Home › Forum › Ask A Member › modern pump 1956 10hp

- This topic has 6 replies, 4 voices, and was last updated 5 years ago by

crosbyman.

-

AuthorPosts

-

December 15, 2020 at 12:50 pm #225272

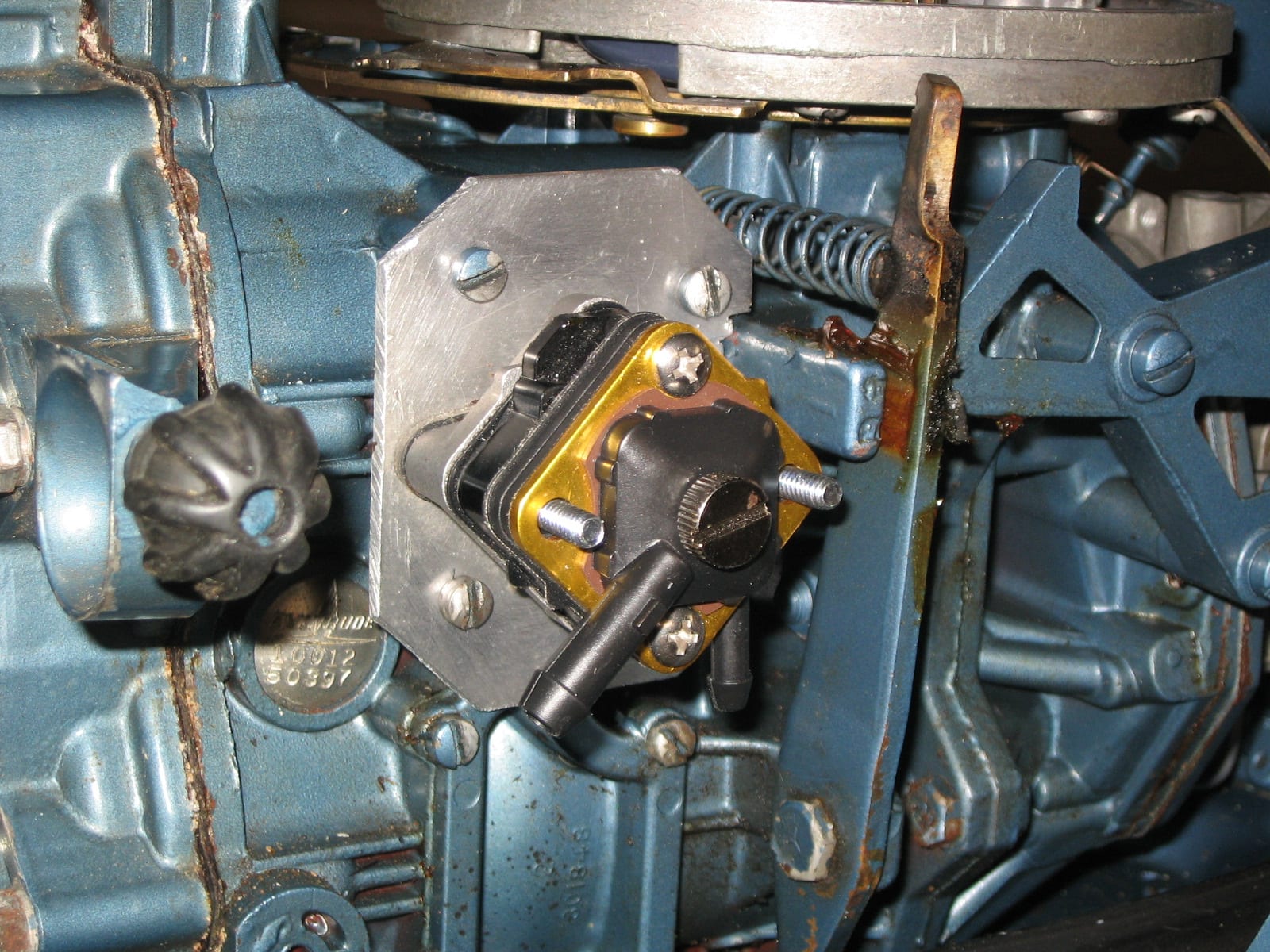

I installed a square pump to convert a 10hp but was wondering if by drilling the 1/4 ” hole in the side cover plate in the center (for a vacum pulse to the pump) if by any chance fuel-oil mix could fill the cavity behind the aluminum plate

would it be better to also drill a small drain hole at the bottom of the original cover palte so that any accumulated fuel-oil mix could drain/sucked back into the crankcase void instead of “filling up” behind the new plate and enterring the back side of the pump ?

Joining AOMCI has priviledges 🙂

December 15, 2020 at 12:59 pm #225279You could fill the original cover with epoxy or Bondo before drilling a small hole thru it. That would accomplish the same thing.

December 15, 2020 at 2:32 pm #225293I’m confused….Are you saying you used another bypass cover gasket between your aluminum plate and the bypass cover to seal that area? If so, I would follow Mumbles’ advice and just fill in that entire area, then drill the small hole through it lining up with the hole you have already drilled.

Perhaps you can find a 10hp bypass cover from a 60 or newer 10hp that has the fuel pump mounting already cast in place…December 15, 2020 at 2:39 pm #225294Rethinking it, I don’t see why a small drain hole, 1/6″ or so, wouldn’t work as it and the pulse hole would both feed to the same intake runner.

-

This reply was modified 5 years ago by

Mumbles.

Mumbles.

December 15, 2020 at 3:37 pm #225300Mumbles: Well I sealed up my aluminum plate to the cover plate with gasket goo (no gasket per say) so I think i’ll go with a small 1/16 3/32 hole in a bottom corner . Maybe I am overly worried. IF the engine performance seems affected for some reason i’ll just take everything appart and fill the cover void with epoxy

Fleetwin: I agree a bypass cover would be nice but I am just trying to keep costs as low as possible seeing I’ll resell the motor when opportunity knocks .

I just fix them up (electricals, coils if needed, etc… impeller, timing, plug wires boots etc.. and of course the carb.

I sell them at my cost plus parts $$ time is on me …4-5 hours on these is like a golf game to me. 🙂

thanks for comments

Joining AOMCI has priviledges 🙂

December 15, 2020 at 3:42 pm #225301I do what Mumbles suggested (fill it with JW Weld). In theory, that open cavity would add a few cc to the crankcase volume and affect engine performance, but you probably would never notice it.

December 15, 2020 at 4:22 pm #225303 -

This reply was modified 5 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.