Home › Forum › Ask A Member › Modifing outboard magneto to use an automobile point set

- This topic has 4 replies, 3 voices, and was last updated 1 month, 2 weeks ago by

green-thumbs.

-

AuthorPosts

-

December 20, 2025 at 11:58 am #302471

Has anyone looked into the subject? I do not recall any mention on this site or elsewhere. It seems like it might be doable in some cases. Finding room and setting up location of points are issues that come to mind, There have been lots of coil and condenser/capcitor discussions. It seems worth looking into whether automotive point sets are an option in at least some applications,

Louis

December 21, 2025 at 9:02 am #302495I would imagine that in most cases it’s mainly a matter of determining the best position for a non-stock set of points to get installed into, then drilling/tapping the holes for retaining screws in the best location(s), if its necessary. Points don’t care where they’re installed, they’ll do what they’re designed to do in any installation. BUT – If space is a concern, some of the smaller point sets used in chainsaws or snowmobile engines might be better options. Car/truck distributor points would probably require the most space and therefore mist not be the best choice, although the earlier magnetos like the Quick Action, Eisemann, and American Bosch magnetos used relatively large contact point assemblies. All depends on what you’re working on, I guess.

PM T2

He's livin' in his own private Idaho..... I hope to go out quietly in my sleep, like my grand-dad did..... and not screaming, like the passengers in his car...

December 21, 2025 at 11:12 am #302498

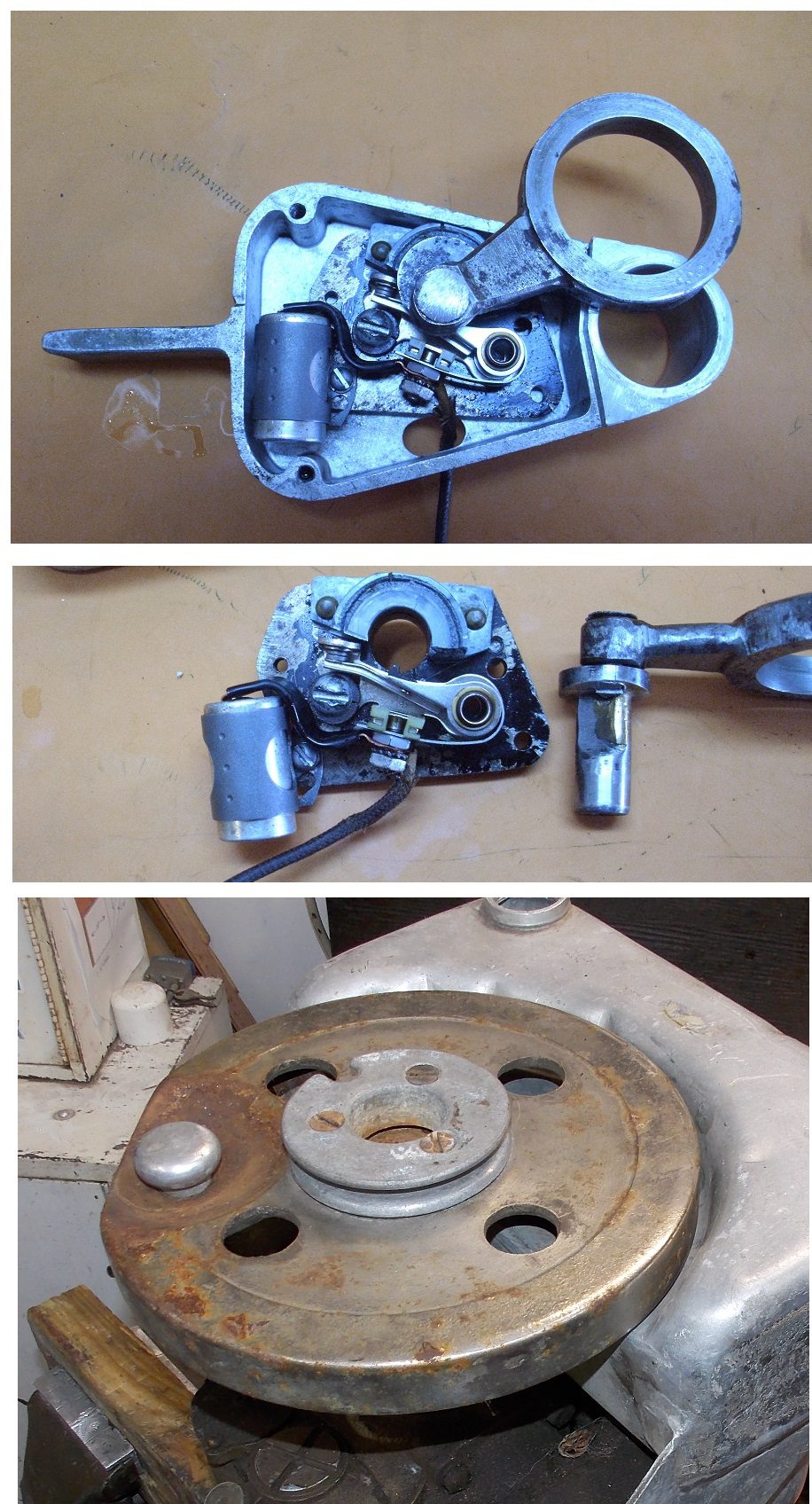

Here is an attempt to use some automotive points in a Atwater Kent timer. I suspect they found a disintegrating timer bushing, and not knowing how to resolve that issue, decided to adapt this set of automotive ignition points. If this motor would run, I didn’t try it, you wouldn’t be able to start the motor as intended, by bouncing it off of compression. It also would no longer run in reverse. It could only be started by spinning the motor in the forward rotation. It did have one of the factory rope pulleys but they are so small in dia. they are barely usable if the motor has close to new compression. The only thing salvageable from the original ignition was the timer case. Everything else was ruined.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

December 22, 2025 at 10:36 am #302525While on the subject of A-K timer bushings ( which frequently are found to be bad) … here is the print for fabrication. Either aluminum or brass is OK

Joe B

1 user thanked author for this post.

December 30, 2025 at 2:43 pm #302808T2, Tubs & Joe. THANK YOU for your considered and helpful responses. I was not able to find specific information only advice to buy a solid stete conversion kit, It seeems to me that there is no reason it can not be done if a suitable point set can be position on stator plate in the right position,. It would seem to boil down to drilling and taping holes in stator to located point set, . As they say

in Real Estate Location, Location, Location

Louis

U

-

AuthorPosts

- You must be logged in to reply to this topic.