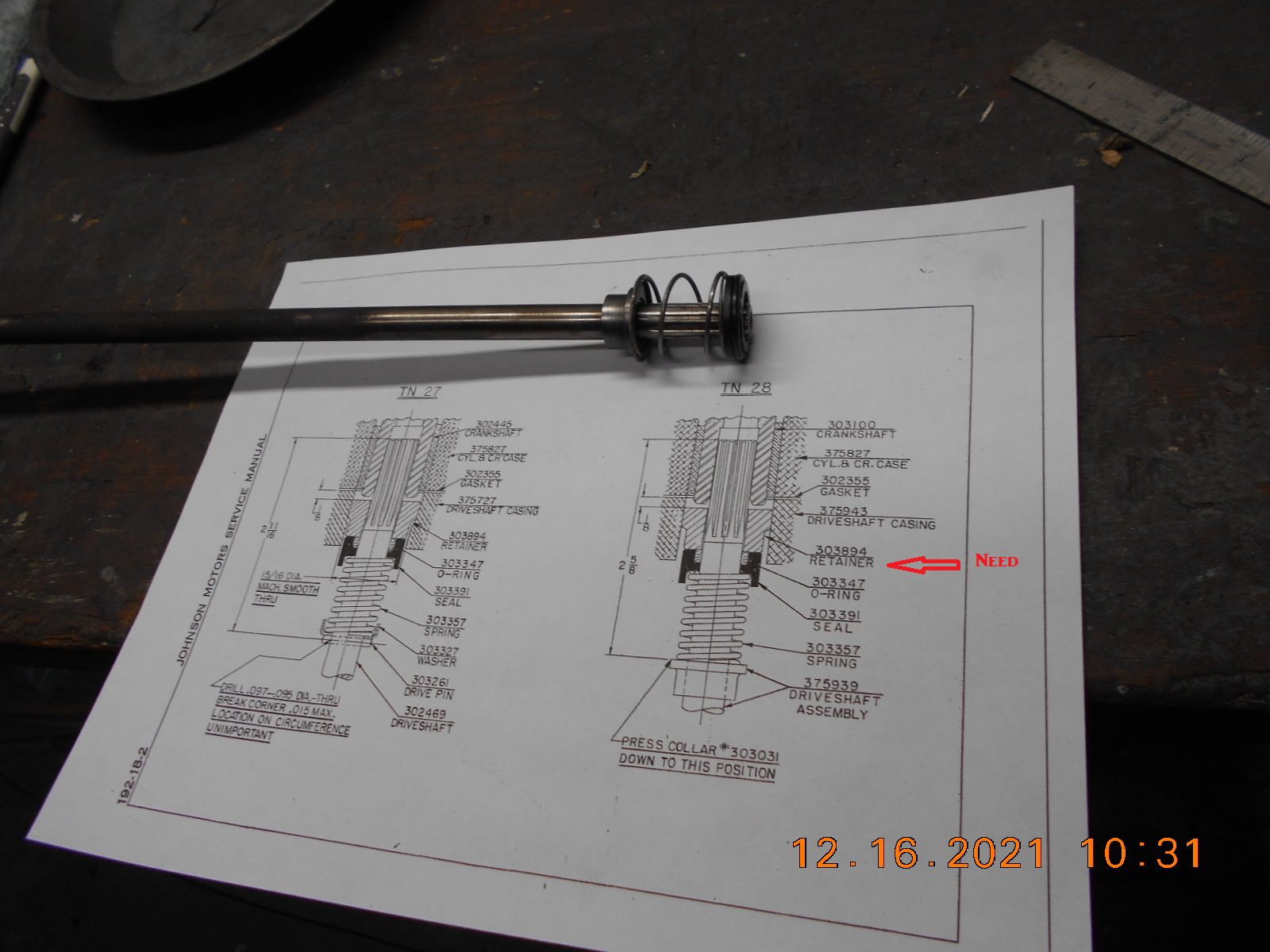

February 18, 2022 at 9:41 pm #254907Dan, sorry for the confusion. The photos were showing the old, original carbon

seal assembly, and I was wondering how it could have ever worked.My problem is coming up or making a retainer like shown in the TN28 “upgrade” sheet,

so the new style spring, and carbon seal (from a 57 Evinrude) work in the TN.This photo shows the new parts on my TN driveshaft, and that the “plate” and gasket

from the Evinrude, do not fit my TN’s housing.

Prepare to be boarded!

February 18, 2022 at 9:55 pm #254912I like the looks of that top plate and gasket…with your keen lathe skills can’t you make a plate that would fit inside the lower crank case and fabricate a gasket to seal the plate to the crank case…looks like the last photo shows a plate with a shallow lip that could fit into the bottom of the crank case. That plate/gasket/seal and spring would stay stationary and the driveshaft would spin inside the carbon seal/oring. That’s what my peabrain sees anyhoo…lol.

February 18, 2022 at 10:03 pm #254913I found this photo online of an original TN27 Carbon Seal Assembly

in the housing. The carbon seal mates up against the rotating end

of the crankshaft. While it may keep water from getting into

the crankcase bottom bushing, it would not keep water out

of the driveshaft / crankshaft splines, as the hole in the center

of the carbon seal is much bigger than the driveshaft.

There is an o-ring on the OD of the carbon seal, but

not on the ID of the carbon seal, like later seals had.

I presume this is why Johnson put out the service bulletin

for upgrading the seal assembly.Prepare to be boarded!

February 18, 2022 at 10:06 pm #254917I like the looks of that top plate and gasket…with your keen lathe skills can’t you make a plate that would fit inside the lower crank case and fabricate a gasket to seal the plate to the crank case…looks like the last photo shows a plate with a shallow lip that could fit into the bottom of the crank case. That plate/gasket/seal and spring would stay stationary and the driveshaft would spin inside the carbon seal/oring. That’s what my peabrain sees anyhoo…lol.

I can make the stepped retainer like the upgrade bulletin shows,

I just don’t know if it should be free floating in the housing,

or a press fit down in the housing bore a ways so the crankshaft

end doesn’t rub on it.Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.