Home › Forum › Ask A Member › 1931 Johnson OA-55 3hp.

- This topic has 22 replies, 9 voices, and was last updated 4 months, 3 weeks ago by

davidk.

davidk.

-

AuthorPosts

-

January 25, 2025 at 9:45 am #293649

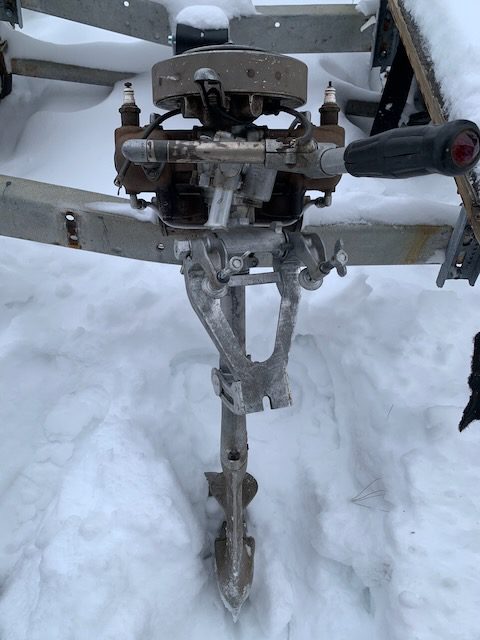

I can’t bring up your picture right now. I’m sure the issue will be resolved shortly. But looking at your thumb nail, you have the best one I have ever seen.

