Home › Forum › Ask A Member › Wear/looseness in mag plate bearing

- This topic has 13 replies, 10 voices, and was last updated 6 years, 10 months ago by

Steve D.

Steve D.

-

AuthorPosts

-

April 6, 2019 at 1:36 pm #172740

Frank, what does the ” the update kit is part #580871.” consist of? a whole new mag plate? or just the brass insert ? Is any machining work needed for truing a worn boss on the crank case?

Joe B

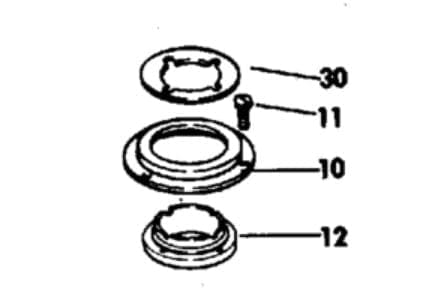

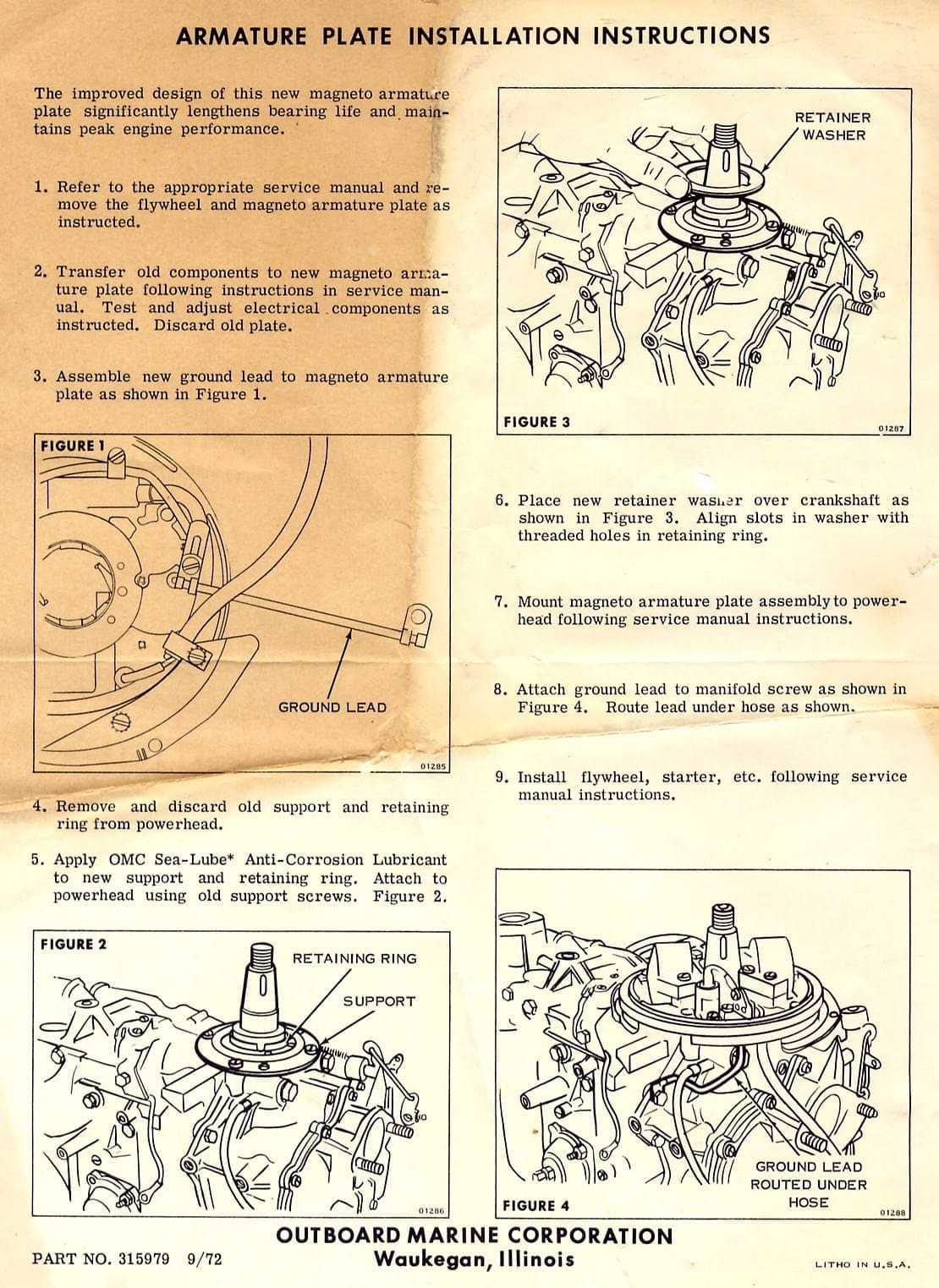

This picture is only part of the kit. The kit also includes a different mag plate. The new mag plate no longer has the brass insert that rides on the crankcase neck. Instead, the kit includes a hard-coat part #12 which takes the place of the brass insert. #12 is taller than the old brass insert, so it extends down onto unworn portion of the crankcase neck. Next goes #10 which replaces the old mounting ring. On top of that, goes #30 which is a hard-coat ring. Finally, the new mag plate. The kit also includes a ground wire, which is important because the hard-coat is non-conductive. This stuff is all shown on the 1971 40hp parts book, and some others.

I have the service bulletin, if I can find it.

No modification of the crankcase neck is necessary.

April 6, 2019 at 9:41 pm #172764Just to shed some light on the initial question of how much “slop” is there… I measured 4 mag plates and four crankcases. Now understand that these were all used parts, but none appeared to be severely worn or abused. Here are the results

Mag plate brass bushing I. D. 1.6910 , 1.6915, 1.6910, 1.6909 average 1.6911

C’ case hub 1.6870, 1.687, 1.688, 1.686 … average 1.687

So on average the clearance is 0.004″ worst case 0.0055″

I guess that in worst case the .020 point gap could be affected in the range of .015 to .025.

Joe B

-

This reply was modified 6 years, 10 months ago by

JOSEPH BRINCAT.

April 7, 2019 at 6:25 am #172781The above seems highly technical and way beyond my pay grade. I will say this, though…I once saw a 40 hp that had such bad wear that you could completely open and close the points just by moving the plate back and forth in a horizontal straight line. The thing still ran, too, barely. It shook like a paint shaker.

Long live American manufacturing!

April 7, 2019 at 7:10 am #172783 -

This reply was modified 6 years, 10 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.