Home › Forum › Ask A Member › Merc KE-4 7.5HP disassembly advice needed please.

- This topic has 9 replies, 1 voice, and was last updated 2 years, 3 months ago by

1bkshlf1.

-

AuthorPosts

-

September 24, 2017 at 6:10 pm #8308

I have 2 Merc KE-4s I acquired recently. I am having issues getting the motor swivel pipe/pin/tubing or whatever it is called out. I can see someone has tried to pound out the tubing from the bottom and pretty much chewed it up. Is these an easy/safe/better way to get these apart?

Second question: Is there a tool still available for purchase to take apart the gear box? Looks like a "T" handle that has 2 holes that go into the plate.

Thank you for your help

BillSeptember 24, 2017 at 6:49 pm #65330Removal of swivel pin: tap the hollow pin to create a threaded section (7’16" x 20 fine thread usually works. You may need to drill to correct tapping size. Then a section of all 7/16 x 20

threaded rod, nut, washer and a length of pipe, if it proves difficult apply heat and tighten

up nut…either swivel pin comes out or you pull the threads. Works for me.Removing the water pump cover: it is a LEFT HAND thread so it comes off the opposite way

There are several ways to soften up a tight cover…HEAT, BEAT and your favorite solvent

to seep into threads. The Mercury Service Tool can be made (sort of) but, the real problem

is corrosion between threads of cover and case. Use grease on threads when installing

cover.

Water pump housing has two threads so it can be (in theory anyway) be pulled out using

screws, nuts and a plate drilled to fit over prop shaft with holes for the two screws that

engage water pump cartridge. Usually the threads in water pump cartridge have been messed up so on to plan B. Pad prop shaft in vise and use soft mallet to drive gear case

assembly away from water pump cartridge…this will bring out several parts that have

to be reinstalled in same order…ALSO water pump cartridge has to be installed so inlet

and outlet are lined up or "clocked" Mark cartridge and case with magic marker or similar

to make this obvious when installing. Seal is installed in grease chamber side of water

pump cartridge and this is the way to get at it. Heating case may assist in removal and

installing. Cartridge is a friction fit in gear case. Take photos to aid in remembering which

parts go where. If you work carefully this should be a mild learning experience. It is vital that

you pay close attention when taking it apart so you avoid problems putting it back together.When you get it back together and it meshes and turns smoothly give yourself a pat on the back. It is not unknown for gears to be damaged or corroded, bearings to be rusted and

shafts to be be worn, grooved or rust pitted. It may be more cost effective to seek a good

used gear case water pump assemby than to track down gears, shafts and bearings.

Seals them selves are nominal cost but shaft has to be smooth. round and concentric to

seal lips…If you can make tools approximating the Mercury Service Tool life is easier.Louis

September 24, 2017 at 6:55 pm #65331In answer to your second question – yes, there is a special Mercury tool. However many Mercury mechanics make there own. It fits several gear cases. . . 😆

September 24, 2017 at 7:01 pm #65332

September 24, 2017 at 7:01 pm #65332Thank you Louis, I will give that a try.

Wow Garry. That is a great idea!

September 26, 2017 at 10:06 pm #65408Update!! That home made tool worked great for getting the cover off. Thank you Garry.

Louis, as for the rest of the disassembly, I am having issues. According to some technical info I found, after taking off the water pump cover, I should be able to "pry the impeller out with a couple of screw drivers" but that is not happening. It looks as if the impeller has a round clip holding it in place and I can’t get it to pry loose. I don’t want to pry too hard and wreck something.Also, I tried putting the propeller shaft in a vise and using a rubber mallet to coax it along. When that didn’t work, I tried a metal hammer and a block of wood. Nothing! Next is a torch.

Stand by…. (with a fire extinguisher)September 26, 2017 at 10:25 pm #65409If the impeller is shot and not reusable, cut the brass bushing with a Dremmel tool and remove. Save the key. That should ease things a bit. Clamp the prop shaft in a sturdy vise and using a big Mercury hammer and a block of wood, beat the hell out of it. Heat and a strong assistant help. 😉

(What it says in the Service Manual)September 27, 2017 at 1:00 am #65413Post a photo of impeller. Round clip does not sound familiar. I have not seen anything but

a pin on flat of drive shaft to lock impeller to shaft on KE4. Proceed with caution when

you encounter an unusual situation. The water pump cartridge is unlikely to have ever been

removed since it left factory so it can be a toughie .but, it is only a friction fit in gear case.

Torch may be best option. Be aware that the difference between not quite enough and way too

much of anything can be very slight.

