Home › Forum › Ask A Member › Gasoline/Ethanol Proof Epoxy

- This topic has 8 replies, 6 voices, and was last updated 6 years, 2 months ago by

lyks2tinkr.

-

AuthorPosts

-

August 5, 2018 at 8:01 pm #10755

I just started the tear down of a 1950 Evinrude (model 4434) 7.5hp Fleetwin. A previous owner had, sometime in the distant past, attempted to repair the fuel "tank connector and filter" (p/n 276883?) with some type of epoxy. The epoxy had turned to dust – probably very early stuff. The filter assembly fell out of the tank and left a perfectly clean hole in the tank. The aluminum part of the "filter assembly" appears corroded in parts.

I have two questions: 1) does this assembly screw into the tank? The parts manual calls it a separate part number. 2) Is there, on the market, an epoxy that could be used to re-install the "connector and filter" assembly I have, back into the tank? I have some Blue Magic QuickSteel that states it can be used on fuel tank leaks. I don’t trust it on a rebuild. Is there another brand that truly will work in a submerged gasoline/ethonal environment?

I hate to go to the effort to restore an outboard only to have the fuel fitting leak. If the p/n 276883 somehow threads into the tank then I will go on the search for one and properly repair the tank. The tank is very clean and I sure hate to not put it back in use.

Thanks for the help,

DrifterAugust 5, 2018 at 8:22 pm #80689Well, rats. I just went out and looked more carefully at the tank, and it appears that the "connector and filter" is thread into an aluminum fitting that is factory (welded?) to the tank. The tank hole is clean but the corrosion on the aluminum fitting caused the fitting to fail. So, unless I can find another solution, my only option may be to epoxy the corroded fitting or aluminum weld the corroded fitting to the -very thin-aluminum tank.

Any ideas would be greatly appreciated.August 5, 2018 at 8:58 pm #80692A few years ago I showed how I repaired some Johnson and Evinrude tanks with bad threads by making an insert for them. The original threads were drilled and tapped to fit the insert which was sealed and held in with Marine Tex epoxy. The internal threads of the insert were the same size as the originals so an original fuel tap or fitting could be used.

August 6, 2018 at 2:34 pm #80715It looks like there is a "Heli Coil" (or competitor) for 1/8 or 1/4 pipe thread. Is there enough "meat" in the tank boss to use something like that?

August 6, 2018 at 2:56 pm #80716Getting back to the OP… epoxies and gasoline. In my experience, I have not found any epoxy that will hold up under continuous and long term ( days) emersion in 10 % ethanol gasoline. Now I have successfully used epoxy to repair gas tanks that see occasional use and are drained after each use, like we typically do with our old motors. Just be sure that you use real epoxy and not the polyester stuff.

Joe B

August 6, 2018 at 4:41 pm #80718Hey Joe,can you recommend a brand? I have tried Marine Tex, JB Weld, and Three Bond.

Unfortunately I experienced poor results with all three when they came in direct contact with gas.

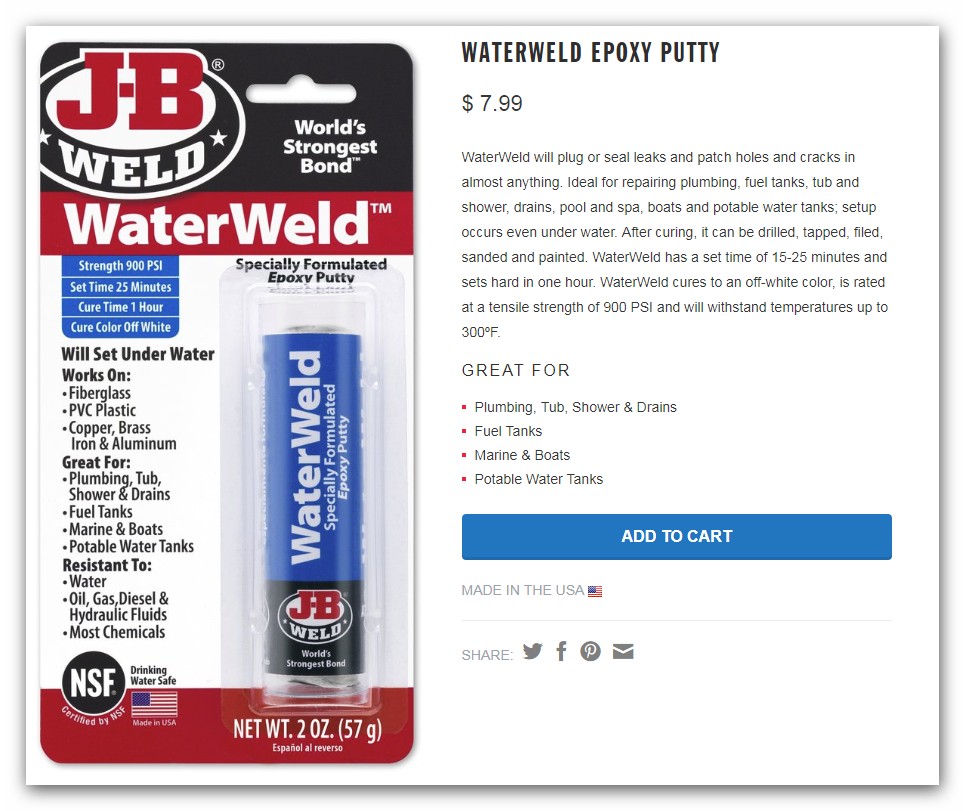

Bob DAugust 6, 2018 at 6:51 pm #80731Supposedly the JB wet weld is gas contact rated.

I just fixed a 37 Johnson 110 gas tank with it then I lined it with Damon Redkote.August 6, 2018 at 9:27 pm #80739August 6, 2018 at 9:44 pm #80740Great Bob. For extra insurance take a look at the Damon Redkote tank sealer. It’s a bit pricey per qt but you’ll get many tank linings out of it. Stays flexible. I’ve done several gas tanks and cans and have had excellent results when the instructions are followed.

-

AuthorPosts

- You must be logged in to reply to this topic.