Home › Forum › Ask A Member › Not a Kiekhefer so what can it be?

- This topic has 27 replies, 13 voices, and was last updated 7 years, 12 months ago by

green-thumbs.

-

AuthorPosts

-

February 6, 2018 at 3:30 am #70705

Some very good news to share. Mercury K4 it is. Some more of the parts were dug up including the rope plate stamped K4. Also the original Eisemann 72H magneto and flywheel.

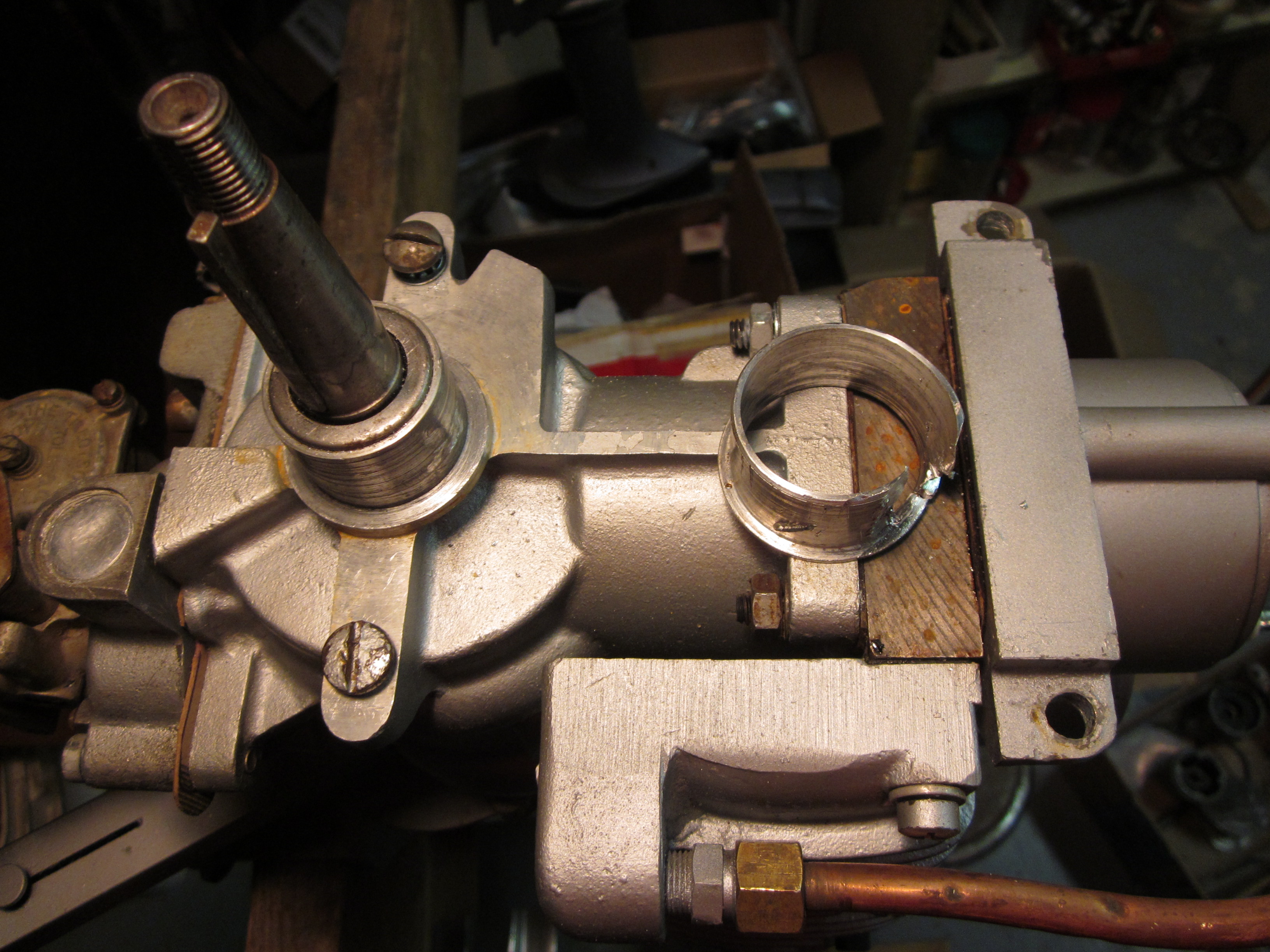

Apparently the 1940 twins has a small mounting snout originally and the Eisemann 72H had a

small center hole for mounting that year. 1941 twins has a stouter snout and the Eisemann 72H

in 1941 had a larger central mounting hole.

In the mean time a skilled machinist Joe B had made and fitted a sleeve. Now that the original magneto was on hand the sleeve was not needed. So some time was spent removing

the sleeve and fitting the original magneto. That led to discovery that the unique cast

aluminum handle that synchronizes spark advance and carburetor butterfly rub. Bent?

I am going to workPlease bear with me on duplicate photos. I am new to posting photos

Removing photos seems a little tricky for me at present.

