Home › Forum › Ask A Member › KD4

- This topic has 6 replies, 5 voices, and was last updated 3 years, 6 months ago by

Tubs.

Tubs.

-

AuthorPosts

-

July 22, 2022 at 2:17 pm #263409

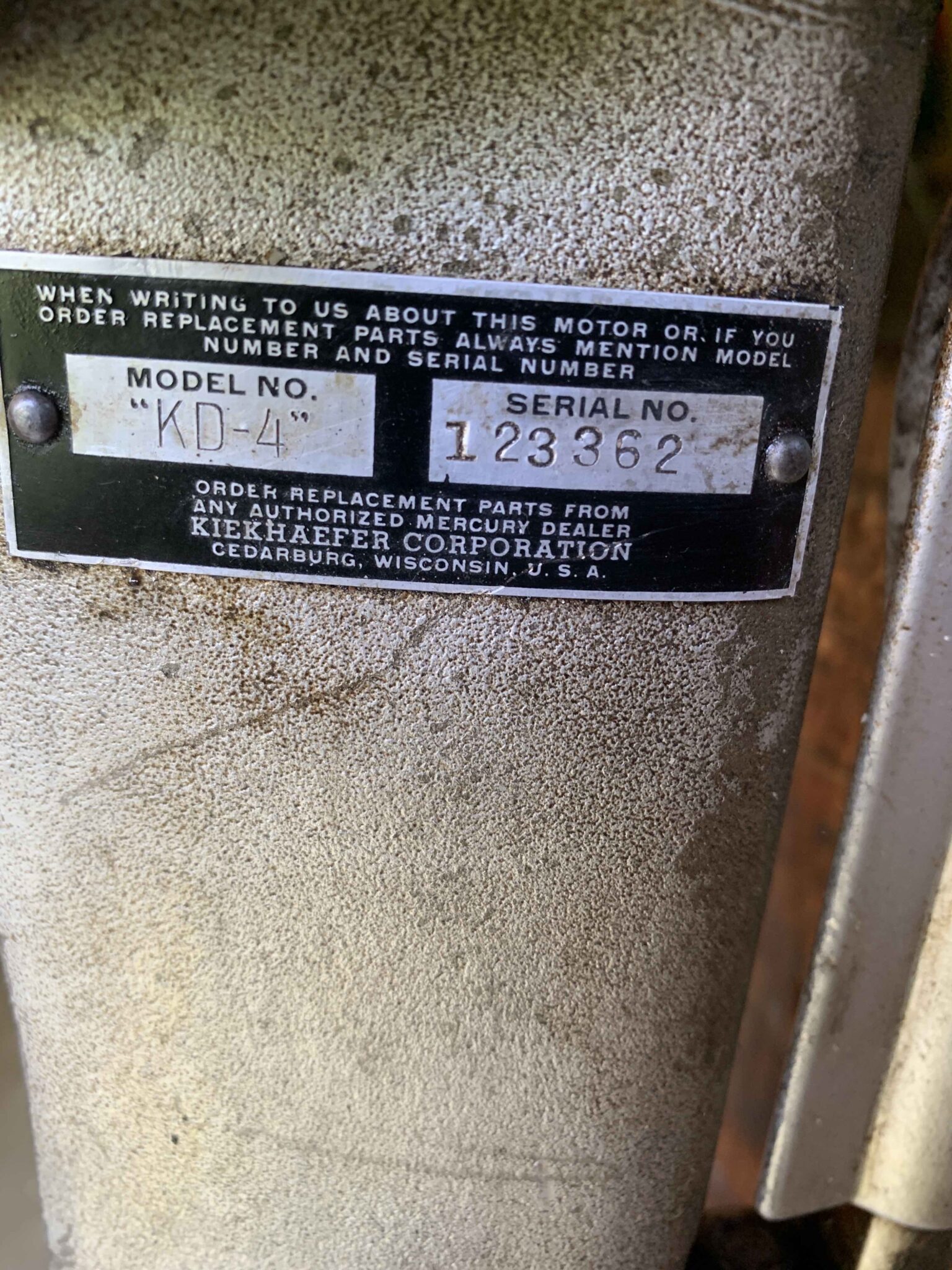

Hi all , I’m working on a Mercury KD 4. Right out of the gate , it has a great spark. How ever…… my prop is stuck on the prop shaft. Prop is already damaged. I’m already soaking with PB blaster. Tried to budge it with my manual arbor press. Not moving. Am I cutting the prop off? Please share your suggestions .

