Home › Forum › Ask A Member › Need help in installing needles and liners in 1.5 hp johnson outboard

- This topic has 13 replies, 7 voices, and was last updated 8 years, 6 months ago by

vito91256.

-

AuthorPosts

-

June 30, 2017 at 10:58 pm #7486June 30, 2017 at 11:28 pm #60692

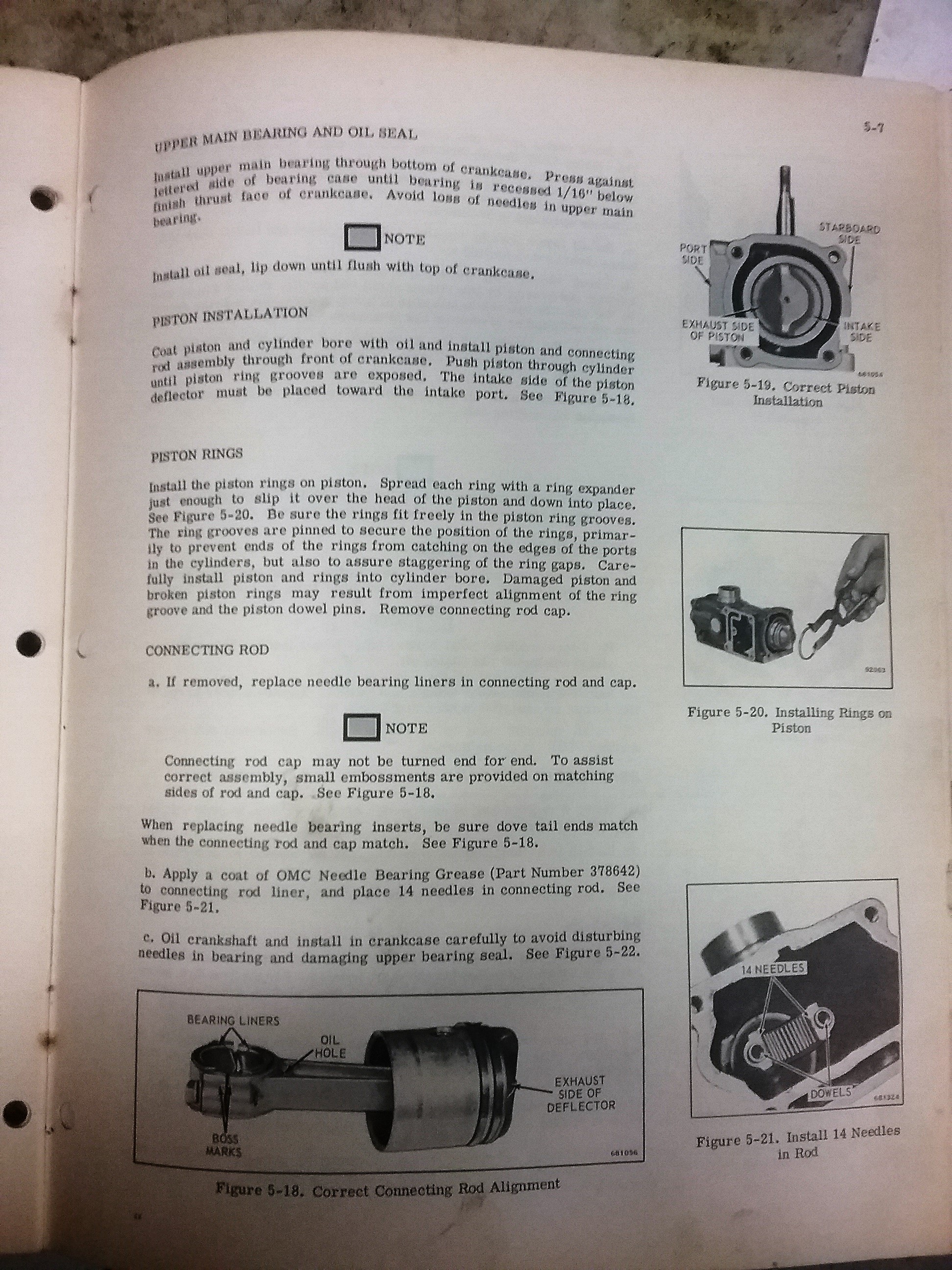

Use assembly grease to hold them in place , and make sure you have all of them. I have a service manual here somewhere. I will see if I can find it...

July 1, 2017 at 12:03 am #60693Vito, Clean those needles in a solvent to take off the wax that those pieces were packed with. As pointed out an installation grease will hold needles in place. I use Vasaline. Others may suggest something else, but you get the idea. Ed

July 1, 2017 at 12:06 am #60694I have them clean but how do you press the liners on to the needles and rod end , since the needles are slightly longer than the liners.

July 1, 2017 at 12:08 am #60695Also how do you center the liner when you have 15 needles on the rod end.

