Home › Forum › Ask A Member › Pal Fuel Leak

- This topic has 0 replies, 1 voice, and was last updated 8 years, 8 months ago by

Tubs.

Tubs.

-

AuthorPosts

-

April 28, 2017 at 1:17 am #6865

fuel

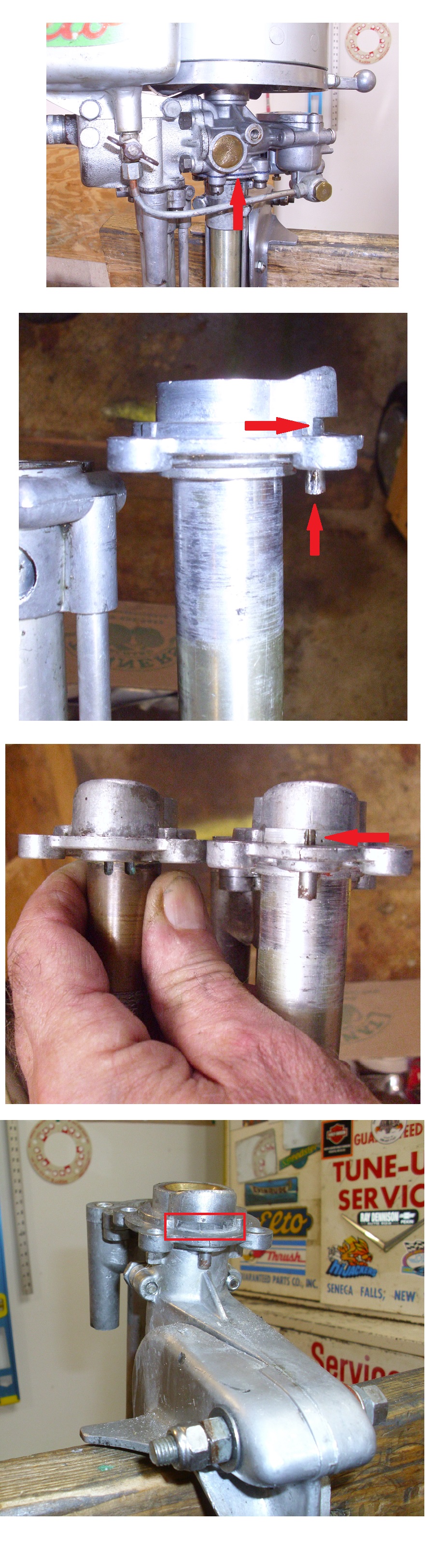

I have a 1937 block and the matching numbers

transom clamp. The block had a rod and

piston without rings but I had a new set. I

also have several cast cylinders so I gave one

a light hone and it cleaned up nicely.

I was able to scrounge up everything else I

needed except the exhaust pipe and a gas tank

although the skag is gone off the gear case. I

have a carburetor but I find that if you have

a banjo fitting that isn’t leaking it best to not

separate the bolt and/or fuel line fitting from

the carb so I cannibalized all that with a gas

tank from another motor. Took awhile to get

it to run at first even without a prop but it finely

did take off and after the rings seated a bit I put

the prop on and it really runs quite well.

https://www.youtube.com/watch?v=3zakS-7_rTgI did notice fuel dripping from the stop

pin. About a drop every 15 or 20 seconds.

That’s probably close to what its burning when

its running slow. I thought the lower bearing

flange gasket was leaking but after 3 attempts

to seal it I began to look a little closer and

decided that the leak was around the pin. As I’m

taking the motor apart for the forth time I’m think

how is this possible as the pin is cast into the

flange. Now that I’m looking I can see where the

flange was machined down to the pin and that

explains the leak but we’ll likely never know why.

Its common to find that the flange has become

loose or separated from the lower main bearing.

I find that about 1 out of every 3 motors will

have this problem. It doesn’t affect how the

motor runs but there is a constant ooze of fuel

from them when they are loose. As this one is

tight and all the others I have are loose I needed

to seal this one which I did with some JB Weld.

Since I have all this stuff out and its a lousy day

I thought it a good time to explained how this

flange becomes loose so those who run these

regularly can avoid this damage as there is no

repair and its a common problem making a good

replacement hard to come by.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.