Home › Forum › Ask A Member › Mid-1970s 85 HP Johnson Remote Control Problem

- This topic has 16 replies, 2 voices, and was last updated 8 months, 2 weeks ago by

outbdnut2.

-

AuthorPosts

-

April 30, 2025 at 12:49 pm #295982

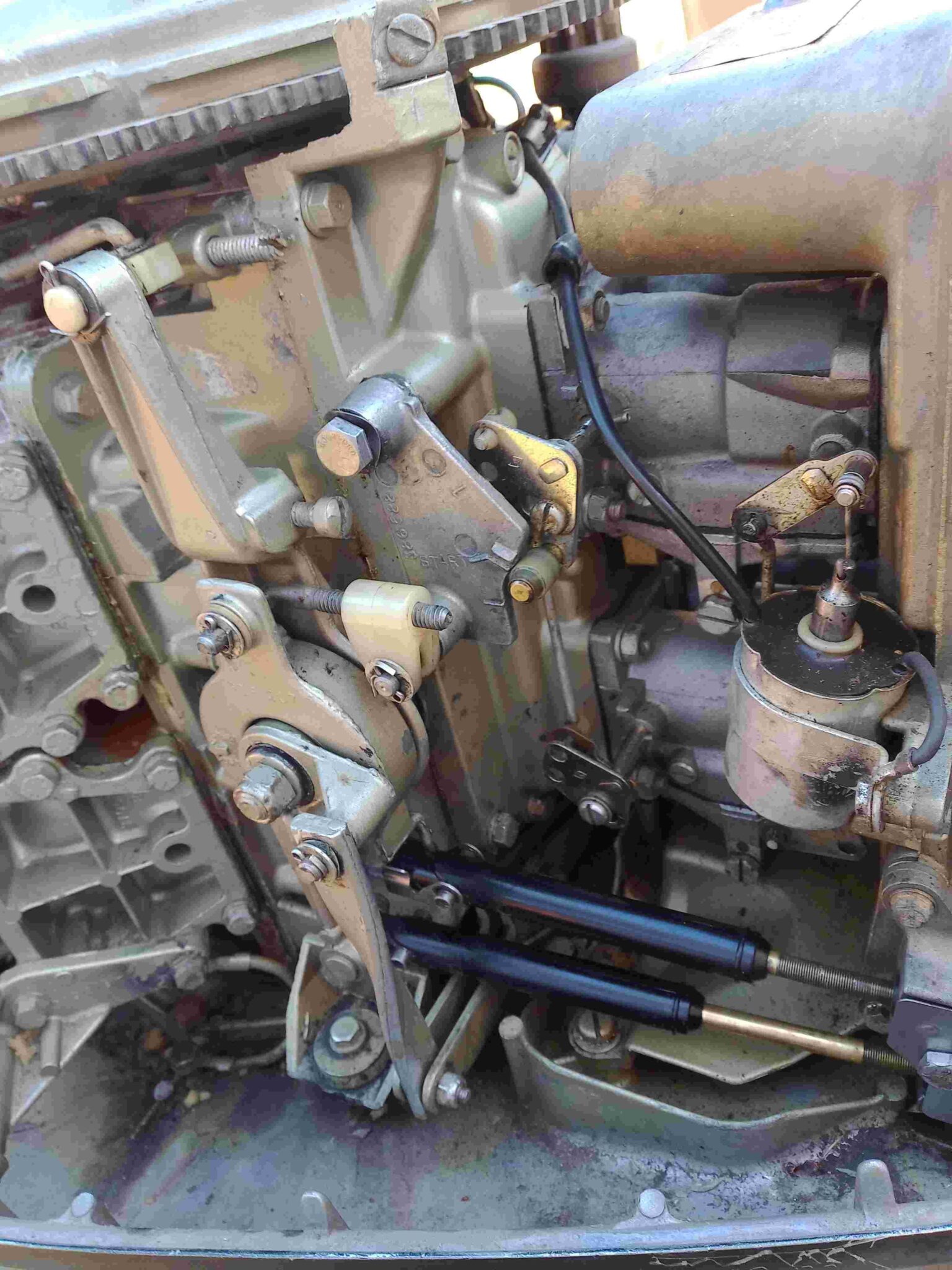

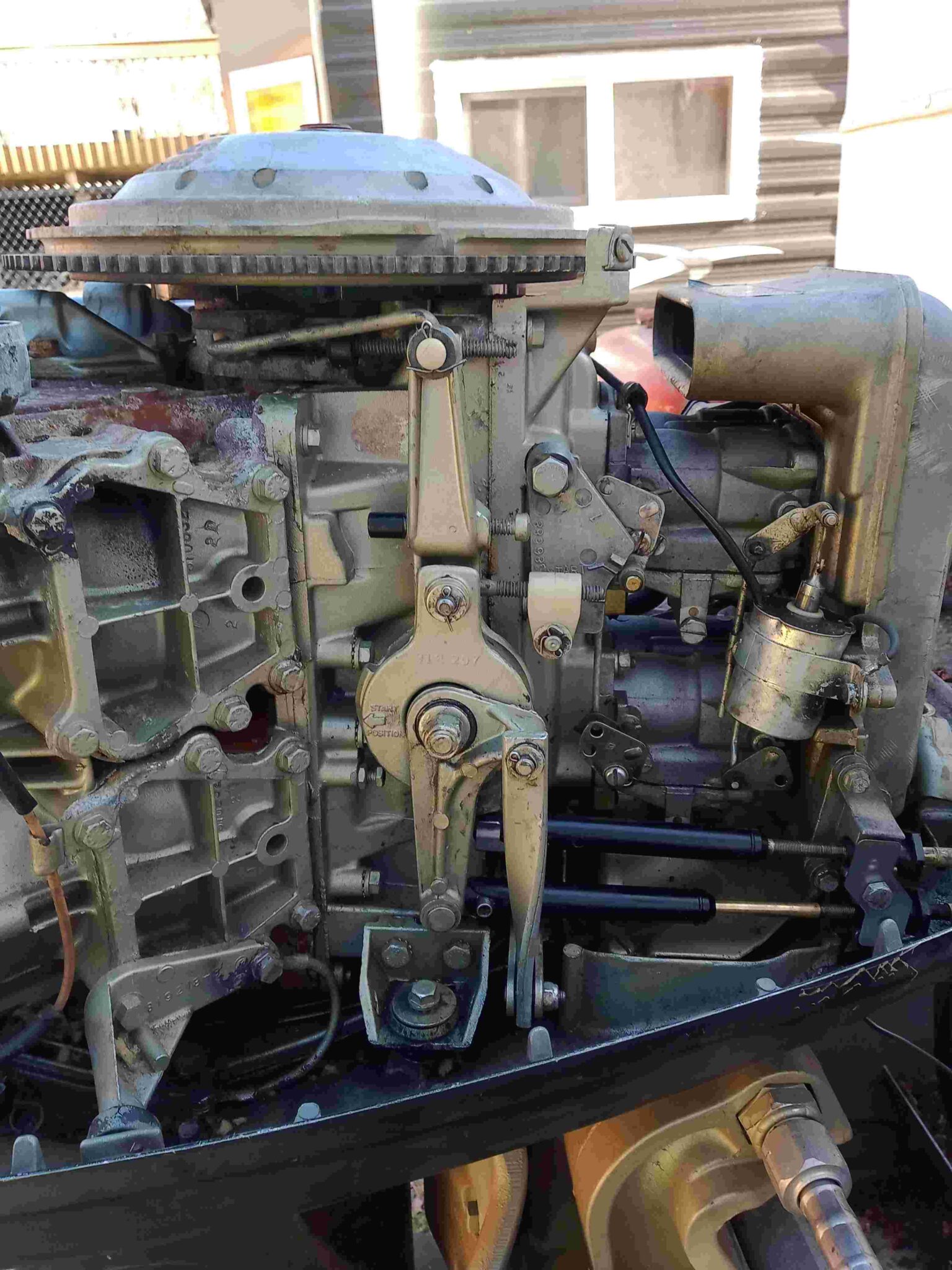

I’m helping a neighbor get an 85 HP Johnson (no model number found, but it matches 1976-1978 parts views, example model is model 85ETXLR77S). He just bought it from his brother and it hasn’t been run for a few years (Yeah ran good last time out on a different boat! How many times have I heard that?). I’ve never worked on a model like this before. The remote throttle/gearshift lever and the idle increase for starting lever barely move and will not move the motor’s linkage over the whole range without pushing the linkage by hand at the motor to help it along. Both the idle and throttle levers have separate cables, and the non-electric shift is linked at the motor from the main throttle cable motor linkage to a rod that goes to the gearcase vertically through the big steering pivot hinge. This motor has factory tilt/trim. The exploded views verify there is no electric shift. Here is what I’m seeing:

- When I disconnect the remote cables at the motor, the remote levers move the cable ends freely, so cables and remote box are not binding up.

