Home › Forum › Ask A Member › Lower unit lubricant

- This topic has 8 replies, 5 voices, and was last updated 9 months, 2 weeks ago by

JACQUES.

-

AuthorPosts

-

May 4, 2025 at 8:18 pm #296178

Just picked up a sweet little 1967 Johnson 3 horse and am going thru it to make sure everything is copasetic before trying to fire it up. Removed the carb, disassembled, cleaned, and ordered a Sierra rebuild kit for it. Also tore into the lower unit and found the waterpump impeller to be in good shape. Lower unit had leaked most of the lube out so I replaced the O-ring and now need to fill with lube. I have a tube of Lubriplate and am wondering if that is appropriate for this use.

May 4, 2025 at 8:44 pm #296179it is my understanding that for non shifting GC lubriplate is ok or John Deere Corn Head grease….but

why not just refill with regular GC oil like the book says to do.

Joining AOMCI has priviledges 🙂

May 4, 2025 at 10:51 pm #296187

If the person who used it last didn’t drain the gear case to check for water, and all the gear oil actually did leak out, the gear case would need the seals replaced.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

May 5, 2025 at 12:29 pm #296206Unfortunately I don’t have a manual for this motor and can’t seem to find one for that particular model and year (1967, 3hp). Any ideas on where I might find such a thing? Also, what weight GC green should I use? The GC wasn’t completely empty but close to it and there was no water present. Do you still think I need to replace the sealsanyway Tubs?

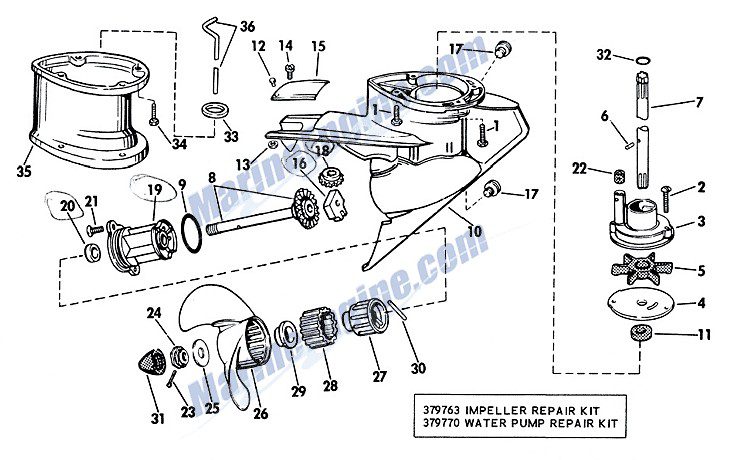

May 5, 2025 at 12:48 pm #296207Online manual here: https://www.marineengine.com/parts/johnson-evinrude-parts.php?year=1967&hp=3&model=JW-22

2 seals #11 and #20

May 5, 2025 at 8:13 pm #296217just fill with 90 grade GC oil …run it a week or two and recheck for water ingress. if no water recheck mid season and if none you are all set .

change the nylon crush washers under bolt #17 to seal the bolt face properly

if water comes in you have 3 options

learn and seal the GC

change the oil mid season

use lubriplate grease or john deere which is tolerant to water

Joining AOMCI has priviledges 🙂

May 6, 2025 at 9:57 am #296224I use marine gearcase oil in my 3 HPs that are like yours. Be sure to use Marine gear oil. Regular gear oil for cars does not have the additive to emulsify any water that gets in, which helps prevent rust and keeps it all in suspension, and lubricating until really a lot of water gets in. You may need the seal on the prop shaft – not the big O-ring you replaced. There is also a seal where the driveshaft goes in, under the water pump impeller. It’s these two seals that usually leak – not the O-ring.

Dave

May 6, 2025 at 10:07 am #296225Thanks to each one of you for your knowledgeable responses. This is what makes this organization so great – everyone willing to come along side those of us who need a bit of fatherly advice from time to time. You are an amazing bunch of grey beards!!!

May 6, 2025 at 10:27 am #296226here is a good way to know 100% if you need to replace seals.. about a 40$ investment on Amazon .

the pump does not come with the 3/8 16tpi thread adapter so look for a oil pump kit like the video shows. you can use it to pump your oil and…. supply the pressure adapter with the necessary thread adapter to pressurize the GC.

you can also to a VACUM test to confirm the seals work both ways !

my 75hp was tested perfect yet water got in one season … now I always use new nylons under the bolts !!

Joining AOMCI has priviledges 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.