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

January 31, 2025 at 11:35 am #293766

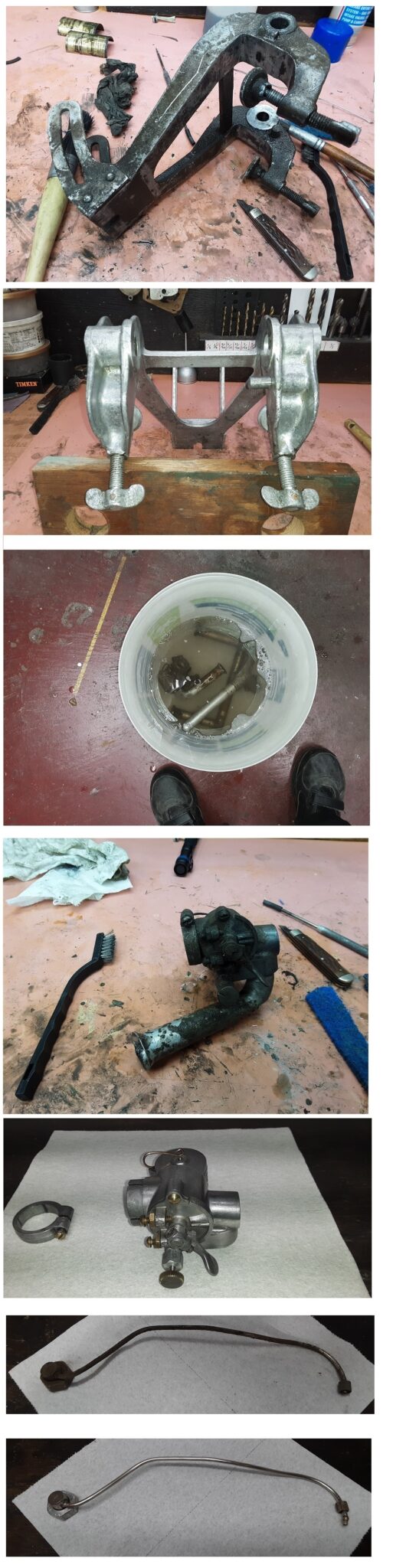

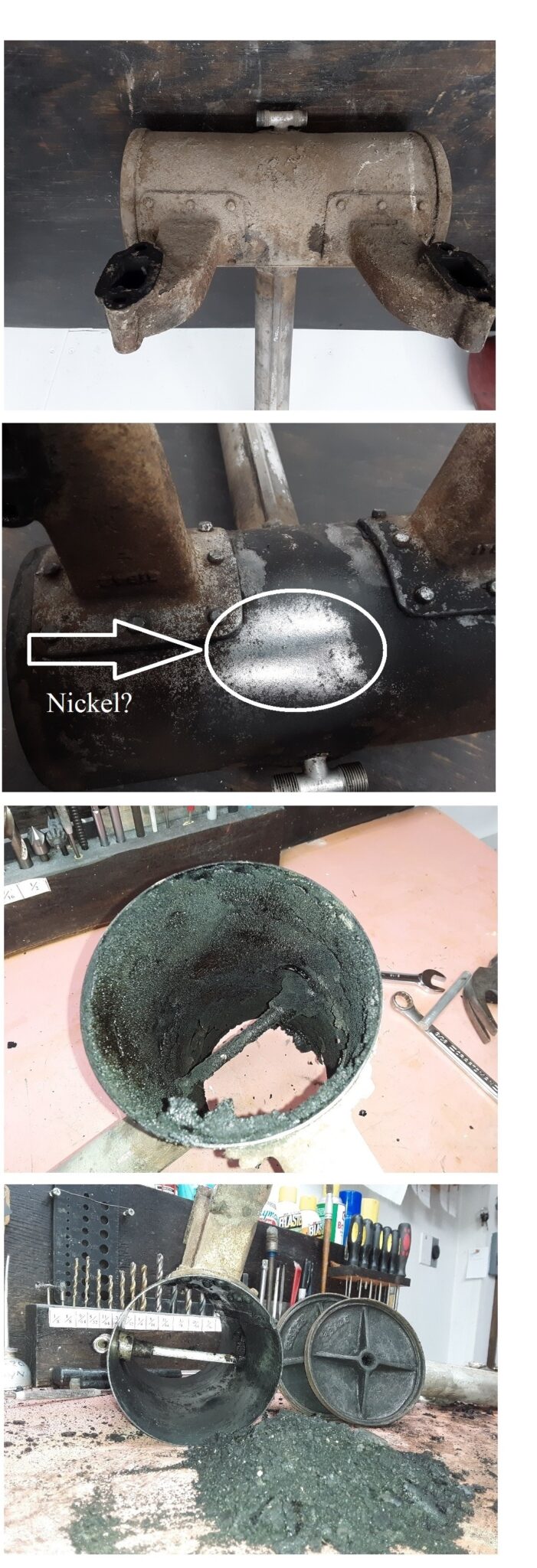

Been cleaning. The coating on this motor is really something. Where it was mixed with gear oil it came off pretty easily using some engine degreaser. The rest is mostly dirt so petroleum solvents have little effect. A water based degreaser would dissolve about half of what was on there. Removing the rest required a wire brush, steel wool, a scratch pad or any combination of the 3, and some other special tools, being careful not to damaging the part underneath. Not complaining. Its like unwrapping a gift to find what’s inside. Sometimes it makes me happy, other times, not so much. I tried soaking a few parts in a bucket of warm water. Tried biodegradable paint remover on part of the powerhead. They didn’t work any better than what I was using. Both screws were frozen on the transom clamp. One is bent. Trailer ride? Straightened it as best I could. Found some light tan paint on the gear case. Original? The fuel line still has most all of its nickel plating. Got everything stuck, freed up. Few more parts to go. This motor shows signs of significant use but its condition is not near as bad as I was thinking.

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

January 31, 2025 at 9:56 pm #293771January 31, 2025 at 10:51 pm #293773

I can see why. Yours looks a bit nicer than mine. Epically your gas tank. I have quite a bit more to do before I will know if this one will run.

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

February 5, 2025 at 10:21 am #293865

Cleaning the muffler was quite a chore. I need to get all the carbon out before I can try to remove the dents. I have read that the muffler was nickel plated. I was skeptical but it appears to be true. I saved the flywheel for last. I knew it was going to need sanding. I have quite a bit of time in both of these. The flywheel is ready for the buffer when the weather gets better.

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

February 8, 2025 at 8:43 pm #293987Tubs following the progress. It’s looking great.

What were the different grades of paper you used for sanding the flywheel? Wet or dry?

It really doesn’t even look like it needs a buffing wheel. The plugs came out amazing as well. They will look so much better than a new set of Champions.Bob D

February 8, 2025 at 11:17 pm #293988

Bob, I find the fastest way for me, to get past the pitting and staining, is to use 320 first. I have to accept that some bruises are just too deep to remove. Then 400. I find that 220 will get you into good material quicker, but the time it takes to get the 220 scratches out seems to be more work than just starting with 320. By the time I have gone around the flywheel twice I’ve usually had enough of it. I find that the 400 surface buffs up, on a buffer, fairly easily for me. I wet sand using a spray bottle rather than a bucket of water. I’ve done a few model A flywheels and the quality of the aluminum from the Lynite Company is significant better than their castings for the earlier motors.

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

February 9, 2025 at 12:08 pm #294000Tubs, wow you started out with 320 with all of the pitting.

It’s very interesting that if you use 220 you have to work on all the scratches. Never realized that.

Lesson to all, if you think you can use a courser grade to initially save time, it will come back to bite you later.

Waiting for the master class on the tank.

Thanks for documenting all of your progress so far.Bob D

February 9, 2025 at 1:52 pm #294004I found this forgotten project in the barn. “Forgotten” because I broke one of the water lines and couldn’t find a good replacement so I put it on the rack and moved on. Posting these photos to show another example. Looks to have the same paint on the lower unit, and the flywheel, that you were wondering about Tubs.

February 9, 2025 at 1:57 pm #294009 -

AuthorPosts

- You must be logged in to reply to this topic.