- There is a big, round, wound spring on the linkage at the motor that tensions the remote idle lever movement – when I move that fast-idle lever linkage by hand with the remote cable disconnected, I can move it full range but the spring seems overly strong – should I spray some oil into the spring’s enclosure to get to move easier, or is there something else I should be looking for?

- The throttle is linked to the ignition plate under the flywheel for mechanical spark advance by a small rod, and that plate turns really hard – had to initially pry it with a big screwdriver to get it to move at all – haven’t pulled the flywheel yet, but tried spraying WD-40 all around it – loosened up some (can push it with fingers now with difficulty, but still seems way too tight. How do I loosen that up?

- Even pushing linkage and spark advance by hand with the remote cable disconnected, I cannot get the main throttle linkage to turn the carb linkage past about half way, although I can easily push the spring-loaded carb roller cam with my fingers to max throttle plate opening – Maybe could be due to shift linkage issue? – see #5 below. Note that two mechanical synchronization marks on the throttle linkage appear to be set so they line up with roller cam on one and an arrow on the other.

- When throttle linkage is manually pushed to full reverse or try to push to full forward, the prop still spins freely as in neutral at all positions I can get the throttle to move to – does this thing have to be running to make it shift and then will the linkage go all the way? The shift linkage I can see all moves OK up to where it goes vertically down through the steering hinge behind and below the carbs, where it moves some. Haven’t tried to start it yet, but have turned the flywheel a bit by hand – turns OK.

- Anything in all this throttle/shift mechanism and linkage that is know to be problematic?

- All thoughts appreciated! I used to have a 1965 V4-60 HP, but this is totally different. I will try to post a couple photos

- Thank You!

Dave

Link to exploded view of throttle/shift parts that are at lower right of the view: https://www.marineengine.com/parts/johnson-evinrude-parts.php?year=1977&hp=85&model=85TXLR77S&manufacturer=Johnson§ion=CYLINER+%26amp%3B+CRANKCASE

April 30, 2025 at 11:00 pm #296006OK, will try to address your questions. First, I just want to confirm that the control box/cables work easily/freely when disconnected from the engine…

Try this… Pop the horizontal rod out of the plastic coupling on the timer base, now try to move the throttle arm throughout its complete motion. That spring is pretty heavy making a little tough to push the throttle lever by hand, which is normal. Once the throttle arm is advanced fully, release it, the spring should carry it back almost to the closed position without having to help.

It would appear as though your timer base is stiff under the flywheel. Trying to spray lube under there probably won’t accomplish much, you will need to remove the flywheel and stator in order to get at the timer base. The timer base has a bushing that fits onto the upper bearing housing along with a plastic bushing bearing. Once cleaned up and freed up, the timer base brass busing is lubed with OMC moly lube, and the plastic bushing is lubed with outboard oil…

This engine has the gearcase with hydraulic “assist”, sometimes it can be tough to push that little lever completely into forward/reverse gear. Be sure to spin the prop while trying to shift as well…

1 user thanked author for this post.

May 3, 2025 at 10:10 am #296086Thanks for the help! Sometime Monday or Tuesday I’ll be working on it again. Per your suggestions, I’ll check out the throttle linkage with the timing advance disconnected, and pop the flywheel get the timing advance free’d up. I have a hunch that this motor has been dormant longer than the 2 or 3 years my neighbor was told.

Dave

May 5, 2025 at 9:49 pm #296218Hey Fleetwin – I’m making progress on my neighbor’s 85 HP , and have a couple more questions. Note that I verified it’s a 1979.

- I now have the throttle and shift linkage at the motor working well, except for the timing advance plate which is still hard to move. I pulled the flywheel and sprayed PB Blaster and it freed up slightly, but not near enough. To take it apart further, I have to remove the alternator stator ring. The Allen-wrench screws that hold it in are very tight. Are they good hardened screws so there is no danger of twisting/breaking them? Should I just use and allen wrench? or would an impact driver be better to loosen them up to avoid breakage?

