Home › Forum › Ask A Member › Points woes

- This topic has 13 replies, 9 voices, and was last updated 3 years, 9 months ago by

aquasonic.

-

AuthorPosts

-

March 21, 2022 at 7:29 pm #256604

Hello all, long time lurker, first time poster.

Slightly perplexed here working on a 1958 Evinrude Fastwin 18HP. In the process of getting this beauty running again, I got a pair of points P/N: 580148 which I believe to be BRP points. Completely surprised to discover that the pad would not make contact with the cam on the crank regardless of the eccentric adjustment. Fast forward to points set #2, I purchased. Sierra kit P/N: 18-5006, and wouldn’t you know it, the points base will not fit on the armature plate, the tab for the points spring is to wide and hits the coil. Am I missing something here?

Attached is the Sierra points base.

-

This topic was modified 3 years, 10 months ago by

Mumbles.

Mumbles.

March 21, 2022 at 8:25 pm #256609Search the threads. There’s been a lot of complaints about point sets

now that none are made in the US.Prepare to be boarded!

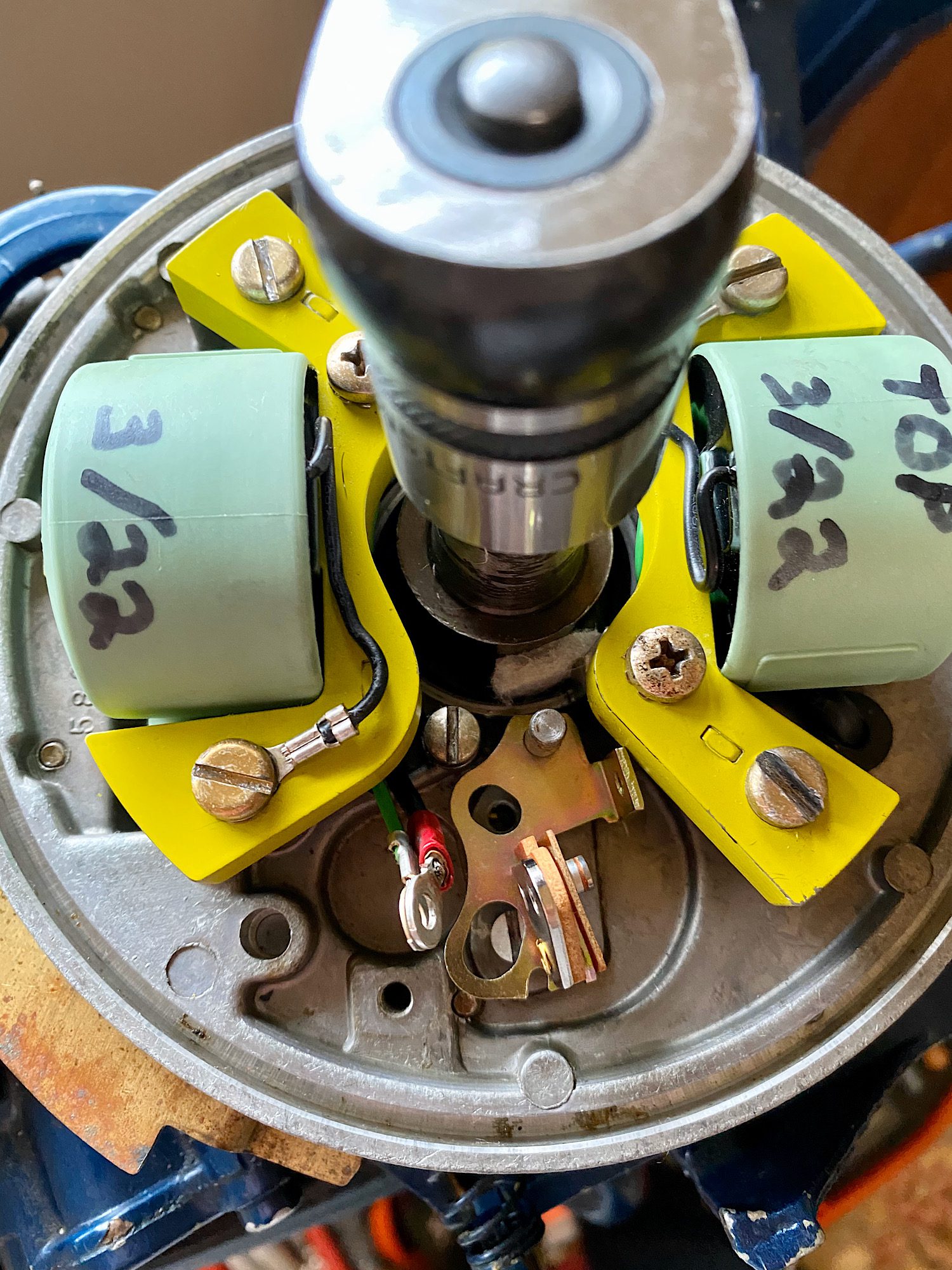

March 21, 2022 at 8:59 pm #256612those coils marked 3-22 seem to take up a lot of room .. are you certain these coils are for the OMC mag plate .

what coil # are they ? recent purchases ?? … what about the old coils can you compare shapes. (spread)

if not the coils can you post side by side and overlapping pictures of your new points and old ones ?

Joining AOMCI has priviledges 🙂

March 21, 2022 at 9:56 pm #256614Thank you for the prompt replies. The coils are new CDI coils P/N: 183-4477 and measure 3.5” tip to tip the same as removed which are what I assume to be OMC/BRP coils labeled 583249 (I believe them to actually be P/N: 0584477).

