Home › Forum › Ask A Member › K35 Mag Plate Repair?

- This topic has 5 replies, 3 voices, and was last updated 3 months, 2 weeks ago by

Tubs.

Tubs.

-

AuthorPosts

-

October 28, 2025 at 1:03 pm #301011

If I didn’t have bad luck I’d have no luck at all…

Good Day,

Long story, two different mag plates have let go (prior to me touching them) at the collar clamp area. This is the best of the two for repair as far as I can tell.

Thoughts on:

How to repair

Will JB handle this if I am gentle during assembly?

Do I need an aluminum welder to repair for me?

How about a slice of alum stock under the gap and a couple of small holes drilled into the plate (through the collar), tapped to a small dia. and screws set in epoxy? Once dry, grind off the screw heads?

Anyone willing/able to give that last one a try for a few bucks?

Thanks,

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

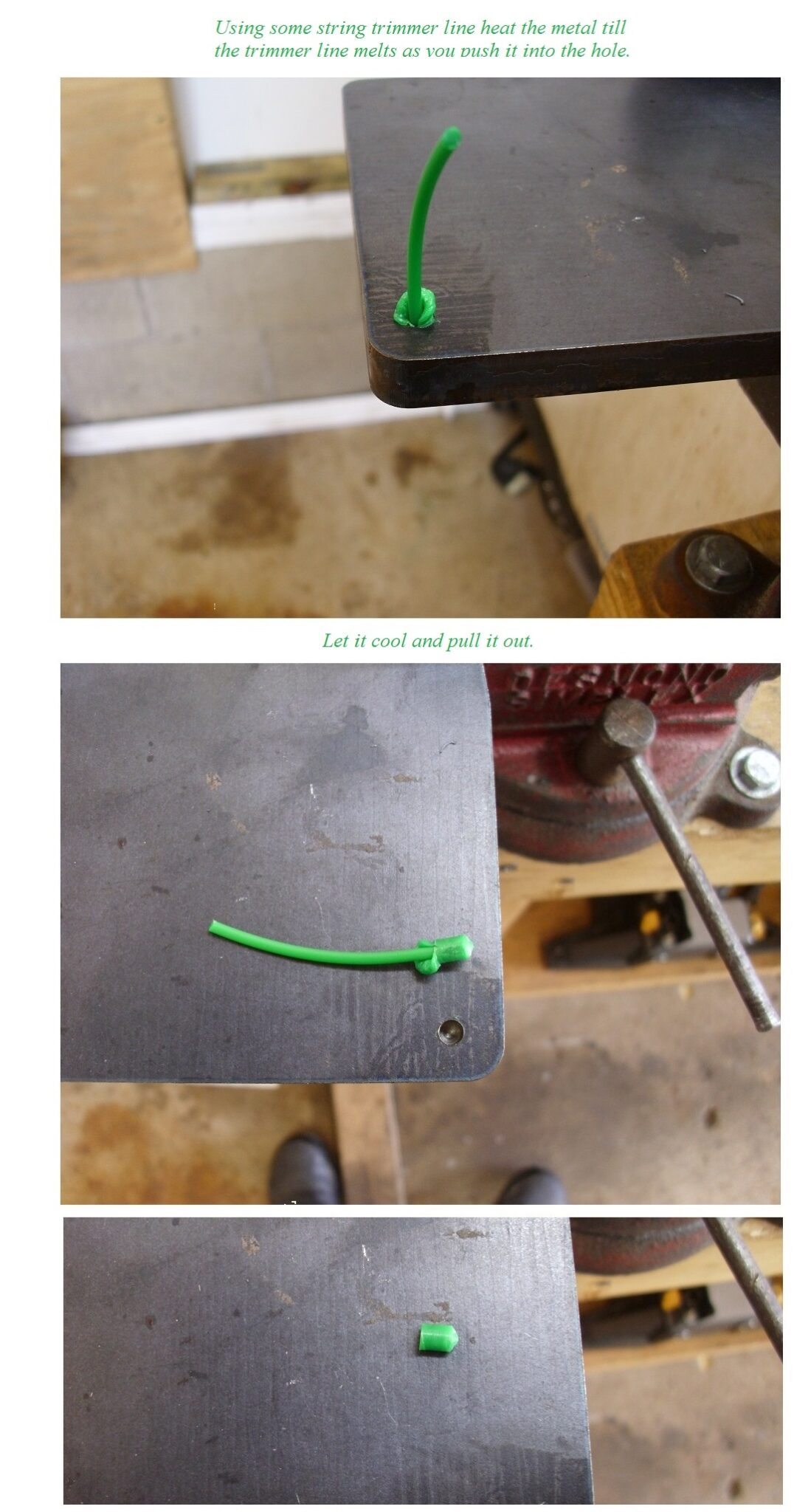

57 Johnson RDE-19October 28, 2025 at 1:55 pm #301016Something I might try myself some day in your situation, is to alumi-braze

that piece back on, but don’t use that clamping bolt anymore

to tighten the mag plate.

Instead, one could drill and tap a hole in the “unbroken” portion of the ring,

and use some kind of friction plug, i.e., a nylon bolt.

Anyone think that would work?Prepare to be boarded!

1 user thanked author for this post.

October 28, 2025 at 3:05 pm #301019Something I might try myself some day in your situation, is to alumi-braze

that piece back on, but don’t use that clamping bolt anymore

to tighten the mag plate.

Instead, one could drill and tap a hole in the “unbroken” portion of the ring,

and use some kind of friction plug, i.e., a nylon bolt.

Anyone think that would work?I really like that idea. Might add a thin stainless collar (think about the modern (40’s / 50’s mags) so the plastic nut is not riding directly on the powerhead boss, instead the bolt is putting indirect pressure on the boss. Eliminates wear on the plastic nut.

Good idea, or no?

Thanks Buccaneer!

What does the group think?

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19October 28, 2025 at 10:57 pm #301030with a collar installed, will the mag plate still fit on the boss of the powerhead?

If so, that would work I think.Prepare to be boarded!

October 29, 2025 at 12:22 am #301032Not sure, good thought.. I have some different size thin stock i bought for setting my late 40s coils (TD20, etc). I’ll add the shims to verify i have room. Thanks

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19October 29, 2025 at 10:05 pm #301065 -

AuthorPosts

- You must be logged in to reply to this topic.