Home › Forum › Ask A Member › steering friction adjustment screw

- This topic has 20 replies, 10 voices, and was last updated 2 years, 8 months ago by

fleetwin.

-

AuthorPosts

-

April 9, 2023 at 3:53 pm #274983

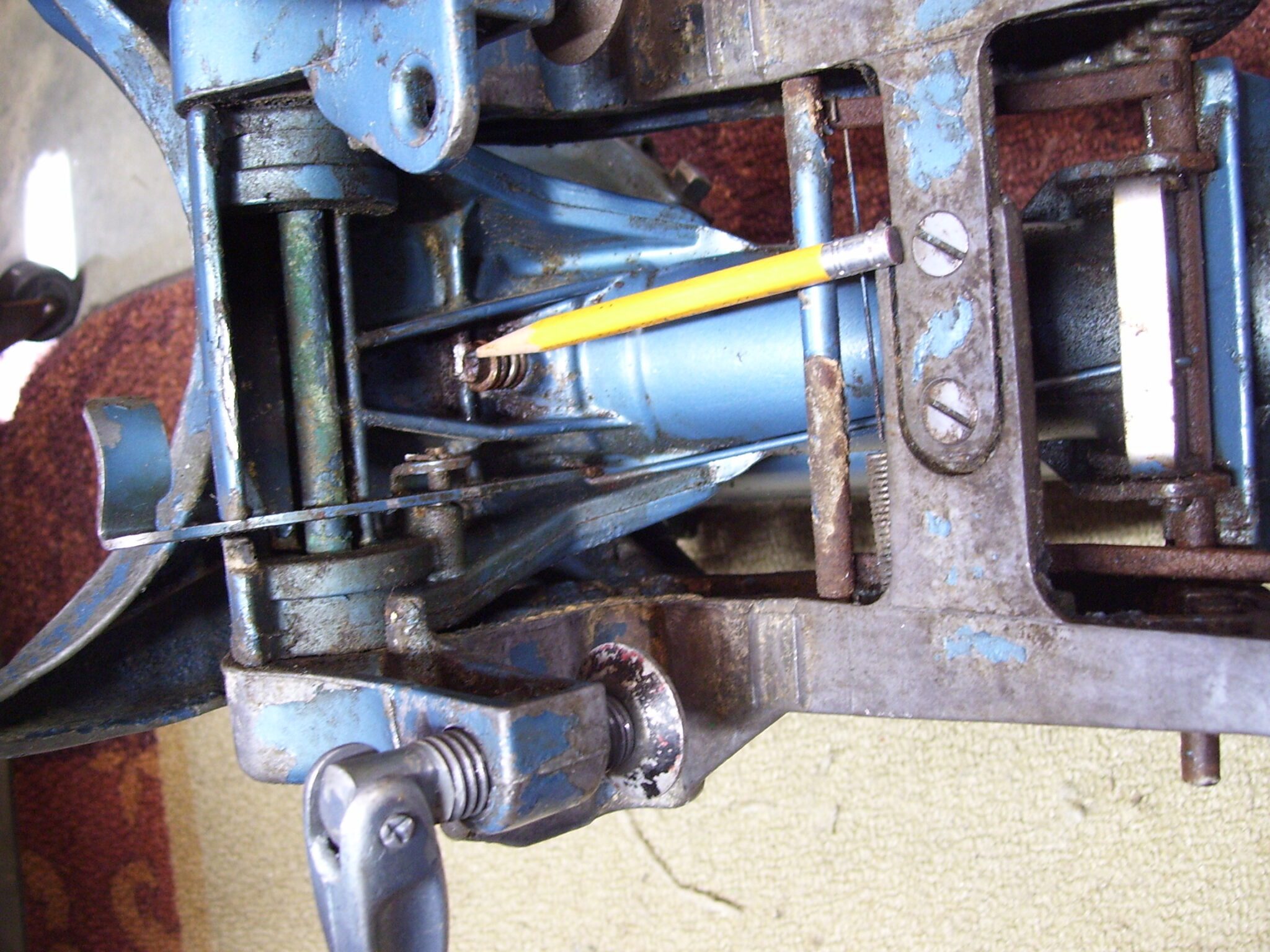

The steering friction screw on my 1956 Evinrude 15 HP is stuck. I used an impact driver and as the photo shows damaged the screw slot . I expect the screw head to break off if I continue. Then I will have to drill the screw out.

