Home › Forum › Ask A Member › Power Head Cross Reference for 1958 Evinrude Fisherman 5516

- This topic has 59 replies, 15 voices, and was last updated 3 years, 8 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

March 29, 2022 at 11:17 am #257116

Questions answered. Will address the first couple and then dive in this afternoon to answer the rest to isolate the stiffness.

- Don’t believe the crankcase has been apart. No scratches on the paint.

- Removed the pistons last night. Rings were oiled and moved easily in the grooves. Surprised by the gaps, .002 and .005. Rings are flat, then a lip. Filing these would not be easy.

- Connecting rods caps. Bottom is silver, top on is not. They are oriented in the same direction and I can read the part numbers on them. I have taken photos through out and been careful to mark as best I can. The bottom cap was very scratchy on the part that faces the journal.

- I placed the crankshaft in the case and spun it, no top half. There is no wobble, the crankshaft does not appear to be bent.

- Reassemble the crankshaft in to case and lightly tighten the screws. The attached youtube video attached.

- This afternoon I will reassemble with the pistons to try and isolate where the stiffness is coming from.

- https://youtu.be/jhQ1LlPwj0A

- Sorry if this post is not flowing smoothly. I am having many problems loading the photos and replies taking place.

March 30, 2022 at 12:04 pm #257143Completed the videos that will hopefully provide the cause of the stiffness. There are 5 videos.

Crankshaft in the case with no cover.

Crankshaft in case with cover no pistons

1958 Evinrude Fisherman 5.5hp Just Pistons

Pistons connected to crankshaft no cover

Both Covers on pistons in place

The crankshaft seems to me to be true and not bent.

My feeling is that the bushings on the connecting rods are rough and provide a significant amount of resistance to turning the crankshaft. Since I would replace both connecting rods it didn’t make sense to do one at a time. This is difficult for me to assess since I have not this type of testing with an outboard motor on the bench. There is no oil lubricating anything except for the WD-40 in the cylinders.

March 30, 2022 at 12:04 pm #257142Completed the videos that will hopefully provide the cause of the stiffness. There are 5 videos.

Crankshaft in the case with no cover.

Crankshaft in case with cover no pistons

1958 Evinrude Fisherman 5.5hp Just Pistons

Pistons connected to crankshaft no cover

Both Covers on pistons in place

The crankshaft seems to me to be true and not bent.

My feeling is that the bushings on the connecting rods are rough and provide a significant amount of resistance to turning the crankshaft. Since I would replace both connecting rods it didn’t make sense to do one at a time. This is difficult for me to assess since I have not this type of testing with an outboard motor on the bench. There is no oil lubricating anything except for the WD-40 in the cylinders.