LouisSeptember 28, 2017 at 12:16 am #65451I attached some pictures. The impeller looks good. At least what I can see of it. I’m not sure there IS a ring there. It kinda looks like one but it could be just the end of a bushing. or, something else. Either way, it looks like I get to heat it up. How can you not like fire and a hammer!

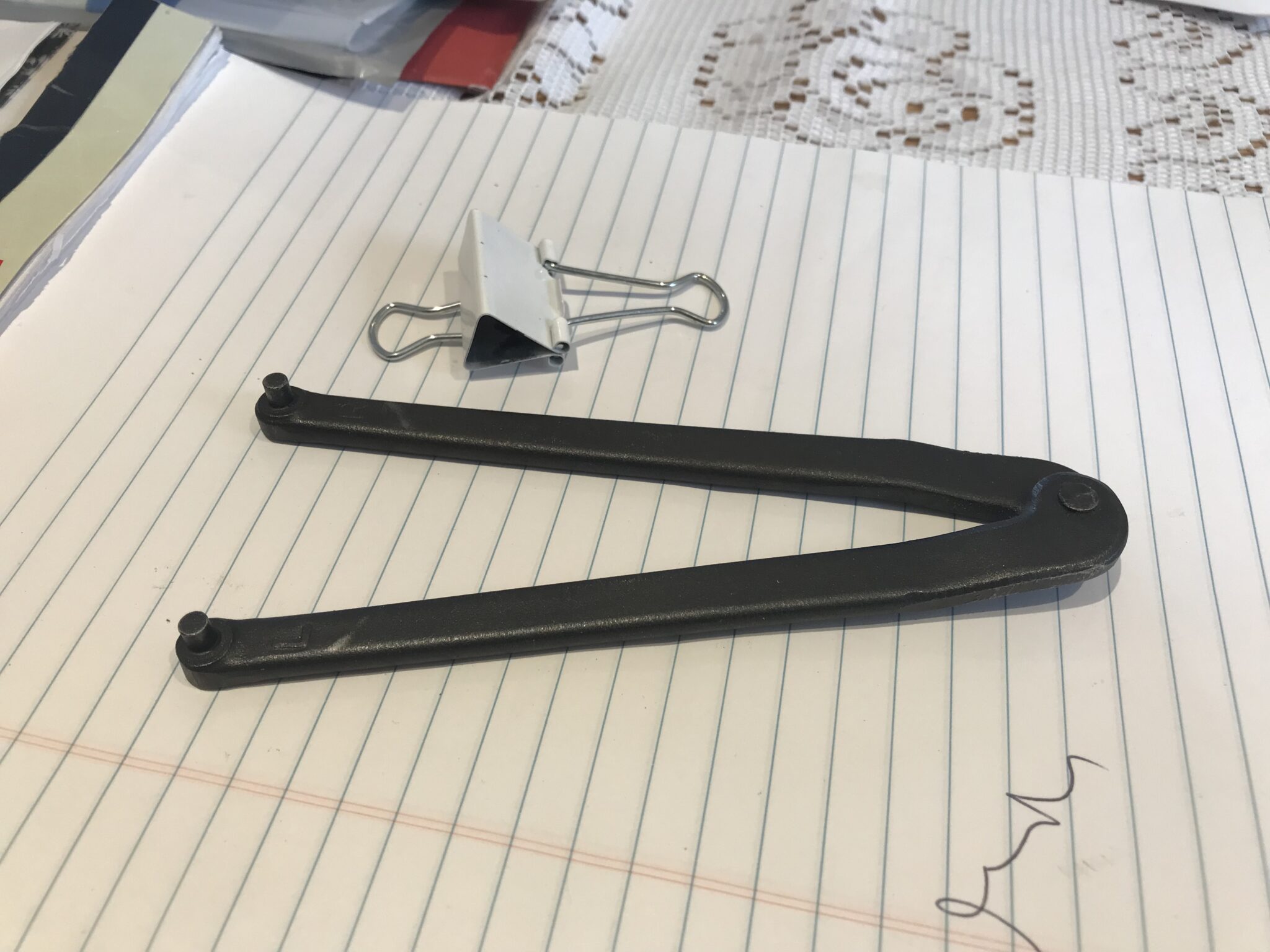

October 22, 2023 at 3:11 pm #281953I have a scanner wrench made by Wright tools (#9636, 2” model). It works perfectly. Its width is adjustable. Costs about $40 thru White Cap who is distributor for Wright tools. I needed to tap the end of the tool while holding the tines in the holes with other hand, but it worked perfectly. I ruined my Mark 20’s plate, but after I found this at a garage sale, I feel good about using it in the future. Here’s a photo or twO

Hope this helps

October 22, 2023 at 3:20 pm #281960It’s a spanner wrench, not a scanner wrench.

-

AuthorPosts

- You must be logged in to reply to this topic.