Home › Forum › Ask A Member › Neptune AA1

- This topic has 24 replies, 5 voices, and was last updated 3 months ago by

RichardMechler.

-

AuthorPosts

-

October 27, 2025 at 5:41 pm #300990

This is fun stuff! Thanks for the replies and the directions to get this little motor up and running.

Is there a way to check the coil on this Neptune AA1? Sorry, I’m a bit electronically challenged but I can learn.

There are ways to test. One quick trick is once you have the whole magneto wired up you can use a multimeter and put one side on ground and the other on the spark plug wire and if you get a reading it might be fine..but if you’re replacing the condensers that should be an easy fix to just test if the coil is good via spark.

"Outboards seem to multiply exponentially..........I find that for every finished project, there are two more waiting to be completed."

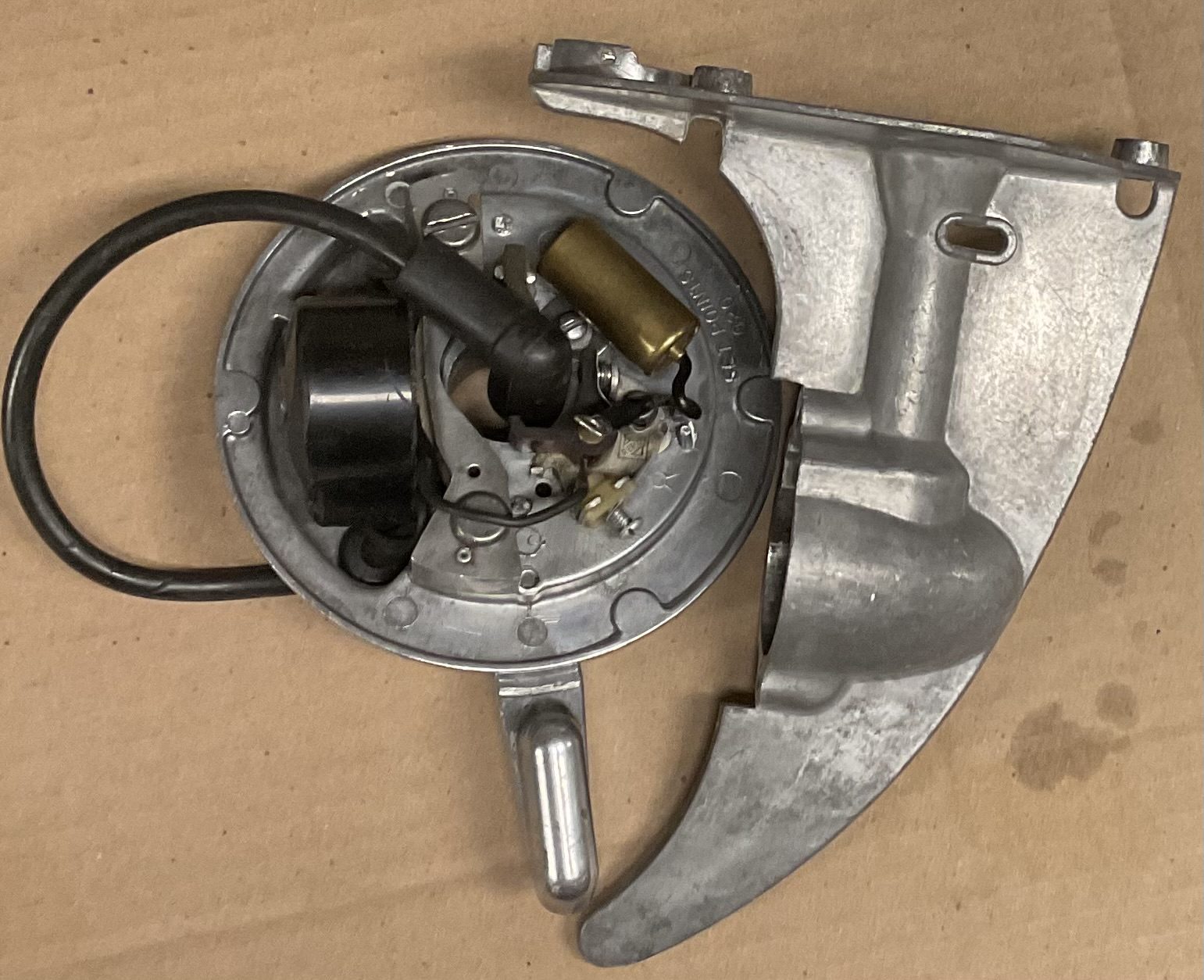

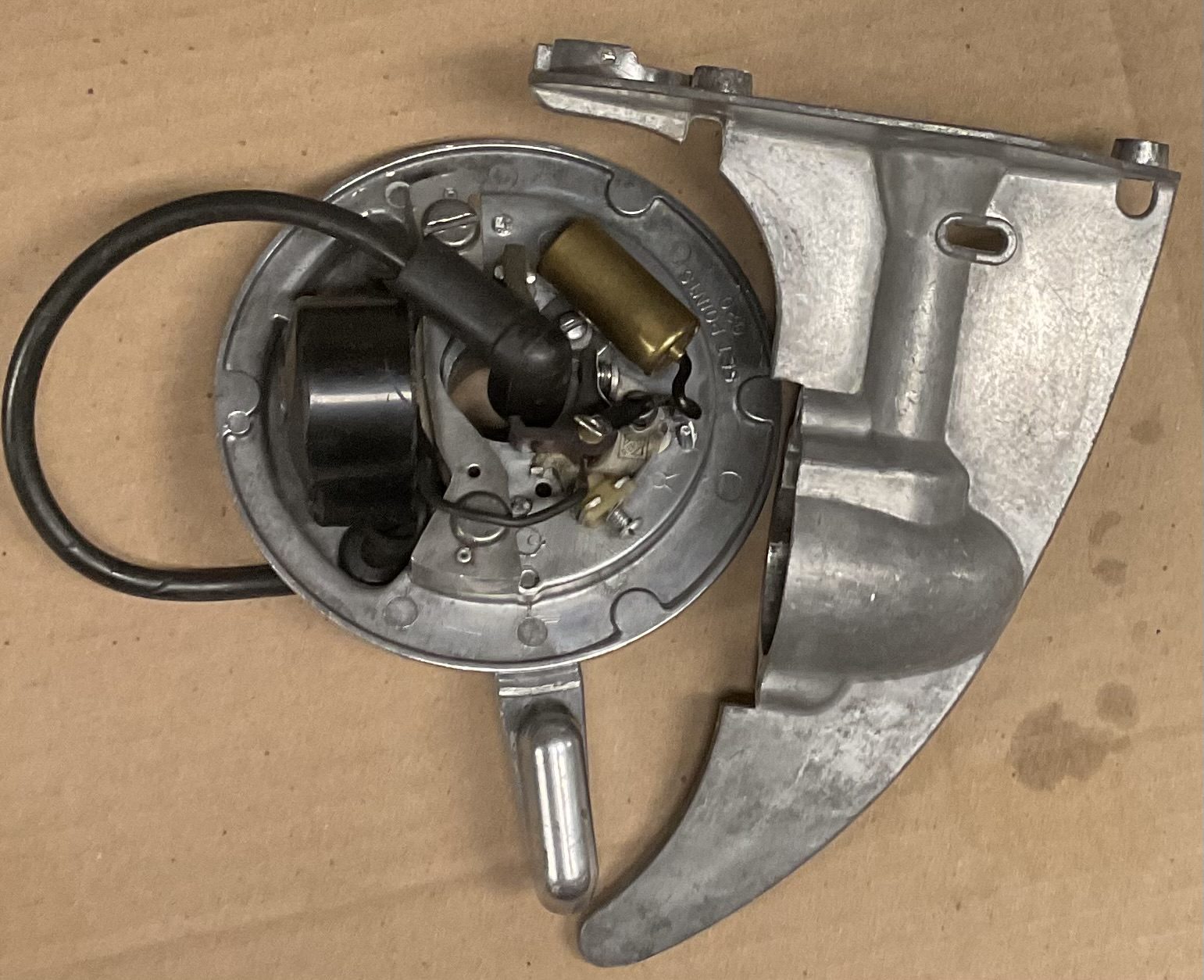

October 27, 2025 at 6:57 pm #300991Is there any way that you can take a picture of the magneto plate under the flywheel and post it up here? Seeing what kind of points, condenser and coil setup you have will help others help you. Neptune used, I know of, 3 different manufacturers over the years for there magneto set ups. Depending on what brand you have, people may have parts that you may need. Also take a picture of your broken lower unit. I may have one that you can have. Just pay me to ship it.

October 27, 2025 at 7:03 pm #300995That looks to be the phelon coil. It looks a bit worse for wear, so you may want to start searching for (but not buying) a different coil in case replacing the condensers does not work.

"Outboards seem to multiply exponentially..........I find that for every finished project, there are two more waiting to be completed."

1 user thanked author for this post.

