Home › Forum › Ask A Member › stripped spark plug thread

- This topic has 25 replies, 14 voices, and was last updated 8 years, 9 months ago by

rudderless.

-

AuthorPosts

-

September 3, 2015 at 9:49 pm #23130

There’s nothing wrong with using Heli Coil products for repairing damaged spark plug threads as long as you use the correct item for the application. Standard Heli Coils are nothing more than a wound piece of wire and are meant for repairing internal threads of bolt holes etc. Spark plug threads are different and require the use of a Heli Coil Spark Plug Insert to do the job right. When installed correctly, believe me, they will not come out with the plug and have much better sealing and heat transfer properties than a standard Heli Coil thread repair insert.

The Kit.

Various size inserts.

Standard thread repair inserts. See the difference?

September 4, 2015 at 1:38 am #23146

September 4, 2015 at 1:38 am #23146I 2nd that post from Mumbles, I’ve seen repair shops, and local yocals, use the standard thread repair inserts instead of the ‘save a thread’ plug hole ones (which is what I prefer). If you use the 2nd picture mumbles posted, you run into all those problems I posted about.

September 4, 2015 at 3:39 pm #23195Guys,

Thank you all for the great advice! I particularly appreciate the info on plug thread inserts and about the possibility of a plugged drain. That could save so much aggravation.

Should I remove the head to do the plug thread insert?

Thanks again.September 4, 2015 at 3:42 pm #23196I would…not worth chancing letting any of the bits of metal float around the cylinder and scratch things up to lose compression.

September 4, 2015 at 4:38 pm #23198It is very important to get the insert in square to the head face. Not all of us are machinist like Mumbles apparently is by some of the GREAT work we have seen him do. That is another good reason to take the cylinder head off. Even though the insert is a Heli-Coil product, I have always considered a Heli-Coil the second product. Just the threads which in my book are worthless even for bolt thread replacement. I have had a complete set of those (10/32 to spark plug sizes) in stainless steel for 25 yrs. I won’t use them. I only use stainless steel inserts, but they have never been Heli-Coil brand. I have always used an industrial brand because of cost and availibilty in quantities. I have seen too many problems with Heli-Coils in the way they were installed and come loose. Again just my opinion.

Dan in TN

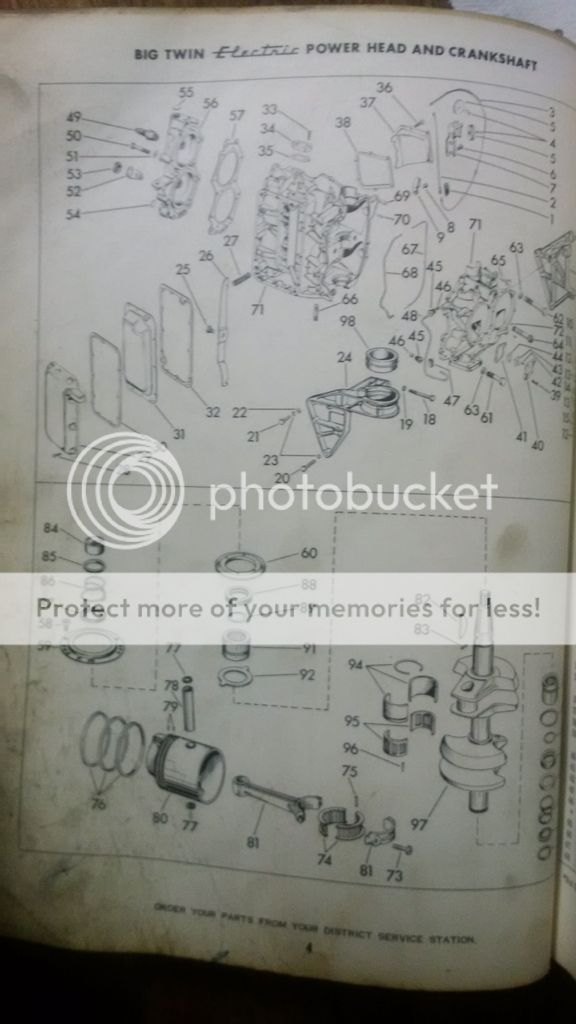

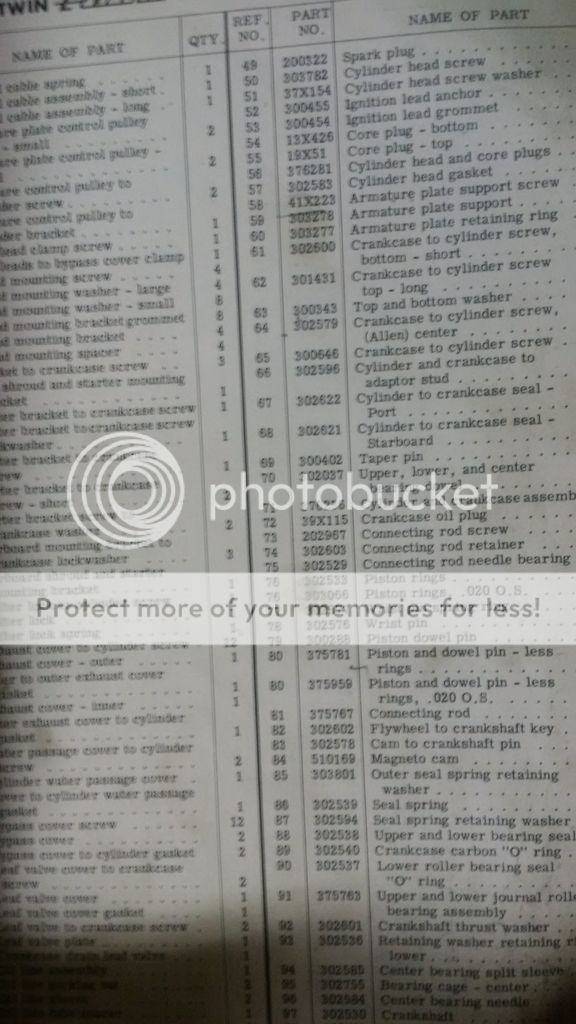

September 4, 2015 at 4:48 pm #23200Can someone post the powerhead parts breakdown for this engine so we can confirm/deny upper bearing oring usage?

September 4, 2015 at 5:55 pm #23201September 5, 2015 at 4:44 am #23259I am telling you about the first query, if you want to save money it will be better if you make it tight with the use of thread even then if your problem is not get solved you have to take new part. In relation to your second query I advice you to take the advice of professional mechanic.

September 5, 2015 at 8:08 am #23265Well, the heads for the older 25’s are getting hard to find and a bit pricey, so I would fix the one you have. I would not pull the head though, because the head gaskets are over $25 too. It’s easy enough to install the heli-coils and clean the cylinders out afterward.

You could actually clean the shavings out pretty easily. I’ve done it.April 16, 2017 at 12:01 pm #56165As it may help someone else with the same problem, I tried the Helicoil Save a Thread insert kit on my 54 Evinrude 25 HP. The head did not tap well. The tap tore the aluminum head material without cutting clean threads. The head is quite thin so the tapped thread was short. The insert just pulled out. For 1950s big twins I recommend finding another head (which I did) or maybe welding the thread area and retapping. That’s just my 2 cents. Others clearly have had better experience, but maybe not with this engine. I surely do appreciate the advice and comments above. Thank you.

-

AuthorPosts

- You must be logged in to reply to this topic.