Home › Forum › Ask A Member › Ruddertwin Compression

- This topic has 7 replies, 5 voices, and was last updated 9 years ago by

slim60.

-

AuthorPosts

-

January 21, 2017 at 3:04 am #6154

My ’22 Elto Ruddertwin has 50 psi on both cylinders when I turn the flywheel by hand. Is this acceptible?

January 21, 2017 at 9:50 am #51449I know nothing about that engine but 50 seems low to for a fuel ➡ compression ➡ spark engine, and wouldn’t turning by hand crank probably give low numbers ❓

January 21, 2017 at 12:19 pm #51450I agree with zul8ter. I don’t think you can get a true value turning the flywheel by hand. Does the motor feel like it has good compression when you turn it by hand? If not, then you probably have an issue. Otherwise, I wouldn’t be too concerned. I’d be surprised if these engines ever had much compression. You could always try to fire it and see if it runs. That’s the real test.

Wayne

Upper Canada Chapteruccaomci.com

January 21, 2017 at 4:22 pm #51455Compressing ratios in the early 20’s were barely over

4to1 because the gas was so poor so 60 lbs. isn’t bad for

a motor from that time. Getting a motor to run can free

up rings that are stuck from sitting and bring the

numbers up some but your never going to get the numbers

you find in the motors from the 50’s and be on. See if

you can get your you motor running and see how it does.

Run it for a few days and see if you notice any improvement.

If you do that would indicate that the rings are freeing up.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

January 22, 2017 at 4:13 am #51487It has not run for me since there is no spark. I ordered a coil so it can be tested when the weather permits. Thanks.

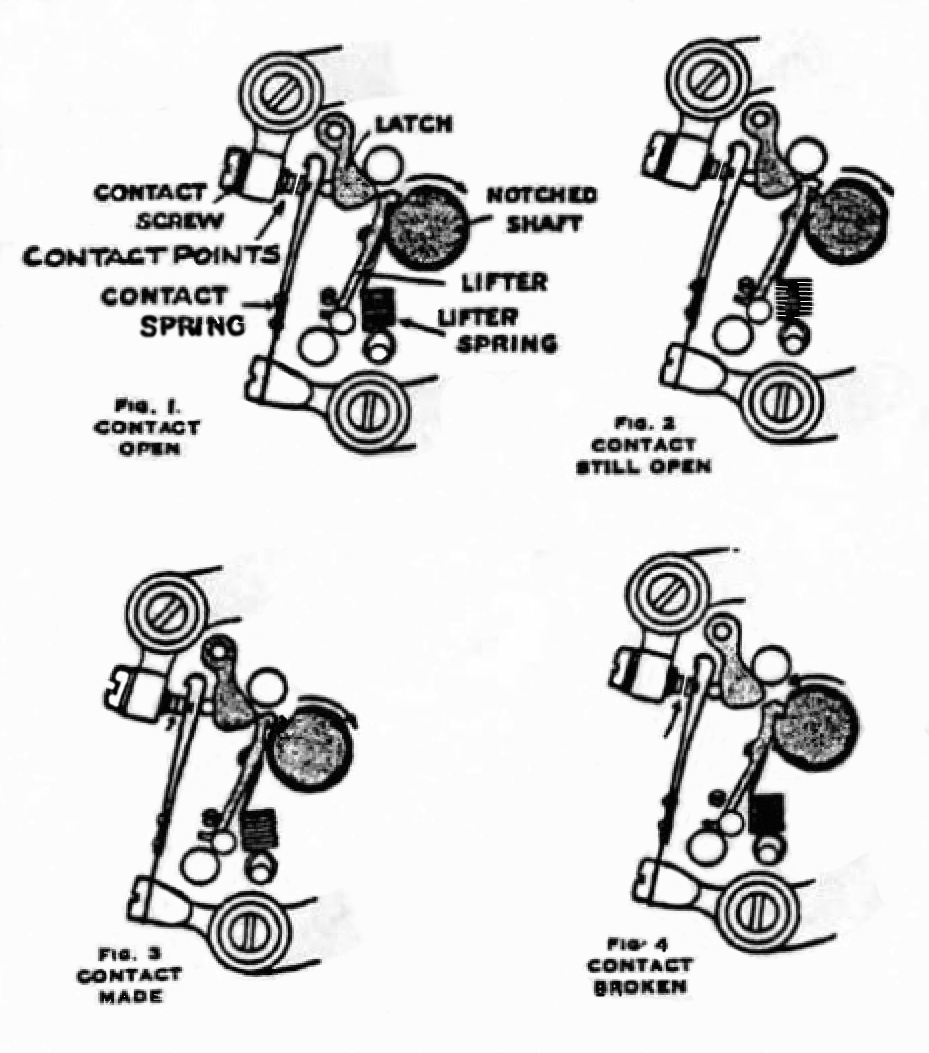

January 22, 2017 at 11:18 pm #51521The flywheel should turn freely through about 40 degrees around bottom dead center. If you flip it and it bounces back, you are OK. The Atwater Kent ignition system used is the most efficient system ever devised. There its no current draw unless the engine its running. The breaker points remain open at 0.009" until the flywheel is turned. The "dog bone" connecting rod rides on a crankshaft eccentric that rocks the notched shaft back and forth. These special breaker points latch on to the notch in the shaft and are pulled out increasing the point gap. When released the weight causes them the snap shut giving a millisecond pulse of electricity firing the spark plug. Lightfour and Zephyr coils may also be used. . . 😉

January 23, 2017 at 3:20 am #51535January 24, 2017 at 3:46 am #51601

January 23, 2017 at 3:20 am #51535January 24, 2017 at 3:46 am #51601 -

AuthorPosts

- You must be logged in to reply to this topic.