October 27, 2025 at 8:53 pm #300998I have a good magneto with new parts and a good lower housing. You can have them if you just pay shipping. I will never use them. I would have to take to post office and see how much shipping and insurance would be. I will need your contact information. Text me at two zero one- 3 nine zero- 3 five 1 nine.

1 user thanked author for this post.

October 28, 2025 at 5:57 am #301005I have a good magneto with new parts and a good lower housing. You can have them if you just pay shipping. I will never use them. I would have to take to post office and see how much shipping and insurance would be. I will need your contact information. Text me at two zero one- 3 nine zero- 3 five 1 nine.

November 2, 2025 at 9:25 am #301145We have spark! Thanks Gary! Much appreciated!

November 6, 2025 at 9:01 am #301271Getting close..

Gears in gearbox are worn, but I think they might work for a while. Made some new gaskets, packed with John Deere Corn Head grease, and reassembled without prop in place so we get good water suction during first run? Fuel tank soaking in White Vinegar and we’ll throw some small rocks in the mix and shake them around for a good cleaning. Then we take a quick look at carb and passages, then start cranking. I think we need a different prop!

November 6, 2025 at 10:50 am #301276Having trouble removing the carb float. Removed the float bowl cover and pulled on the inlet valve, but something is not letting the float lift out. Removed the plug at the bottom and I can see the inlet valve rod moving back and forth. Any help?

November 6, 2025 at 11:22 am #301277Can you please provide pictures of this float stuck in place? It will help us give you more specific suggestions. Not sure what you mean by the “valve”. In general though, most floats are held in by a pin or a screw that they rotate on which would need to be removed in order to get the float out.

November 6, 2025 at 5:46 pm #301281The pin that runs through the center of the float is called an Inlet Valve (#122 in schematic).

-

AuthorPosts

- You must be logged in to reply to this topic.