Home › Forum › Ask A Member › Merc KE-4, 1947

- This topic has 25 replies, 5 voices, and was last updated 4 years, 1 month ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

November 13, 2021 at 9:28 am #249595

Points are no longer being manufactured. I know

of no source for new ones. If yours are unusable you’ll

need to get some from another motor.

Both ignition condenser # DR70T and AC Delco #D204

are suppose to have a value of have.18 to .23 however I

have never checked either. Tubs

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

This reply was modified 4 years, 2 months ago by

Tubs.

Tubs.

November 13, 2021 at 12:02 pm #249607if your points are straight spring. they can be had new , curved spring NO.

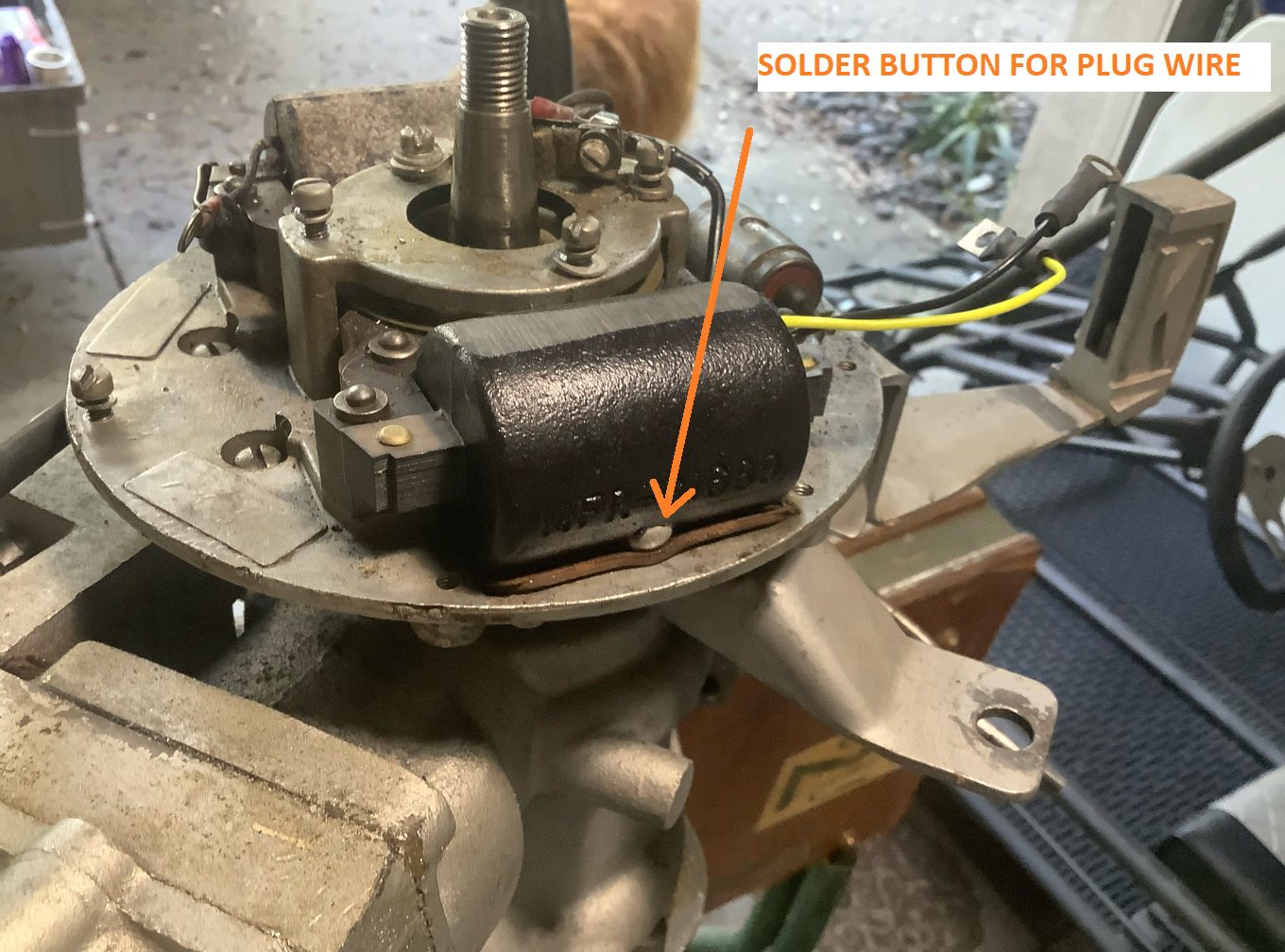

Spruce aircraft has themNovember 13, 2021 at 5:46 pm #249622I received these coils yesterday and they seem to match up except for one thing: the solder button, where you would attach the plug wire, falls dangerously close to the ignition plate at the bottom. It’s not exactly in the same position as the original coils, which I think, are scintilla coils. Does anyone know a way to get around this? Even with the rubber boot (that encases and insulates the plug wire from the housing on the bottom of the coil) attached, the soldered connection would be 1/8” from the metal ignition plate, which, to me….literally begs to short out. How can I get around this?

I might add that the coil could be rotated 180 degrees, which puts the solder button on top of the coil, but in that configuration it might invite clearance problems with the flywheel. I’m lost here.

As usual, any help is very valuable and deeply appreciated! Photo attached.

November 13, 2021 at 5:48 pm #249624I received these coils yesterday and they seem to match up except for one thing: the solder button, where you would attach the plug wire, falls dangerously close to the ignition plate at the bottom. It’s not exactly in the same position as the original coils, which I think, are scintilla coils. Does anyone know a way to get around this? Even with the rubber boot (that encases and insulates the plug wire from the housing on the bottom of the coil) attached, the soldered connection would be 1/8” from the metal ignition plate, which, to me….literally begs to short out. How can I get around this?

I might add that the coil could be rotated 180 degrees, which puts the solder button on top of the coil, but in that configuration it might invite clearance problems with the flywheel.

As usual, any help is very valuable and deeply appreciated! Photo attached.

November 13, 2021 at 6:05 pm #249627drill a clearance hole for it. then insulate

November 13, 2021 at 6:32 pm #249630I believe some people have soldered a copper strip to the button to route

where they want the plug wire to attach, then tape and insulate

the copper strip so it doesn’t arc.Prepare to be boarded!

-

This reply was modified 4 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.