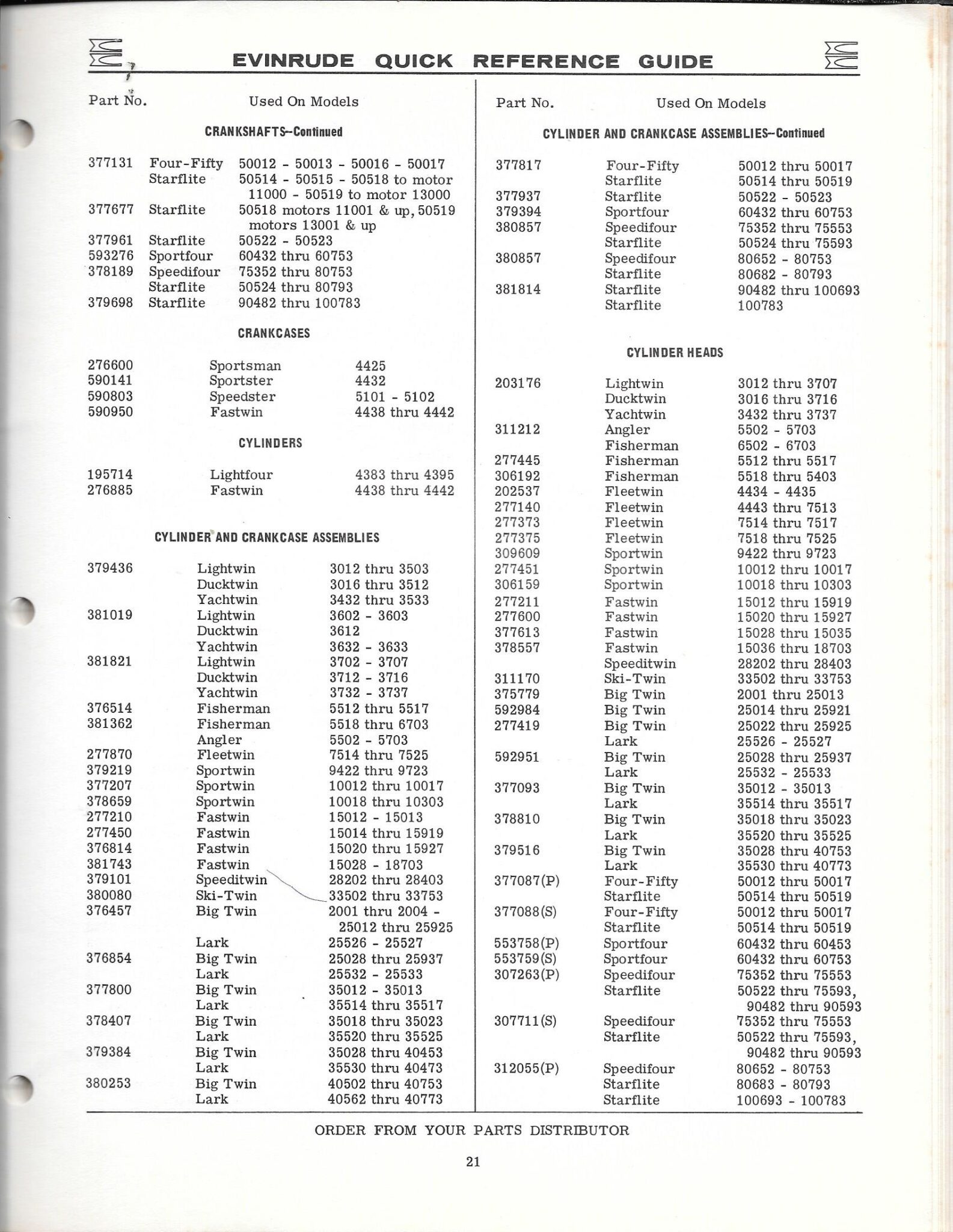

March 30, 2022 at 4:24 pm #257187Thought this might be appropriate for this thread.

1 user thanked author for this post.

March 30, 2022 at 5:07 pm #257190OK, well first I want to warn you about not using any abrasive on those crankcase faces, even fine grit…Be very very careful, taking off any meat on either side will cause the crankshaft to bind. Next, I will go on to say that the crank seems to rotate freely even with the crankcase halves snugged up, so I would agree that the crank does not appear bent. Next, I want to ask you why those taper pins seem to be in place when you are rotating the crank without the halves assembled? Next, I wanted to ask about the videos of rotating with both pistons/rods connected, were the rings in place?? If so, it doesn’t appear that there is too much rolling friction. If there were no rings installed, then perhaps there was too much rolling resistance.

Next, I want to question the color of the paint on the powerhead. I saw a picture/video and the blue seemed too bright, but I can’t find that picture/video now. Perhaps this is just due to video/picture quality, who knows. Is this engine new to you? If so, did you every have it running? Was the powerhead stiff when you got it? Or, did it get stiff after you ran it? Again, forgive me if I forgot the details of some of your older videos/pictures, but were you rotating the powerhead with the gearcase connected? If so, perhaps it is the gearcase that is stiff, or perhaps the new impeller is stiff.

You mention something about the part numbers of the rods being visible, but that doesn’t mean the caps are connected to the proper rod, or oriented properly on the correct rod. While it surely is possible that a messed up rod bearing could certainly cause the engine to be hard to rotate, I just want you to be sure everything is OK before reassembling. Once the new rods arrive, you should assemble them to the crank (with caps properly oriented), and rotate them around the crank, there should be little or no resistance. But, I guess before you do that, you should look at each new rod, find the line up marks, and mark them carefully with a permanent marker to ensure the caps stay with the proper rods and the caps stay properly oriented on the rod. I know I keep pounding this point, but it is an easy mistake to make. And it is not too hard to mix up the rod caps, especially when unboxing and pulling them apart. So, I want you to mark each rod carefully before you pull it apart to ensure things don’t get mixed up. And yes, new rods will take care of any rod fit/cap orientation/cap mix up issues. But, I just want to be sure you thoroughly understand what I am referring to before you start to work with the new rods. Nonetheless, I want you to post a picture of at least one old rod with its matching cap assembled showing the line up marks I referred to (don’t assemble the rod to the crank).