LouisFebruary 6, 2018 at 10:27 am #70708What an exciting find, to get the K4 sheave! Too bad about having to lose that nice bushing,though.

What does the handle rub on? Is that the gas tank in the background? It would normally have a steel tank, wouldn’t it?

Long live American manufacturing!

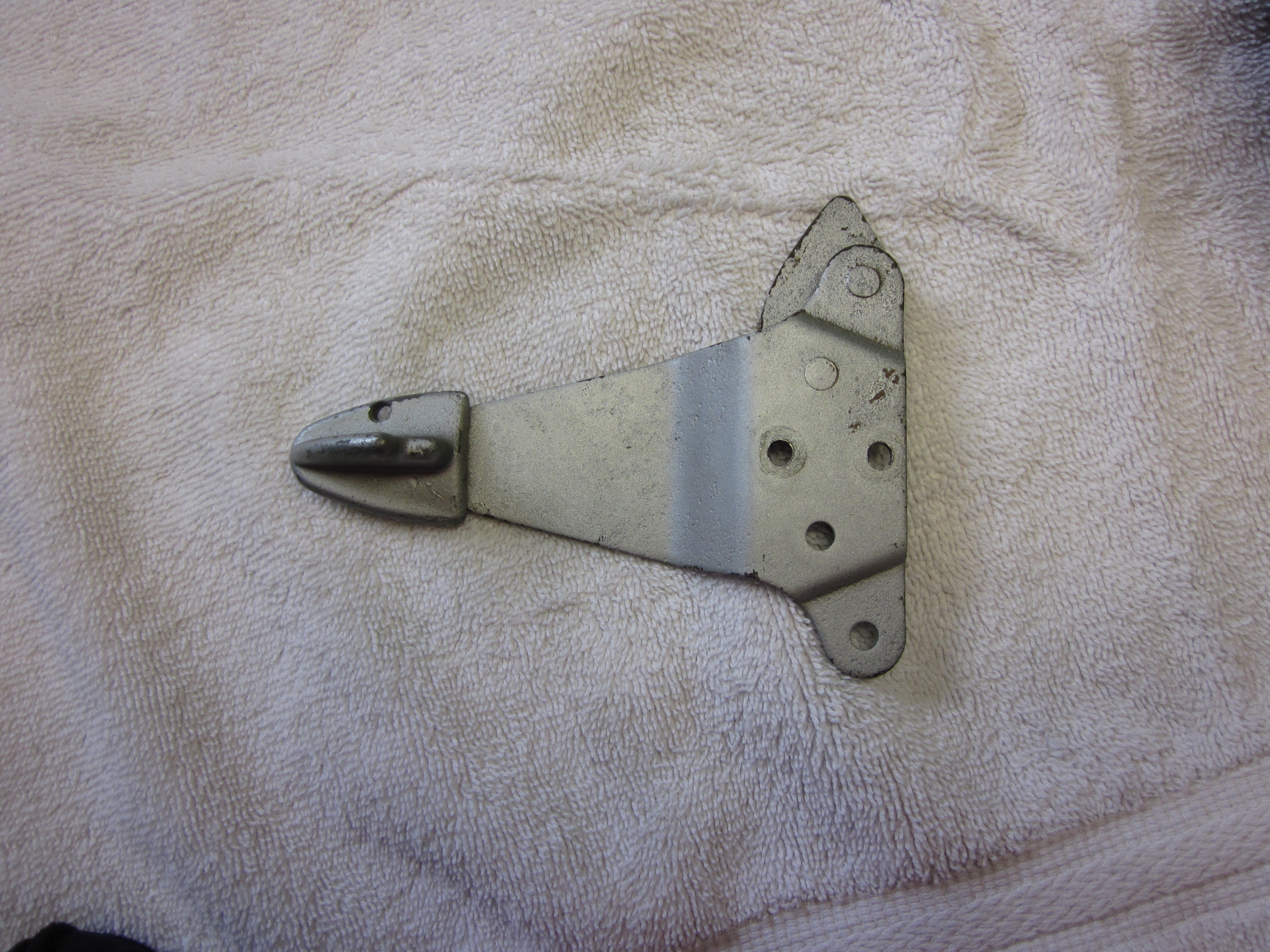

February 6, 2018 at 5:20 pm #70722Of the several missing items needed to reconstruct, an authentic, limited production steel tank would have been the most unlikely to turn up. If and when the that should happen, it could be installed with no difficulty. It may even be that some K4 originally had a cast aluminum tank. Adapting a cast aluminum tank involved drilling two holes in the mounting bracket of the aluminum tank to match the mounting holes in crankcase. The two original

brackets are on hand if needed.