- The remote control is not working right. It moves the cables without binding up, and the idle/start lever moves the throttle to the “start” cam mark in the motor like it should. It moves the carb to wide open fine, but the throttle lever will not come back far enough to shift to reverse. The remote throttel lever does not quite come back to straight-up positon, even with the cables both disconnected at the motor, otherwise the cables work fine going between neutral and forward without binding up,and to wide open throttle. Retarding the remote throttle lever gets it to neutral with the lever a bit ahead of straight up, and won’t come back any farther. Squeezing the button undeneath the handle on the throttle lever does nothing. The idle/start lever is all the way down where it should be, and in Neutral functions as it should to increase throttle to the start cam mark. Is the throttle/shift lever supposed to be straight up in neutral? – it’s a bit forward of that and won’t comeback farther. My neighbor and his brother had the remote apart before I ever saw it, so it may not have been put back together right. Am I correct that neutral should be straight up like all the other single lever remotes I’ve known? Even with the cables disconnected at the motor, the remote will not quite get back to straight up, and so doesn’t go to reverse, although with it disconnected, I can easily move the motor’s linkage by hand to reverse, but the remote will not move the shift cable to its reverse length, even with that cable disconnected at the motor. All this is with the rod to the timing plate disconnected, but holding the rod so the carb linkge doesn’t bind up on a big adjustment screw, so the motor appears to be OK. Before I take the remote apart, is there anything in the remote control box that is known to go bad on these? Anything I should look for where they could have screwed it up taking it apart before I was there? The piano wire in the remote cable doesn’t appear to be slipping in the cable ends at either end. Note that they may have forced the remote and messed it up internally when the timing plate was hooked up andnot moving before I was called on to look at it.

Thanks again for your help! I’venow learned a lot about the linkage in the motor!

Dave

May 7, 2025 at 7:28 am #296246OK, will try to address everything.

Yes, those allens screws are pretty tight, they might even have a little loctite on them. Yes, they are pretty tough screws, never broke one even in salt water. I would probably just use a good allen wrench (new one that isn’t worn), or perhaps an allen socket. In this case I would avoid the impact driver. You definitely need to remove that timer base in order to clean the bushings and relube properly.

I’m assuming you are probably using the stock single lever from back in the day. The big white box with the key/choke included, black vinyl pad on top. These things were not very good. There wasn’t a good lock out for the warm up lever, so whenever you pulled the throttle back and into neutral, the warm up lever tended to pop up a bit. Perhaps the cables are not tight in the clamps/retainers up in the control box causing slop/inconsistent adjustments.

Yes, the control handle should be straight up/90 degrees to the control box when in neutral. What do you mean when you say that the shift interlock does nothing? You don’t need to release the interlock when shifting out of gear into neutral, only when going into gear.

I suppose it is possible that the gear teeth are misaligned, but it seems like that would create quite a difference, more than you describe. The only other thing that comes to mind is that perhaps someone cut the inner cable wire too short when connecting/crimping the cables. This would make the control box bind up, difficult to shift, improper adjustment, etc…

May 13, 2025 at 10:44 am #296390Thanks for the additional info. I’ll be working on it again later today and I think I can finish it up now. The wire in the throttle cable had slipped in the cable end inside the remote control – It likely got forced with the timing base stuck.

One more question: What should the flywheel nut be torqued to? None of the lists I have go over 40 HP for torque specs.

Thanks!

Dave

May 13, 2025 at 1:38 pm #296399105 foot pounds! That slipped cable core would surely explain things. Keep in mind that the cable core is supposed to be “kinked” when tightened so it would hold its position even if the cable clamp loosens up.

Back off one of the set screws, now draw the other one in until it contacts the cable core/wire. Now give it another full turn if possible to “kink” the core wire. Once kinked, tighten the other set screw.

May 14, 2025 at 8:54 pm #296441After a lot of frustration taking apart the remote box and getting the couple big teeth meshing right, tightening a loose wire for a groundscrew, freeing up a sticky spring-loaded switch that cuts off starting when the lever is in gear, rerouting cables under the pontoon so they didn’t bind up, and lossening set screws on cable ends snd turning the ends so they didn’t have to be twisted (which adds friction inthe cables) to attach them; I now have the remote controls working great! Also have the timing assembly moving freely with hte throttle. I learned a lot about the remote controls for this type of motor. Thank you again for all the help! Other good news: it hadn’t been run for about 2 years and it started right up and idled good! (fresh gas and known good fuel line and tank used).