-

This topic was modified 3 years, 6 months ago by

Matthew Pieklik.

-

This topic was modified 3 years, 6 months ago by

Matthew Pieklik.

-

This topic was modified 3 years, 6 months ago by

Matthew Pieklik.

July 22, 2022 at 2:54 pm #263419try heat. And press. support under blades and use a nut on the prop shaft. leave it under pressure and come back later. nut protects the threads.

-

This reply was modified 3 years, 6 months ago by

dave-bernard.

dave-bernard.

-

This reply was modified 3 years, 6 months ago by

dave-bernard.

dave-bernard.

1 user thanked author for this post.

July 22, 2022 at 5:33 pm #263435Not uncommon problem. Level of difficulty ranges from not so bad to IMPOSSIBLE, The last time I tried I wrecked prop, prop shaft and took a nip out of water pump.

IF you have access to a lathe with both headstock and tailstock chucks, I would suggest mounting the assembly in tailstock and drilling out the prop shaft up to the sheer pin, Prop shaft is NOT hard s9 this is doable. Not much more than first using a center drill and then drill with small drill, the slightly larger drills until done. Unfortunately, by time this method came to mind I had already trued a brute force method.

7 slits mean an Oscillator type water pump

Note that drilling the prop shaft destroys the least expensive part in order to save most of the rest. Set up shown whoulc work.given all the lathe items.

Louis

Note #2 A center drill is a special purpose drill used to drill a dimple in center of object held in chuck of lathe or mill. It is a short stubby body drill that will resist bending and wandering. Standard drills will then stare in center dimple and will tend to drill a straight hole in center. Drilling thru with progressively larger drills will enlarge the hole to point the last and largest drill will remove a thin shell of metal.

The 3/16 hard steel pin can be driven out and the prop shaft gear can be removed with some ingenuity and effort to give the tailstock chuck more purchase to keep the axis of prop shaft assembly in line with axis of headstock chuck. Once the center drill has established the center dimple the drill tends to keep things aligned.

.Further edit…the tool made from a couple items from scrap box and a lot of nuts and bolts worked on mildly stuck props, BUT, failed miserably when confronted with a REALLY stuck example. After cutting prop away from prop shaft the cause was revealed….rust swollen prop shaft had a grip on prop that that a 12 ton press could not budge.

Louis

-

This reply was modified 3 years, 6 months ago by

green-thumbs.

-

This reply was modified 3 years, 6 months ago by

green-thumbs.

-

This reply was modified 3 years, 6 months ago by

green-thumbs.

1 user thanked author for this post.

July 23, 2022 at 5:41 am #263465It can’t be stressed enough that if you’re going to try to press it or hit it, you MUST use a nut on the shaft. It is very soft and the threads and even the cotter pin hole will fold up like butter.. I guess that if it were me (and it HAS been) I would start by getting an expendable nut and put it on the shaft, down to within an eighth inch of the prop. Then I would heat the prop quite hot and hold it in my hand with welder’s gloves and try hitting the prop shaft and nut and see if you can get the prop moving that one eighth inch, to begin with. Don’t try to support the prop in a vise, as the blades will be damaged quickly. Make sure you hit the nut very, very squarely or the end of the shaft will bend sideways. Then you’ll be drilling it out, like Tubs says.

Long live American manufacturing!

-

This reply was modified 3 years, 6 months ago by

billw.

July 23, 2022 at 6:47 am #263469

It was green-thumbs that demonstrated drilling out the prop

shaft. That’s way above my skill level. If I could add to your

suggestion of using a nut to protecting the threads by including

a bolt as used to remove a flywheel that doesn’t have holes

for a puller.

Tubs.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

July 23, 2022 at 12:53 pm #263481That’s a good idea. Like a bang nut.

Long live American manufacturing!

July 23, 2022 at 3:34 pm #263484

These are from the internet. I believe the

ones on top were originally posted by Frank R.

The other is a tool for a specific motor but the

same principal. Just need to be checking from

time to time that the bolt is still tight.

Tubs.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

1 user thanked author for this post.

-

This topic was modified 3 years, 6 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.