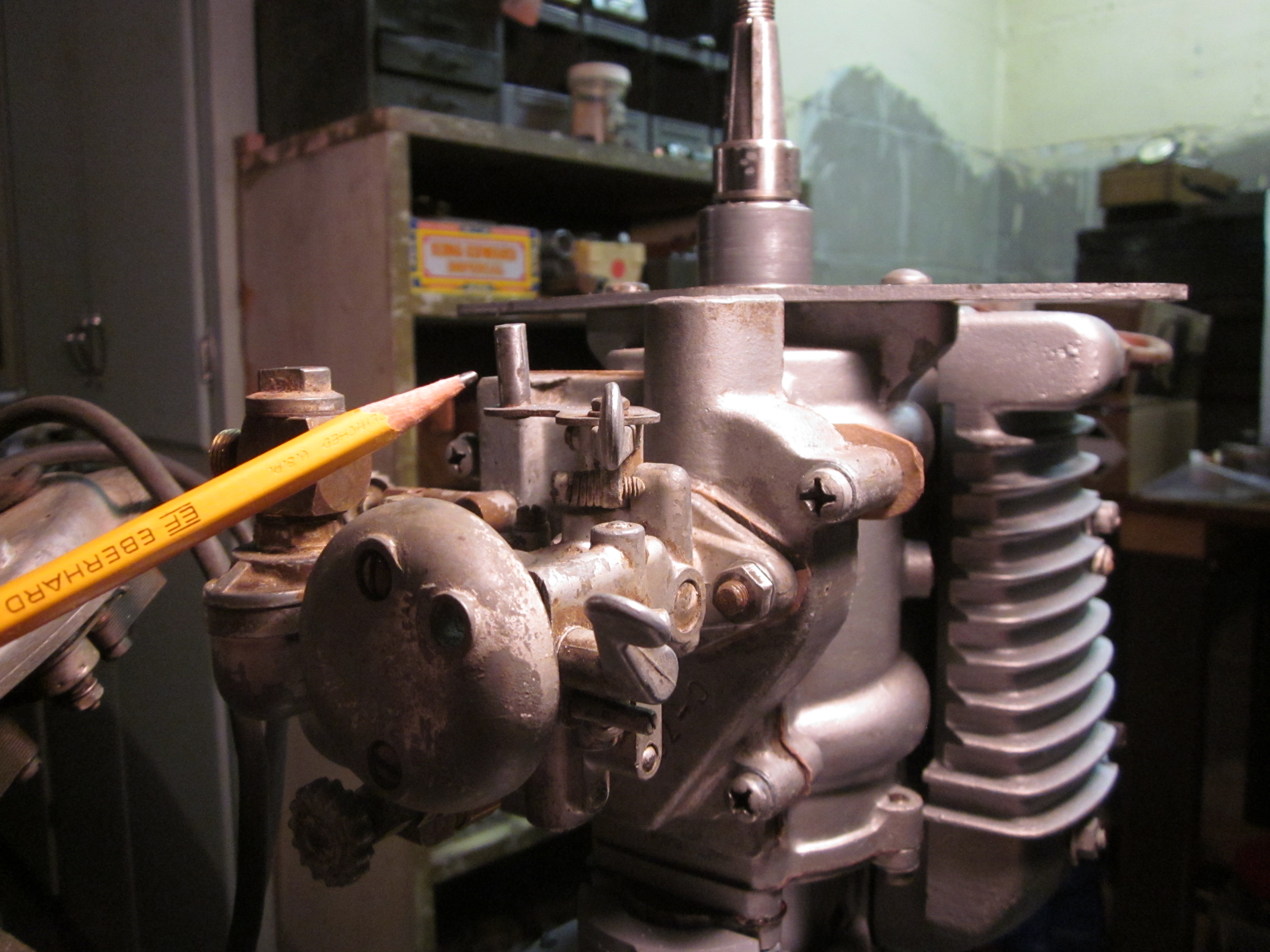

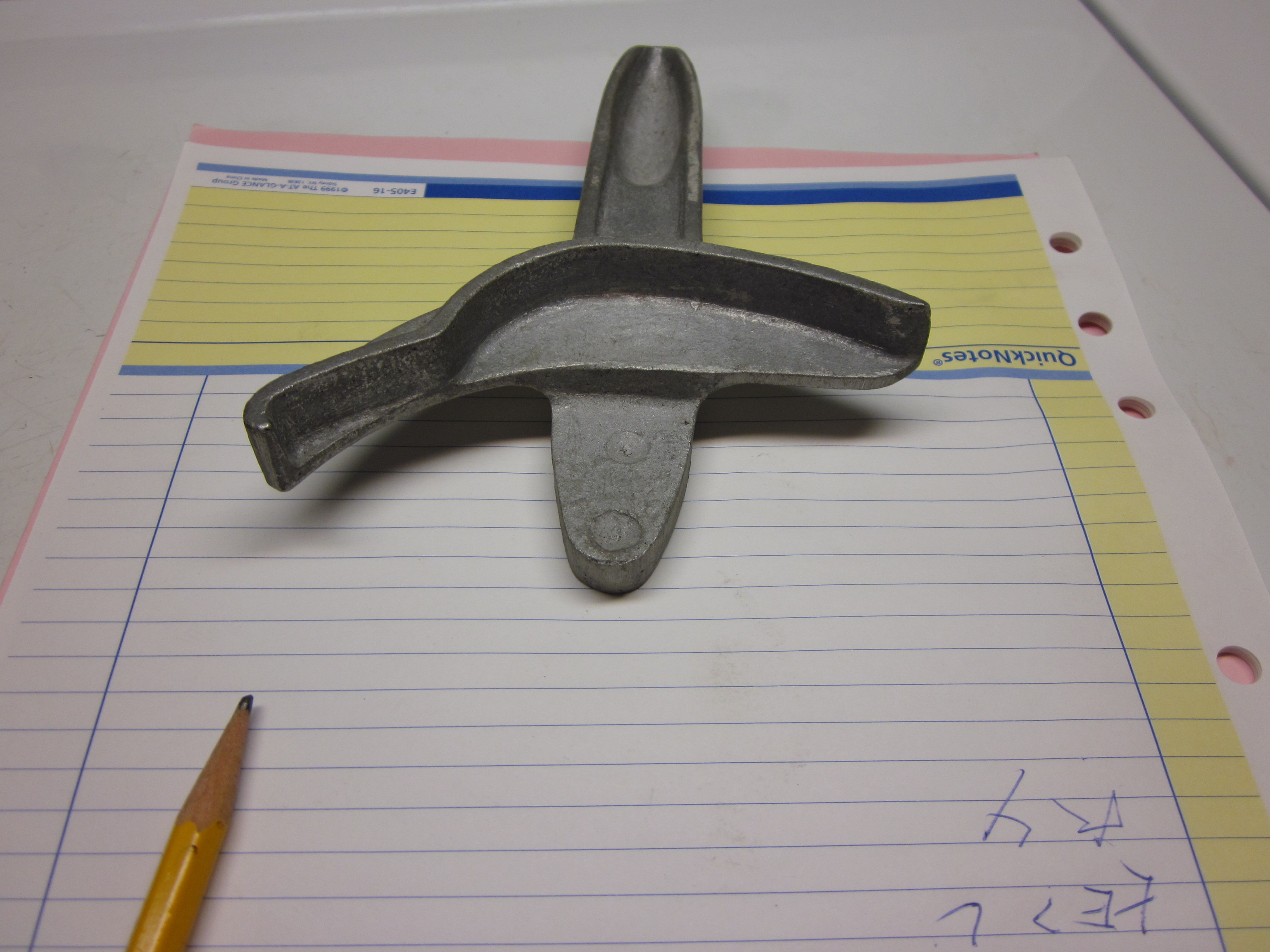

The 1940 Kiekhaefer twins were not a refined concepts. The cast aluminum magneto lever had a cam underside to engage the extension of carburetor butterfly shaft so as the spark was advanced or retarded the carburetor butterfly opened or closed. Com;lex, expensive and damage prone. 1941 evolved to a steel magneto handle/steel cam attached to underside of the magnet plate. Simple, inexpensive and durable.water jacket

February 6, 2018 at 7:01 pm #70727Eisemann 71H with larger diameter mounting hole and stamped steel handle & cam assembly. this will fit revise 1941 and later twins thru postwar up to change over to Bendix magneto which again involved a revised crankcase casting.

Note: to those, like myself, who are too eager to tear things apart…the collection of stamped steel magneto handles that will need some detective work to find their way back to magneto plates they belong to. Can only be done by comparing to unmolested examples.

LouisFebruary 6, 2018 at 7:07 pm #70728February 13, 2018 at 12:37 am #70953A useful hint for those who may be working on a 1940 Kiekhaefer twin.