A couple more questions:

- I saw inside the remote box a device that I think is a buzzer, probably for overheating – is that right? Is it supposed to beep when starting to know it’s working? It does not, but not a big deal if it doesn’t work at all.

- Is the choke actuator supposed to have a return spring? It’s mounted vertical and seems to fall back with gravity and vibration, but no spring.

- This 1979 motor has factory power tilt/trim. The story with it says the hydraulic pump motor on it went bad and the former owner got the motor rebuilt, put it back on but couldn’t make the tilt work, the motor makes noise in one direction but not the other. Motor is all the way down now – is there a switch that shuts the motor off in the down direction when it’s all the way down? Where can I find a procedure for bleeding air out of the system?

- What is used for the hydraulic oil in the tilt/trim?

Thanks again!….and my neighbor thanks you too!

Dave

=

May 15, 2025 at 7:54 am #296448OK, the horn in this older control box is metal, correct? If so, it does not have a self test feature. It is a good idea to test it though which is simple to do. Spray some WD40 inside that rubber sleeve covering the head temp sensor so you can slide the rubber boot back. Now, with the key in the on position, simply ground the connection blades to the block, the horn should sound. No need to disconnect the bladed connection, just ground it. If you do disconnect the leads, be sure to ground the harness side of the lead, not the sensor side. True, this does not test sensor function, but it does test the horn and wiring.

Yes, there is usually is light spring inside that choke solenoid to ensure it returns to the open position.

OK, this is not a 1979 model, it is a 1973-77 model. Does it have power tilt, or the massive external power tilt and trim unit? There is no cut off switch when the unit reaches the down position, the pump motor will just slow down, I suppose it could actually shut off if the hydraulic pressure is too much for the electric motor.

The wiring is a little strange on these units. There is an “up” solenoid that ensures maximum current flow when tilting up. The down circuit is just wired through the power tilt/trim switch. So, if the unit does nothing when “up” is activated, perhaps there is an issue with the up solenoid or wiring to it. This up solenoid is buried somewhere in the boat, not on the engine.

You can use regular dexronII transmission fluid for this unit. The knurled fill plug is on the side of the electric pump. The unit is checked in the “up” position, but may be stuck down due to lack of fluid. Open the knurled fill nut, fluid should come pouring out when down. If not, fill it to overflowing. Once you get the engine tilted all the way up, check fluid level again.

May 27, 2025 at 11:52 am #296815Hey Fleetwin,

I finaly got around to looking more at the power tilt/trim problem – everything else is good to go now. (Note I found the model number and verified it’s a 1979 – I guessed before at 1973-1977 based on finding models with the same remote control in exploded views online).

The separate IN/OUT switch had all three wires mixed up on the switch terminals so that’s why it would only energize the tilt motor in the down direction. So after verifying wires and identifying terminals on the switch with an Ohmmeter, I have that working now, with “Out” tripping the solenoid and “In” switching directly as you described – THANK YOU!

So I can hear the trim motor running in both directions like it should now, but I can’t get it to move the motor. The story goes that the former owner said he took the trim motor off and had it rebuilt but couldn’t get it to work after that (I don’t know if the pump was removed with the motor and “rebuilt” or just the electric motor). I tried filling the pump through the screw on the side with dexron with the motor in both up and down positions. My neighbor (current owner) took the line off the top of the hydraulic cylinder and then was able to lift the motor all the way up as fluid shot out of the cylinder. It was fairly heavy purple liquid – not dexron, so don’t know what that was. Maybe Royal Triton motor oil?…it’s purple!

With a turkey baster, I tried putting dexron in the cyinder, in the line back to the pump, and filled the screw hole on the side of the pump, with the only fluid I could get in going into the hole on the side – that fill hole is full in manually set up and down positions of the motor. Nothing will pump, even with the line off the top of the cylinder. Is there a procedure for bleeding air? or having a line suck in fluid as it pumps? I’m stuck! Note that whatever was meant by the “tilt motor was rebuilt”, may or may not have had the pump assembly apart, or may have just been electrical, so the pump may not be right. I’d appreciate any tips on getting air out of the system and getting it to pump the fluid, and/or further troubleshoting.

Thanks Again!

Dave Stanton

-

AuthorPosts

- You must be logged in to reply to this topic.