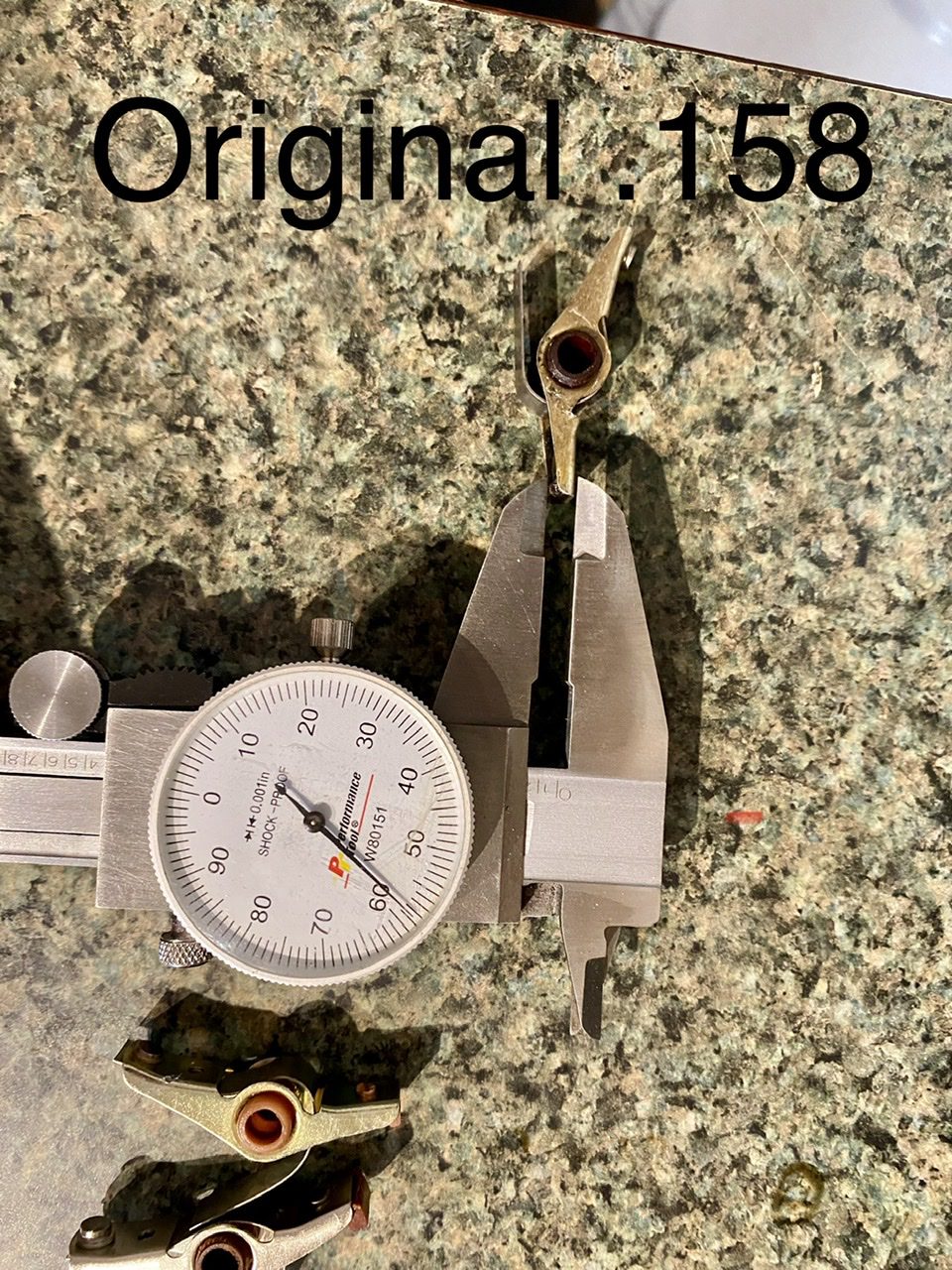

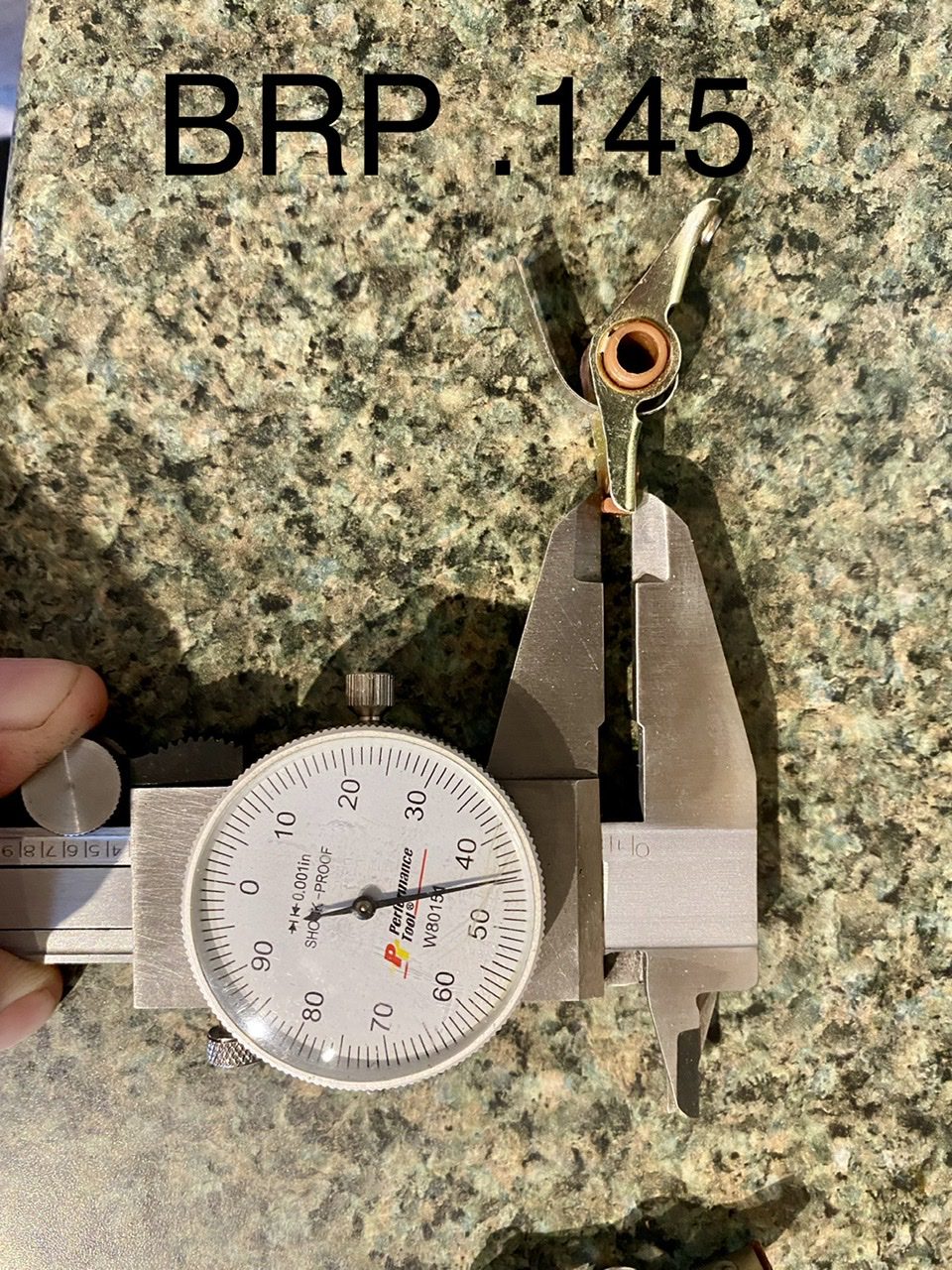

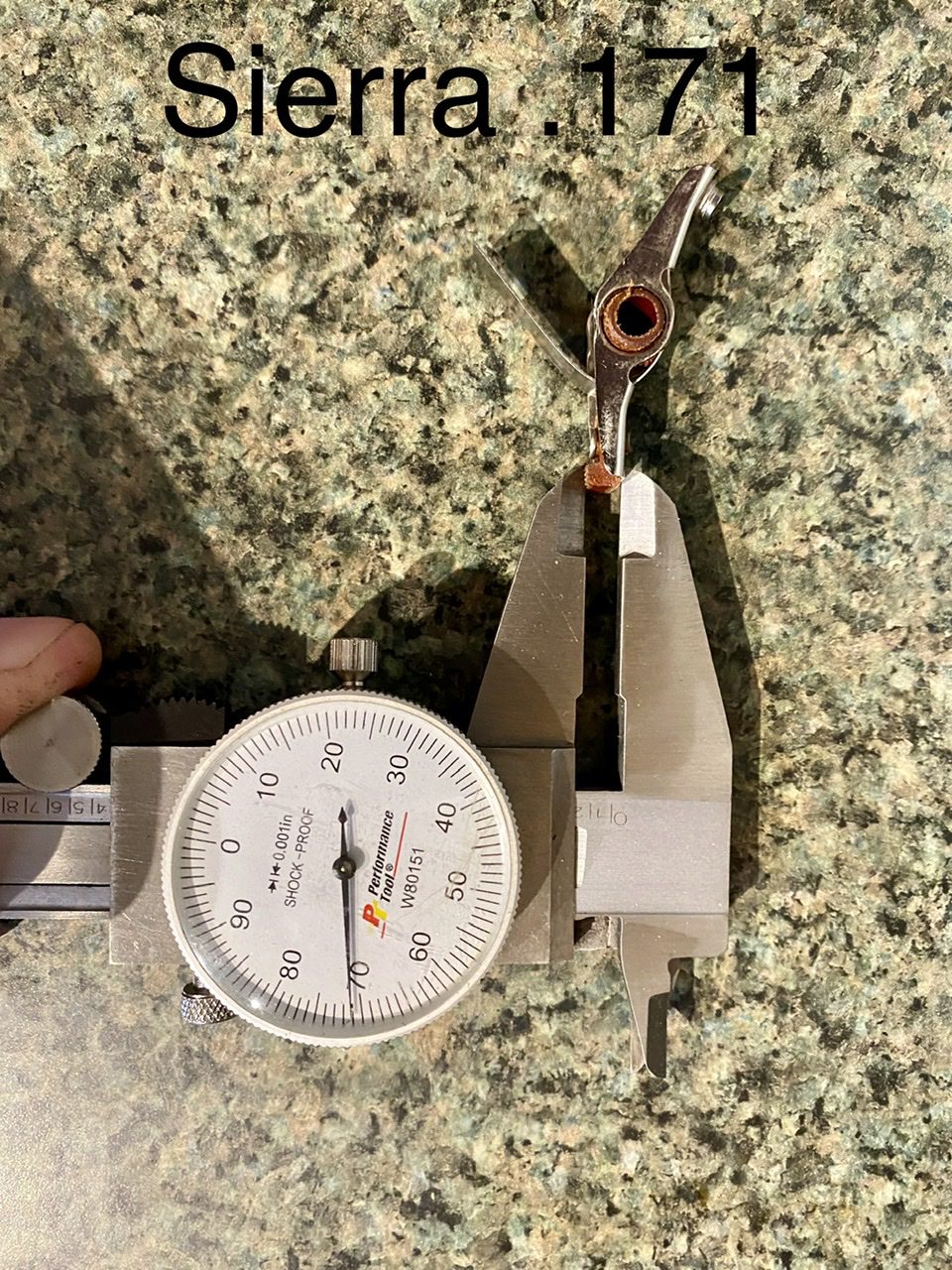

Some measurements from the original, BRP and Sierra points.

Base at spring tab:

Original: .877

BRP: .842

Sierra: .891

Cam block:

Original: .158

BRP: .145

Sierra: .171

The original and BRP points bases fit, the Sierra does not.

The BRP points cam block does not touch the crank cam.

I can get it to work using the BRP base with the Sierra upper points, but I don’t think I should have to buy 4 sets of points to get two good ones.

March 21, 2022 at 10:00 pm #256619March 21, 2022 at 10:26 pm #256624I had a similar problem on my ’57 Fastwin ignition rebuild. I also used the CDI 183-4477 coils with no problem but the rub block on the new BRP 580148 points was shorter than the original points that were