Just wondering what the drill may hit internally. Does anyone have experience with this? Any other suggestions?

Thank you.

April 9, 2023 at 4:10 pm #274985use a proper flat blade to fit the slot

try to heat up the bolt head only and then spray a release agent on the threads (wd40 etc…) try a few a few times let it soak

try to screw in the thing before screwing it out

patience brings joy…..

Joining AOMCI has priviledges 🙂

1 user thanked author for this post.

April 9, 2023 at 4:27 pm #274986Let time be your helper on this. Suggest applying some heat ( propane torch) to the aluminum boss that the screw goes into… just warm, not enough to burn the paint. Appy penetration oil ( I don’t think much of WD40 as a penetrant) , then light hammer, tap – tap on the head of the screw. Then go have beer. Come back a few hours later and repeat, and repeat … maybe until you run out of beer. Can you grab the head with vice grips? maybe a long nose pair?

Joe B

1 user thanked author for this post.

April 9, 2023 at 6:04 pm #274990will not harm paint

https://www.amazon.com/CRC-Freeze-Off-Super-Penetrant/dp/B000TFTH00?th=11 user thanked author for this post.

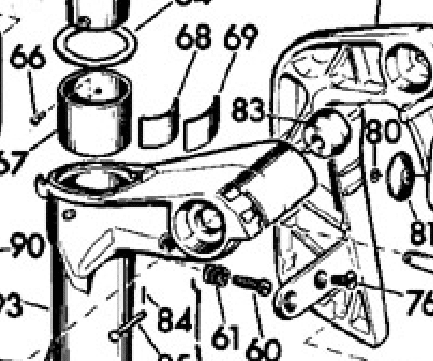

April 9, 2023 at 6:17 pm #274991The screw goes through the casting, bangs up against a brass plate #69, which squeezes a rubber spacer #68 against the liner #67. The liner is slitted which allows it to squeeze down on the pivot shaft to increase the friction.

You didn’t say, is the steering too tight or too loose? If too tight, backing off on the screw probably won’t help because the problem likely is corrosion. The cure for that is take it apart and dig the corrosion out. A common problem here in the land of salt and sea. Done lots of them.

April 9, 2023 at 6:27 pm #274994Joe B has it right – this one is a case for patience. I have had a couple of these friction adjustment screws stuck and finally got them loose with multiple applications of heat and penetrating oil. As outboardnut suggested, I have used CRC freeze-off on other stuck fasteners – in that case, I would apply heat to the boss the screw goes into then immediately apply the Freeze-off to the screw.

Best to see if you can get hold of the screw with some vise-grips and get it out rather than trying to drill it out. In the event you have to drill it out, the enclosed pic shows what’s inside the steering tube behind the screw – a metal plate and a rubber spacer sheet and a shaft liner piece (hope the pictures comes through).

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."April 9, 2023 at 6:28 pm #274996Frank,

The steering is a little tight. I could probably use it as is but looser would be easier on the cable steering. Good to know that if I have to drill the brass and rubber can be replaced if I mess up.

Thank you.

April 9, 2023 at 6:33 pm #274998Frank beat me to it!

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."April 9, 2023 at 7:32 pm #275004Bob,

Thank you for the photos.

April 9, 2023 at 9:38 pm #275006As bobw indicates, one needs to consider the relative thermal expansion rates of the two dissimilar materials here. Aluminum expands about twice as much as steel at the same temperature. Heating the aluminum and cooling the steel screw will maximize any potential gap between the two pieces allowing for the possible entry of a penetrant.

Note the words “potential” and “possible” …. a bit of old fashioned luck may come into play as well

Joe b

-

AuthorPosts

- You must be logged in to reply to this topic.