Home › Forum › Ask A Member › TN28 Lower Unit

- This topic has 15 replies, 6 voices, and was last updated 5 years ago by

frankr.

frankr.

-

AuthorPosts

-

December 12, 2020 at 6:48 pm #225062

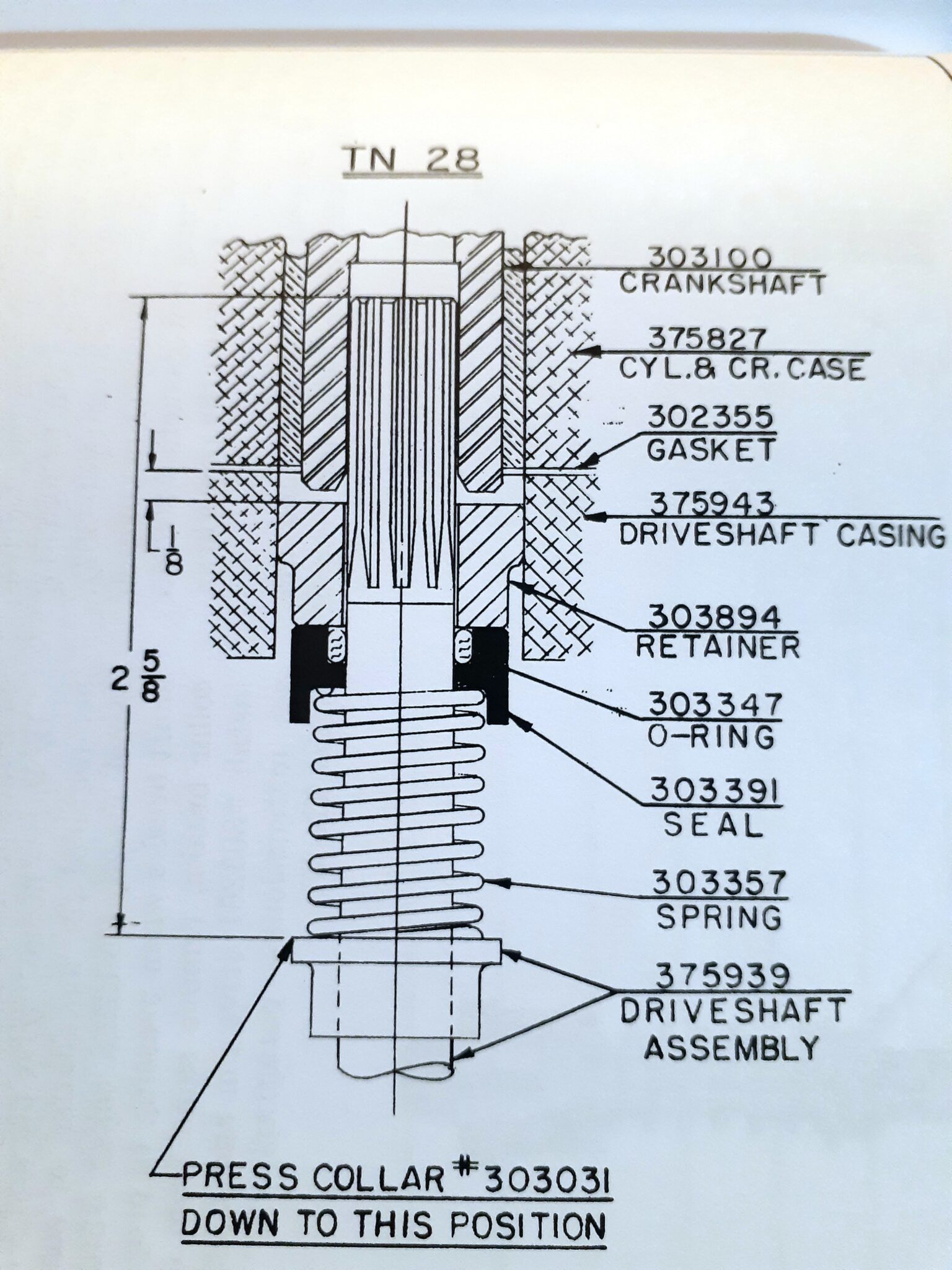

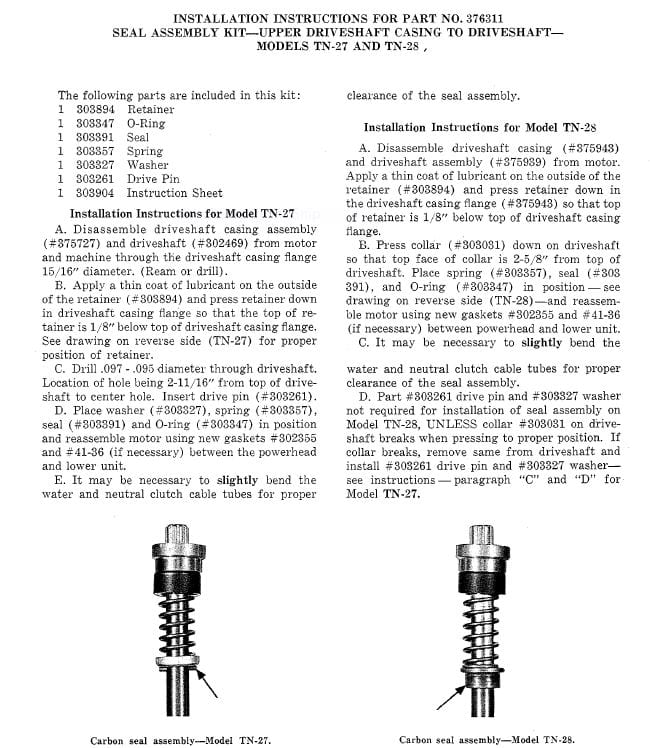

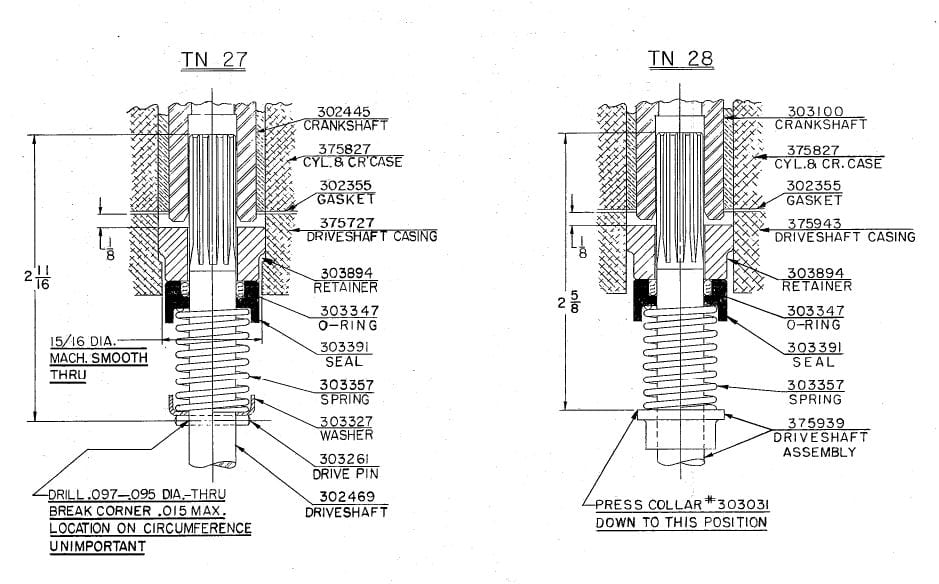

I’m new to this. Got this immaculate, original condition TN28. One owner. Has never seen water since 1953. Pulled the lower unit to change water pump impeller. That part went okay. At the top of the drive shaft, below the spline there is a press collar. A part that stayed in the housing dropped out. It is an a grommet O-ring combination. Used a flashlight to check what else was up there. Nothing. pulled the manual that I bought. It shows a spring that is nowhere to be found. I should go back and say that before this TN28 I had a junk one that I bought as a sacrifice learner. That one also lacked the spring. I am beginning to wonder if there ever was a spring. The book gives it as PN 303357. My O-ring also looks different than the 303347 that the book shows. The part is easily found on the internet.

Just very confusing to a new bee like me. I am attaching pictures. This all make me very nervous. Help is wanted and needed.-

This topic was modified 5 years ago by

Mumbles.

Mumbles.

December 12, 2020 at 10:04 pm #225085If you don’t have a spring, what was holding the carbon seal in place?

Prepare to be boarded!

December 13, 2020 at 1:32 pm #225117If you are missing the spring, any one from a later 5.5 or 6 horse thru ’79 will work. In fact, Johnson didn’t change anything and the carbon seal and O ring are the same thru ’79 to.