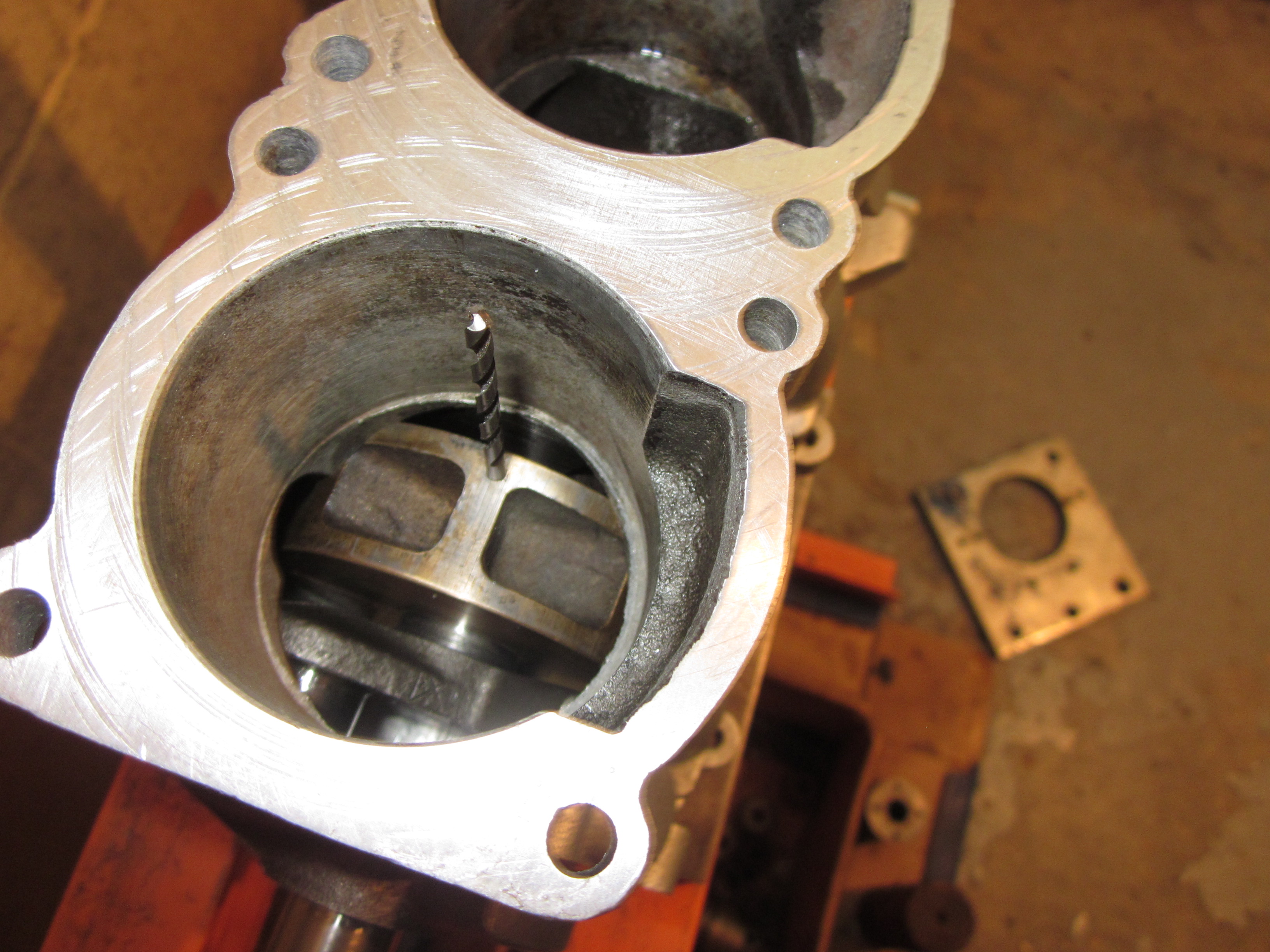

If the drill is straight up and down the holes in bearing block will align with the appropriate

holes in crankcase. The hole also serves to help locate bearing block fore and aft correctly.I was curious about what purpose the hole served when considering how to install bearing block.

A Duh moment.

