Home › Forum › Ask A Member › Pressure tank rebuild?

- This topic has 7 replies, 4 voices, and was last updated 8 years, 3 months ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

September 30, 2017 at 12:08 pm #8364

What sealants and where do you apply them when rebuilding the OMC pressure tanks? I am abou to do one and was just wondering what you have all found to work well

September 30, 2017 at 12:29 pm #65585A lot of guys say they put their gasket on dry. It can work. However, sometimes you get a failure. Adding gasket sealant to it will not hurt, so I do it for extra security. I also coat the screw threads in 3M 847 before installing them.

Is the tank a metal button or plastic? That will determine how I seal the diaphragm.

Make sure you shake the filter assembly before installing it, to ensure the check valve is not stuck. You should hear it rattling around.

September 30, 2017 at 1:46 pm #65593Thanks Chris,

It’s the metal primer button.September 30, 2017 at 2:18 pm #65596Ok then be sure to seal the hole where the shaft runs through the diaphragm as well before installing washers.

September 30, 2017 at 2:48 pm #65600The metal button should turn freely on the shaft. . . 😉

September 30, 2017 at 7:26 pm #65608

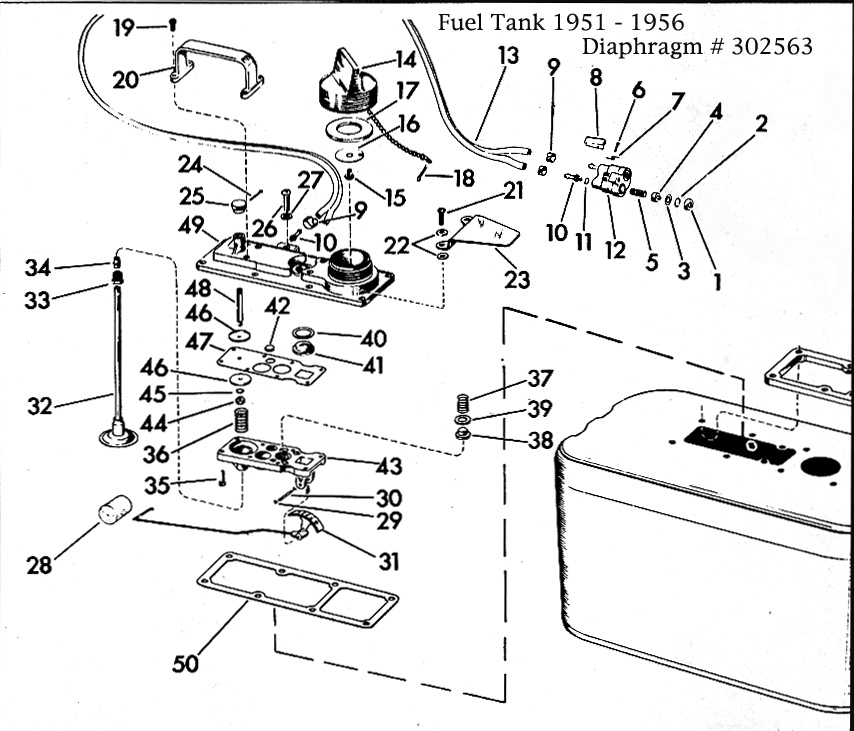

September 30, 2017 at 7:26 pm #65608I think Frank made the second picture up but I add 3M 847 between the washers #46 and diaphragm #47 to ensure the primer button doesn’t leak fuel. This was one of the reasons they swapped out to the plastic button. There was no hole/bar in the diaphragm on them to leak.