in the motor. I don’t recall the measurements I took at the time but when using the new points I could only get a maximum points gap of .018 – see pic enclosed. The older BRP points made in Turkey always worked fine – the newer versions made in Hong Kong are not as good and on my Fastwin project, the BRP points stated Made in USA on the packaging. Too much outsourcing of parts again I guess.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."March 22, 2022 at 1:16 am #256631@Buccaneer I did do a search prior to posting. It appears that the consensus was to enlarge the eccentric hole to allow for more movement. On the BRP points set, even with the eccentric screw completely removed and the points plate pushed all the way over touching the condenser screw boss, I still am only able to get .014 gap.

March 22, 2022 at 7:50 am #256636well they sure measure different hopefully the folks at Sierra can be feed back this info to prove to them they are selling crappy products and if they continue they won’t be selling this line of product much longer to folks in the know……

As to the modification ” the consensus was to enlarge the eccentric hole to allow for more movement.” and then not being able to reach .020 my understanding is that points gap is not criticial as long as the points open at TDC with the VOM method or points timing tool .

http://www.youtube.com/watch?v=ga1Cjymj6ms&feature=youtu.be

Joining AOMCI has priviledges 🙂

March 22, 2022 at 8:23 am #256640I also had to remove the eccentric screw to get the “genuine BRP” points (made in China ) to work. Also had to grind down the spot where the point base hit the condenser casting and finally got them to open to 020″. I’ve got lots of old used point sets which I think I will “recondition”. Probably better than dealing with the junk they’re now producing.

-

This reply was modified 3 years, 10 months ago by

lindy46.

lindy46.

March 22, 2022 at 8:59 am #256643I also had to remove the eccentric screw to get the “genuine BRP” points (made in China ) to work. Also had to grind down the spot where the point base hit the condenser casting and finally got them to open to 020″. I’ve got lots of old used point sets which I think I will “recondition”. Probably better than dealing with the junk they’re now producing.

-

This reply was modified 3 years, 10 months ago by

lindy46.

lindy46.

Pretty much sums it up. Gotta do what you gotta do.

-

This topic was modified 3 years, 10 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.