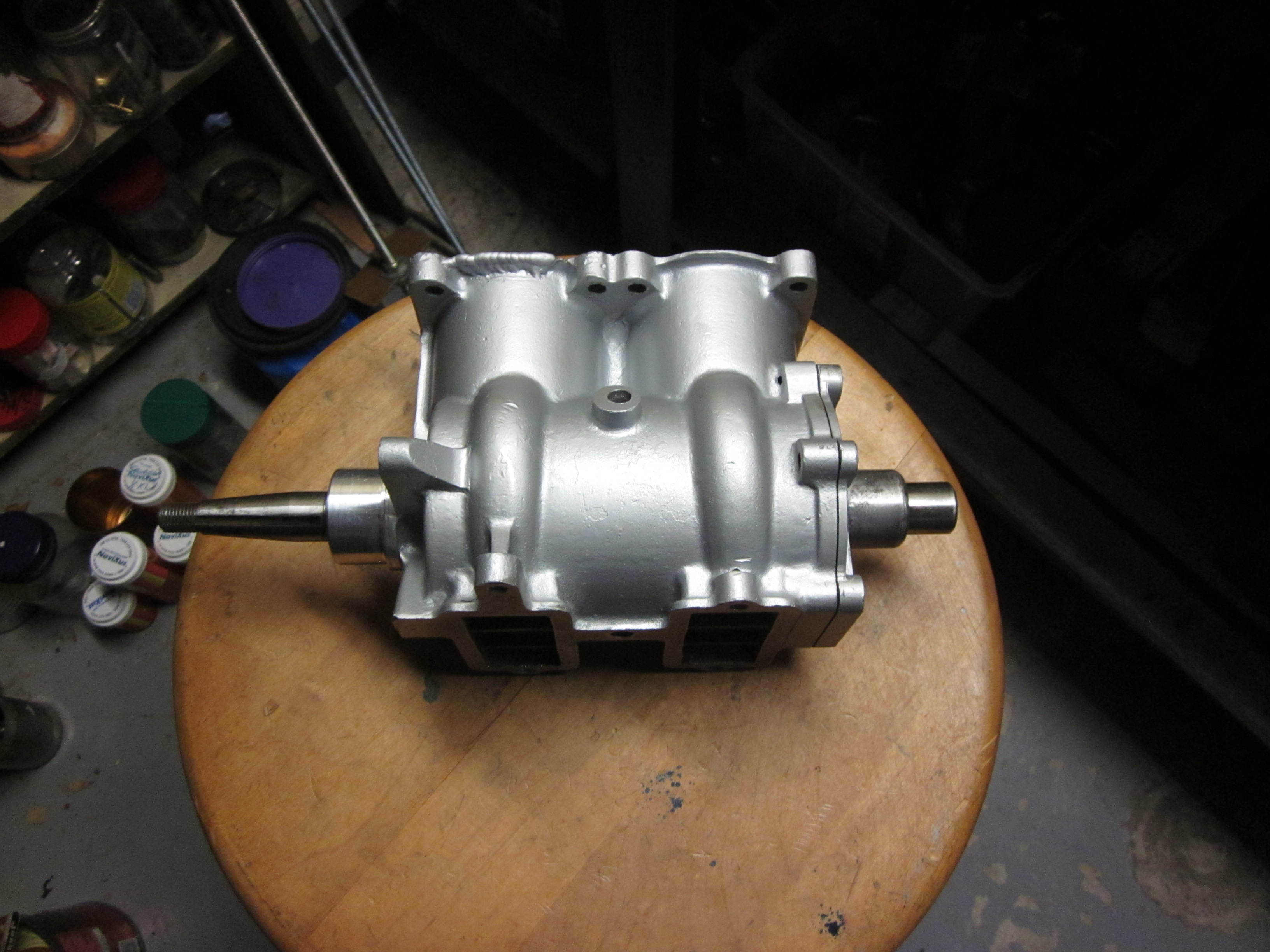

=-February 14, 2018 at 7:03 pm #71055Adapting a later cast aluminum tank to a 1940 twin was not quite straight forward, but, not

that hard. Note the mounting holes are drilled oversize to allow a little slop…part of fit and try

The tank bracket had to be fitted to tank first then the magneto plate installed…no way to

fasten screws with magneto in place.The 1940 twins used 2 short piece tank bracket. which were too short to reach tank mounting

studs. Later tank brackets are one piece.

Back fitting the later bracket did not require any alteration to crankcase. All fastener

holes were over sized so tank could be dropped in place without forcing. Ears on upper

water jacket are often found to be damaged by rough handling so best to be as gentle

as possible.

LouisFebruary 22, 2018 at 12:49 am #71438Kiekhaefer’s Early K Model outboards had 3 separate and distinct water pumps. Each of which could be interchanged as a complete assembly on any of the Early Kiekhaefer outboards

thru KE3 and Wizard WG4. Although the pumps do have some parts in common, they differ in many details large and small.