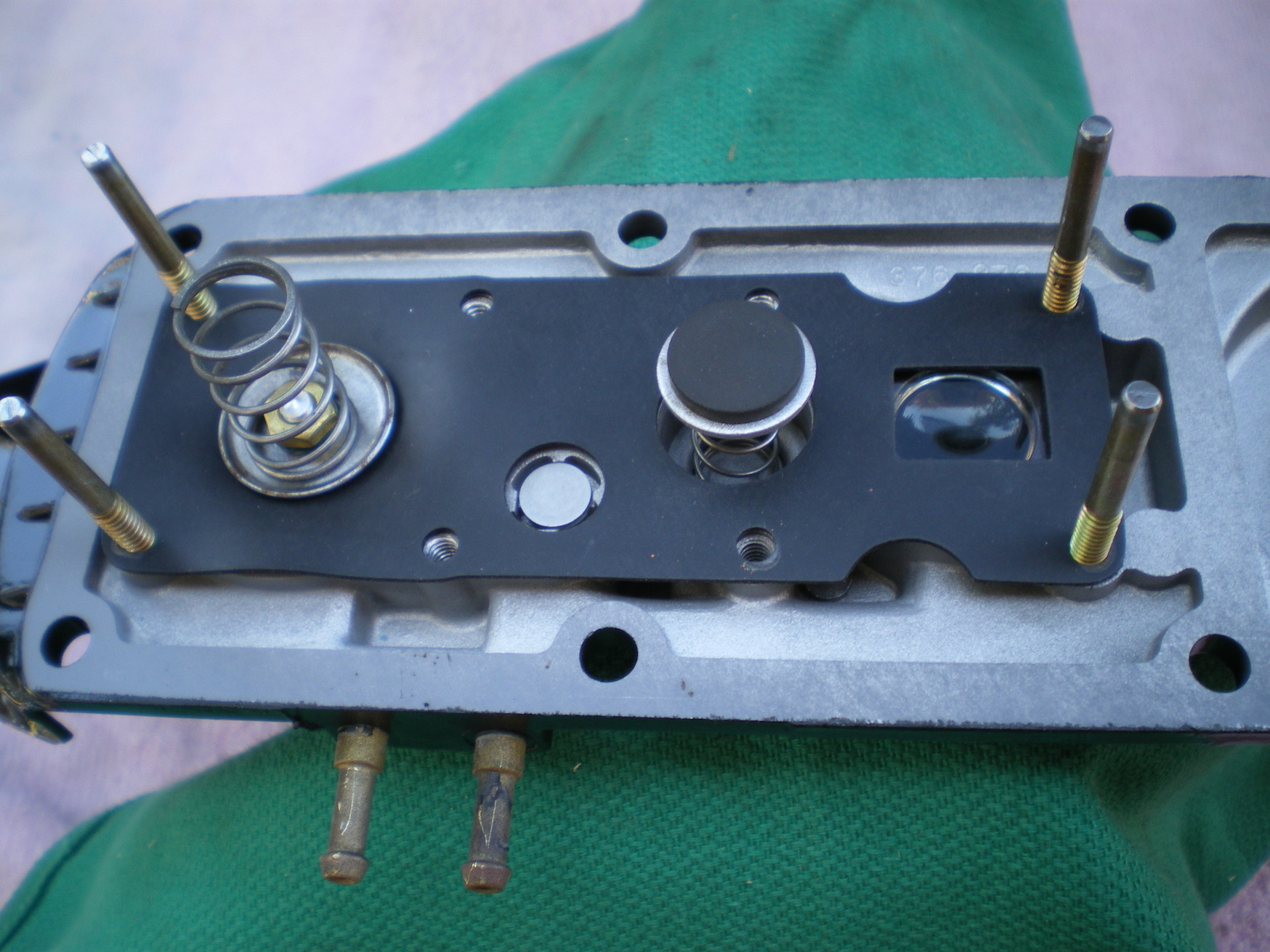

Mumbles also posted the first picture. the temporary bolts with heads cut off aid in lining things up until you get the other screws in. Works well.

October 2, 2017 at 11:22 am #65660Thanks Guys,

I did a tank on Saturday. It took about 20-30 minutes and worked great. I have always had tanks hand that worked, but was in a jam and realized that I had never done one. The bolts would make holding the diaphragm flat easier. I will try that next time. I took two motor out and ran them on Saturday afternoon with my fresh tank.Thanks again.

October 2, 2017 at 9:19 pm #65676 -

AuthorPosts

- You must be logged in to reply to this topic.