At this point, I am not convinced of anything…Starting with whether or not this powerhead has been apart before. Perhaps you can take some more pictures the powerhead and midsection showing the paint. The only thing I feel confident in concluding is that the crank is OK/not bent, and its rolling resistance in the block seems normal.

Again, we are here to ensure you are successful with this project, so please don’t be put off by my continued questioning. I am not there, so can’t see everything you see.

-

This reply was modified 3 years, 9 months ago by

fleetwin.

March 30, 2022 at 5:30 pm #257192Mike, How smooth do the rods spin on the crank without having the pistons in the cylinders? The crank seems to spin very freely with and without the crankcase halves installed. If the rods spin freely on the crank then I would retry without the rings installed and pistons in the cylinders. One thing at a time.

March 30, 2022 at 5:33 pm #257193Also put some 2 stroke oil in the cylinders…don’t want to run them dry…not sure WD40 is enough lube.

March 30, 2022 at 7:19 pm #257208Tonight I removed the pistons and cleaned up all the journals and crankshaft with 400 grit carborundum very carefully.

The attached video shows how the crankcase can be turned without the pistons. I also spun the crankshaft in the case without the top cover. It rotated smoothly with any wobble at all, so I believe the crankshaft is straight.

I removed the top 2 piston rings from each piston to measure the gaps, bottom had ~.002, top had ~.005. The.002 is too little, the .005 is on the bottom end of ok. I was expecting more ring gap. Before the pistons came out I could move them by hand when they were in the crankcase. If had to file the rings there is the gap, a lip and then the rest of the ring. Filing that lip would be difficult to do with my dremel tool and a rotary file. The lip is very thin and just touching it would remove the ring material very quickly. Filing it by hand would be risky as well.

The crankshaft bearing measurements are greater than spec. It was difficult to get measurements with my digital caliper, it was around 20 degrees in the garage. I was careful in polishing the crankshaft journals with the 400 grit. You can see they are not quite polished.

The cylinder walls were smooth top to bottom.

Please advise on where to go from here. Ed Elliott has new connecting rods and all the gaskets needed to put this back together.

Thank you for your patience and time.

-

This reply was modified 3 years, 9 months ago by

AOMCI Webmaster.

AOMCI Webmaster.

-

This reply was modified 3 years, 9 months ago by

Mike Nazarenko.

OK, this video is where I took note of the powerhead color. That blue is too bright to be original paint, but again the video quality may have distorted the color. And yes, you should not have to file the ring ends to get them to fit. Something is wrong if there is no ring end gap. I still think someone was inside this powerhead before…

March 30, 2022 at 10:11 pm #257215Big Day – – thank you for all the feedback.

- Very light rubbing on the crankcase journals. No rubbing on the crankcase faces.

- Using oil on pistons for lubrication.

- Taper pins – – ok – – full disclosure. Used a fine file to remove edges of the pins. Does not affect the pins when the crankcase body halves come together.

- Rings were included when pistons were inserted into the cylinders.

- Paint on the power head. Purchased a new Iphone this week and was unaware until the videos were posted that they would be converted to black & white. I have fixed the settings so the color is true. Some things tell me this power head was not taken apart – – the color of the paint, no scratches, paint on the screws was aligned with the paint on the crankcase. Some things tell me this power head may have been taken apart – – the crank rods are different colors, there are small black washers on the cap rod screws for the top cylinder but not the bottom. The top piston has some carbon and a tiny bit of rust on it, the bottom piston does not.

- Engine is new to me and I have not ever had it running. Power head was stiff when I got it, originally thought it just from sitting.

- Rebuilt the gear case and the drive shaft can be turned in forward, neutral and reverse with hand pressure and a wrench to grab the spline on the drive shaft.

- There is a photo of the connecting rod caps. They are marked (as when I opened the case) and the alignment marks line up.

- This is only my 3rd rebuild and I’m not offended I’m learning from the suggestions.

You Tube Videos:

March 30, 2022 at 10:40 pm #257220Mike, I think you found your problem…I would replace both rods personally, don’t like the looks of either rod movement, someone has been in that engine for sure. The .002 ring end gap is way too small…the .005 is bare minimum. Fleetwin should be able to tell you what a good ring end gap would be.

-

AuthorPosts

- You must be logged in to reply to this topic.