July 1, 2017 at 12:19 am #60697July 1, 2017 at 2:51 am #60704After cleaning all of the needles, lay them out on a clean cloth or white paper towel. There should be 29 of them. I like to lay them out in little piles of five with one pile of four left over. If you don’t have proper needle bearing grease to hold them in place, Vaseline will work and is better than grease as it will get washed out as soon as the motor is started. Grease can linger and plug the oil holes. If it’s hot out, stick the Vaseline in the fridge for a while to stiffen it up.

Coat the rod liner and lay in about half of the needles before snugging it up to the crank. Now the crank journal can be coated and the rest of the needles laid in place on the journal. A set of tweezers comes in handy for doing this. Just make sure the liners are installed so the cap can be installed correctly with the index marks lined up and also make sure all 29 needles are accounted for. Dropping one into the motor and not realising it could be disastrous.

July 1, 2017 at 1:34 pm #60735Thanks for your help.

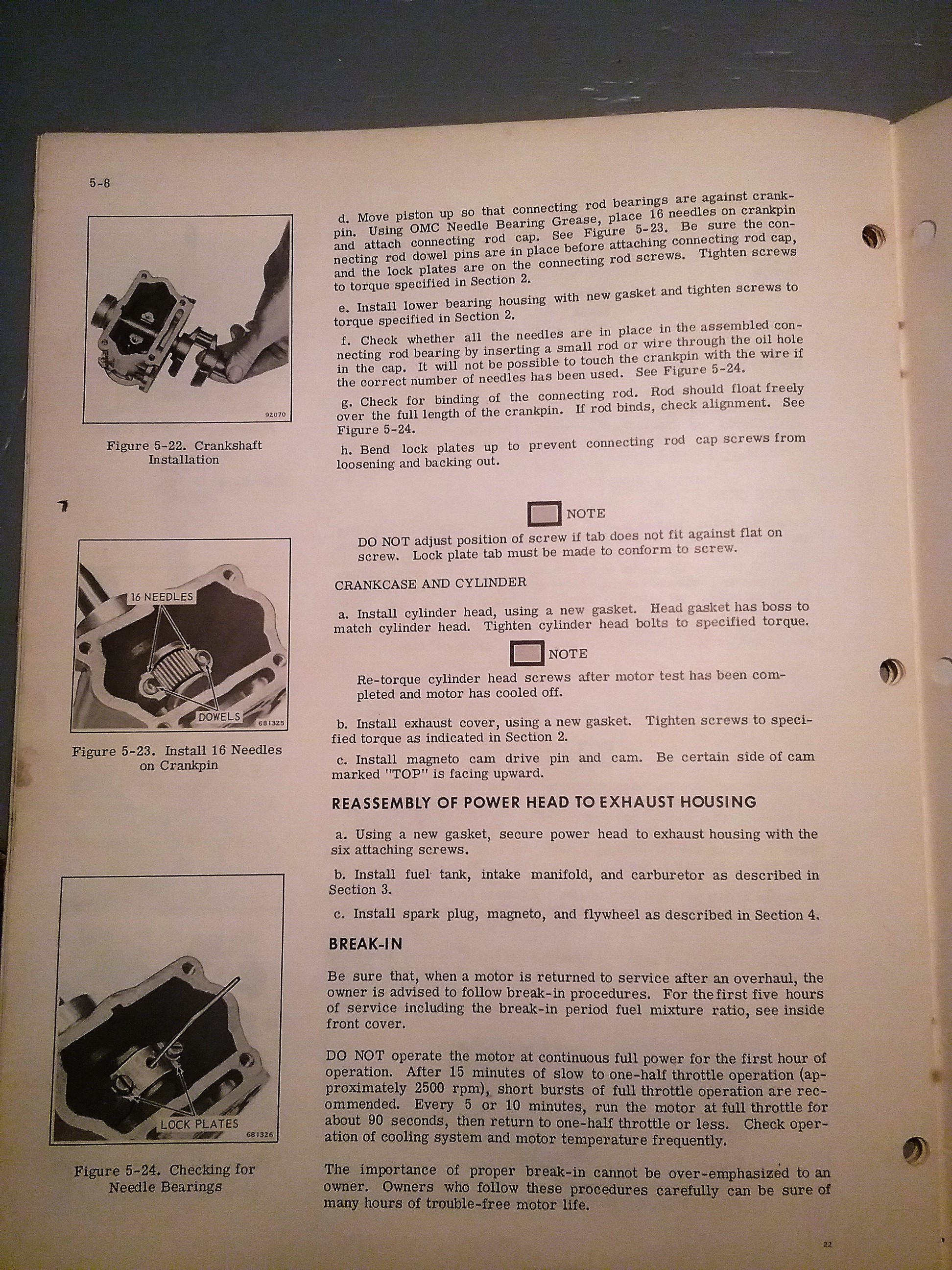

VitoJuly 1, 2017 at 3:14 pm #60743Ouch!! That piston looks like it had a rough day.

July 1, 2017 at 5:36 pm #60761That doesn’t do the cylinder wall any good either . . .

I am always amazed by Mumbles "Don’t let this happen to you" illustrations . . . 😆

-

AuthorPosts

- You must be logged in to reply to this topic.