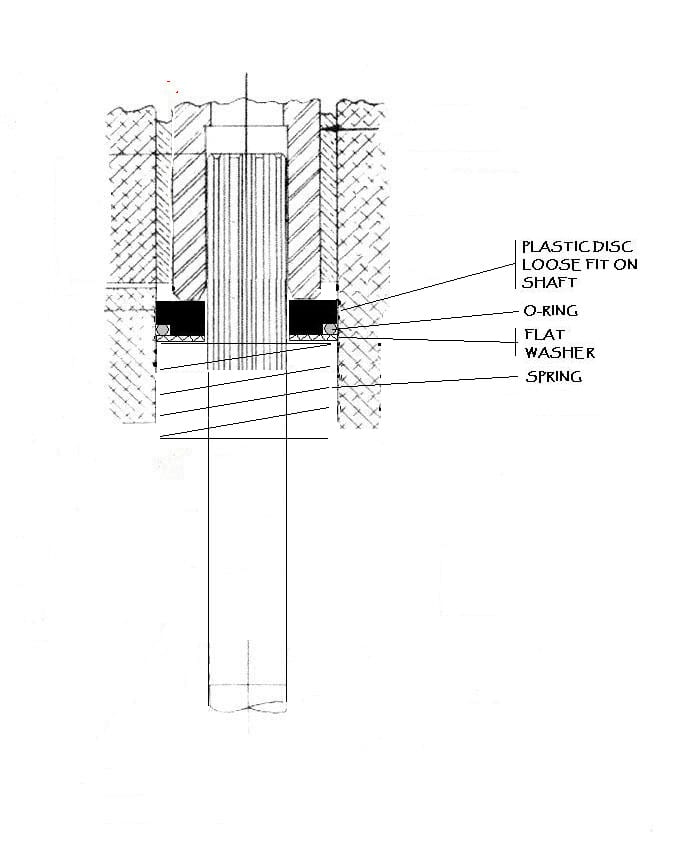

December 13, 2020 at 6:26 pm #225145December 13, 2020 at 10:59 pm #225182Buccaneer: I think that frankr has hit it. I didn’t realize that what I was looking at in the manual was a modification kit. This predates that kit. The washer and seal ride on the drive shaft collar. I’ve been told that there is no spring.

Frankr: Your diagram helps me alot. Since they fell out at different times, I did’t know which one came first. Your diagarm shows that the washer is bleow the disk and O-ring.

My new issue is that they sit so loose on the shaft that I can’t get them to align when I try to reinsert the drive shaft water pump assembly. I am beginning to worry that I have to pull the powerhead and put them in from the top. This is becoming a lot to change an impeller. Welcome to the club I guess.December 14, 2020 at 1:05 am #225189December 14, 2020 at 7:23 am #225193I’m glad you posted this. I have the same motor in about the same situation. Mine isn’t a perfect looking as yours, but not far off. It hasn’t been run since the early 60s. I think it will be my next project when I get my new shop organized in the Spring.

December 14, 2020 at 5:46 pm #225240Mumbles: Yes, that is the modification. Mine predates that modification and has what frankr sent the drawing of. I have a plan. I had the metal washer above the plastic disk and o-ring.

frankr’s diagram shows it the other way around. I’m thinking and hoping that the reason it would not go the last 1/4 of an inch is my incorrect placement of the metal washer. So, tomorrow I will flip them around and try again. I can well understand why OMC came out with the modification kit. Changing the impeller is a very common maintenance task. They likely heard a lot about this.Reivertom: Good luck with yours. They are a great motor.

Will keep everyone posted. Thanks to all.

December 14, 2020 at 8:01 pm #225248The mod kit keeps water/rust out of the crankshaft-driveshaft splines.

December 15, 2020 at 3:22 pm #225298Started over today without luck. Up against a hard place. Can align neutral clutch tube and water tube and upper driveshaft spline. Cannot get the last 1/4 inch of movement needed to close it tight. Without the washer and o-ring disk it does go all the way. So, I made an alignment tool from a wood dowel and a plastic conduit. Still won’t go. Went back to using the driveshaft as the alignment. Same results. Can’t get it closed. I will button everything back up without the washer and plastic seal o-ring.

Now I am shifting over to the practice/parts TN28 that I have. Will pull the powerhead from that and see if these seals will go in from above. You all have been very helpful. Open to any other ideas you may have. Have removed water tube and bolts and nuts from practice TN28. Now I have to persuade that powerhead to come off. I doesn’t just pull straight up as the book says it should. Will get a rubber mallet and a pry bar to “gently” persuade it. I shall endeavor to persevere.

-

This topic was modified 5 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.