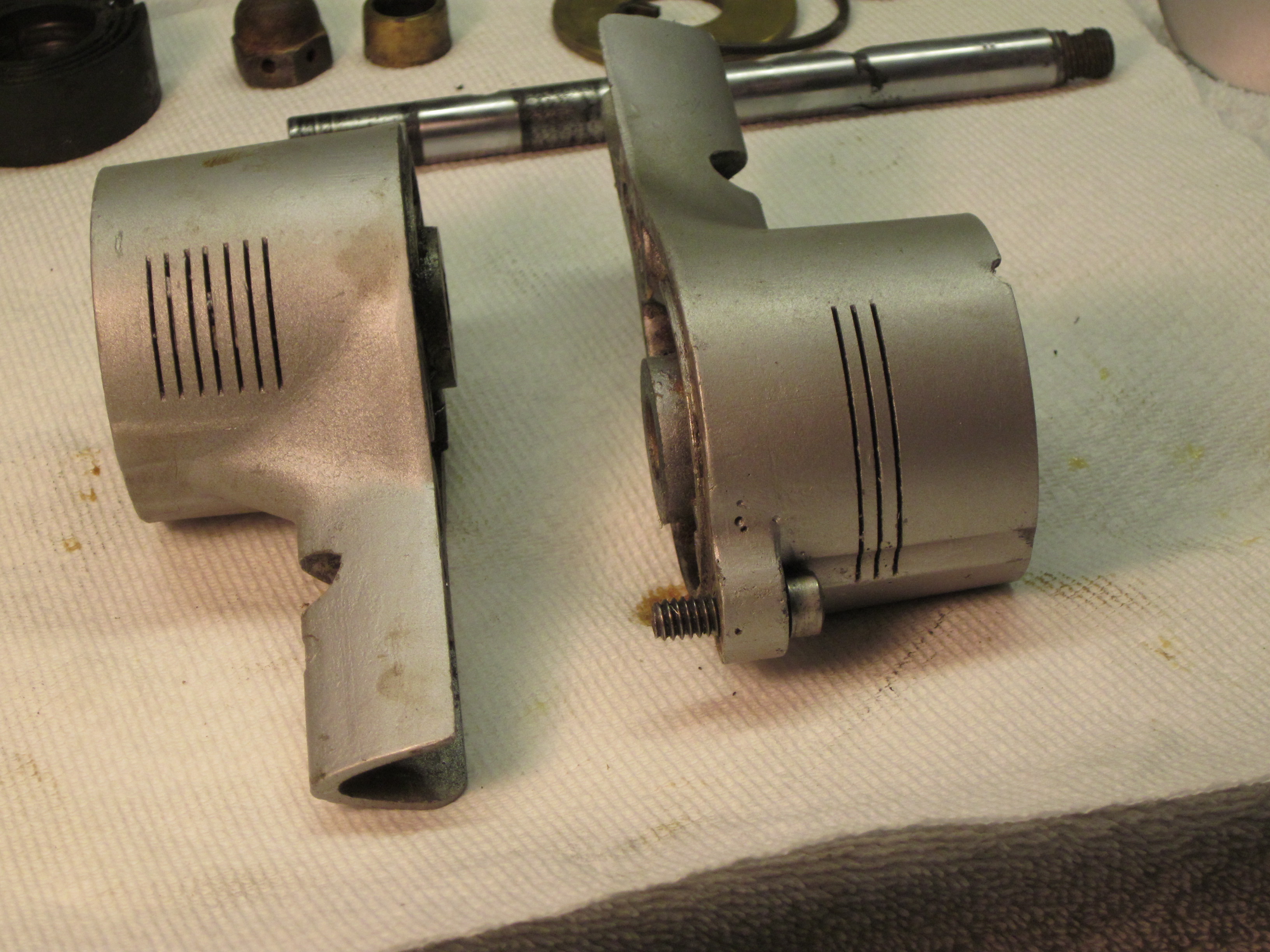

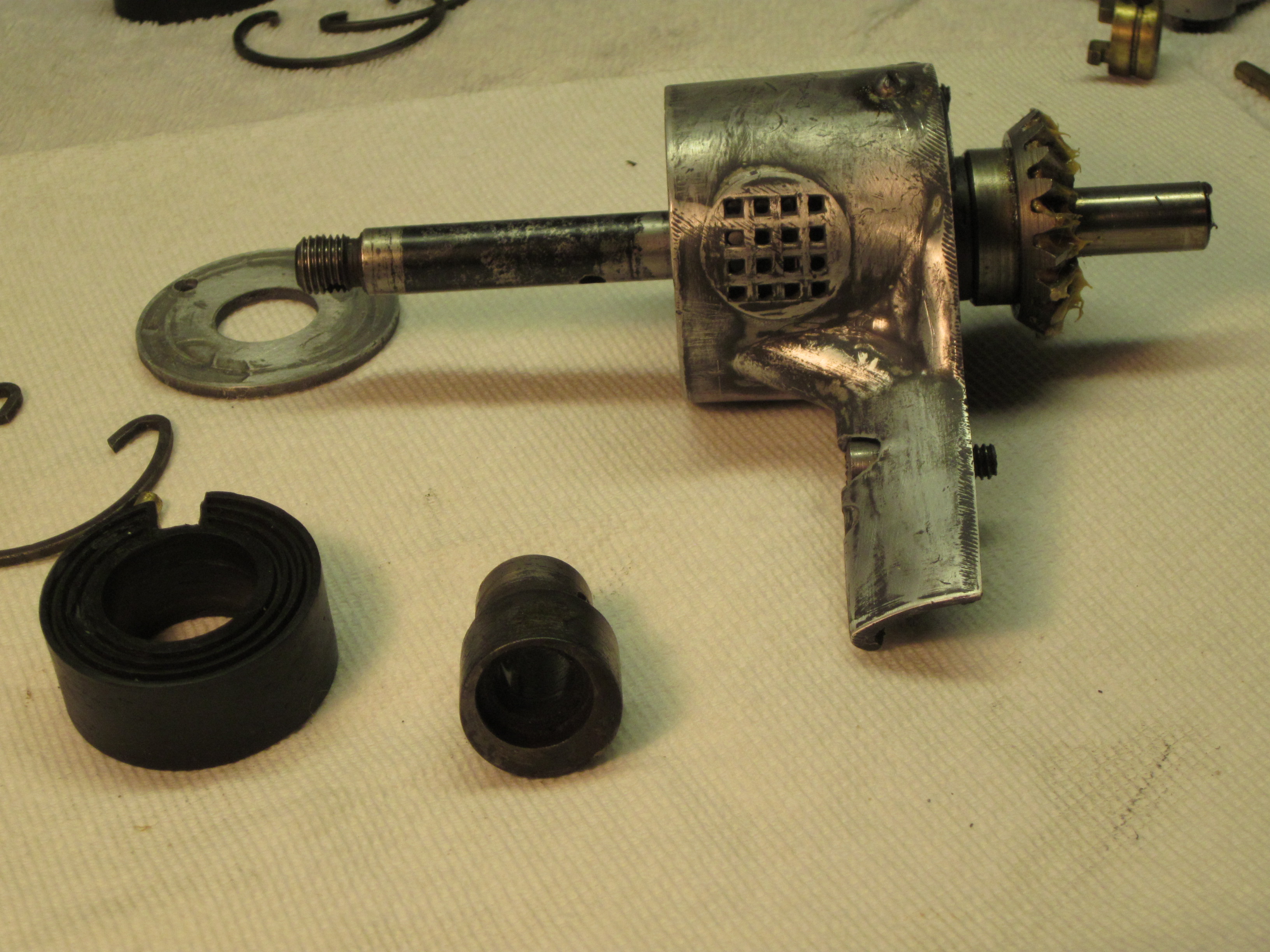

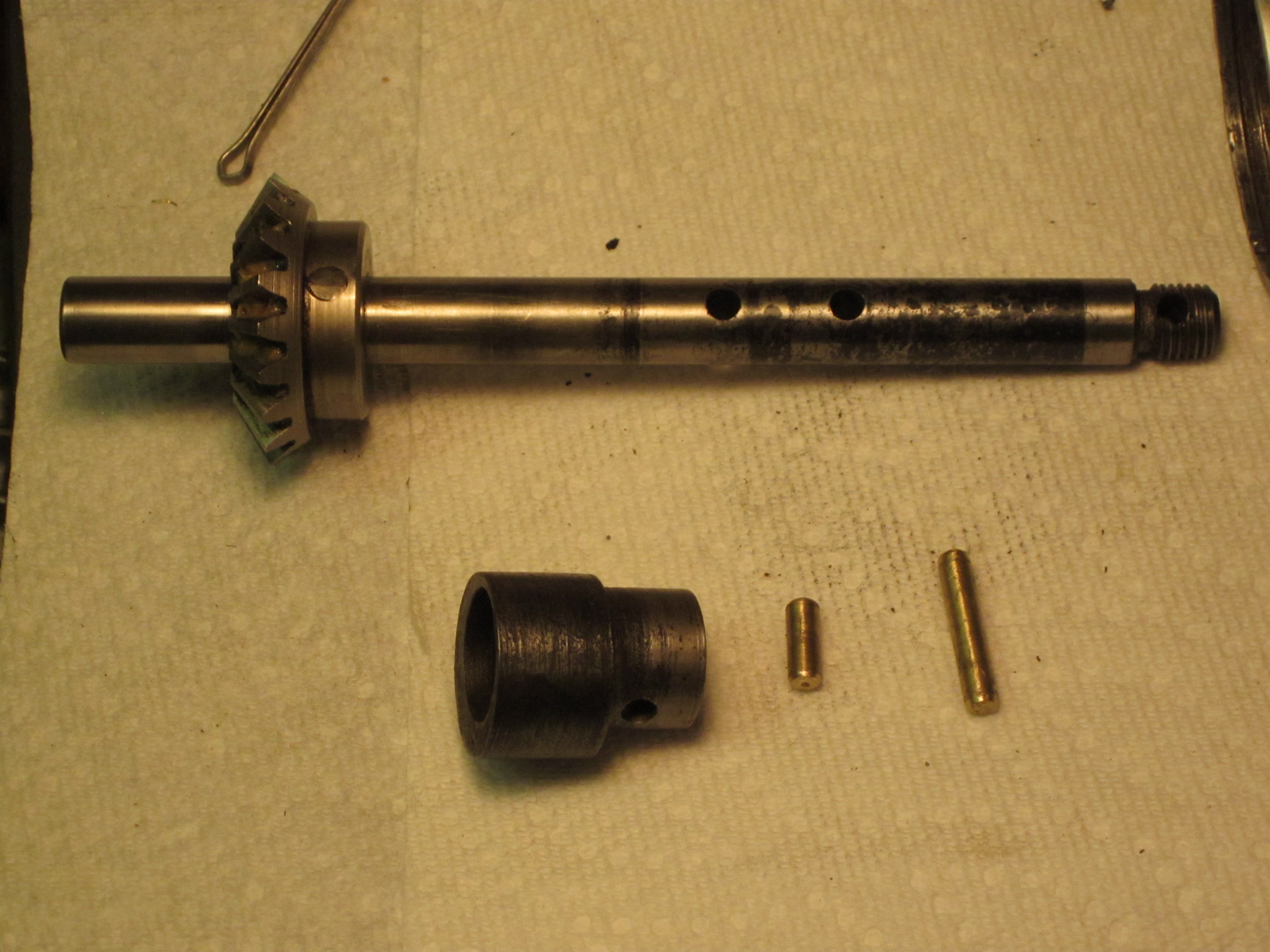

A few photos of Type 1 (16 square hole) oscillator , Type 2 (7 slit) oscillator and Type 3 (3 slit) vane pumps.

Made photos while considering making a short pin required with 1940 version that goes within the cast iron eccentric. A separate shear pin engages notch in hub of Type 1 Propeller

Type 2 water pump has a brass eccentric and is somewhat different in other respects.The 16 square hole 1940 pattern water pump has a cast iron eccentric with a slot that requires a pin short enough to engage the slot but not the holes in eccentric which allows the eccentric

to move up or down the shaft. This is needed to allow the gear to bear on the bearing on gear case side of water pump. The short pin is often misplaced ,but, making a new one is just a matter of fit and try…which is what I was doing when making the photos. -

AuthorPosts

- You must be logged in to reply to this topic.