Home › Forum › Ask A Member › 1931 Johnson OA-55 3hp.

- This topic has 29 replies, 12 voices, and was last updated 1 month, 3 weeks ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

February 9, 2025 at 2:00 pm #294014February 9, 2025 at 8:35 pm #294020

Thanks for the pictures David. I cleaned most of it off of my gear case except for under the cave plate. Save it there for a color match if I or someone in the future should want to go that way. I’m feeling better about my gas tank after seeing yours. If you would like to get that motor back on track here is someone who sells that aluminum tubing by the foot. You’ll have to use brass compression sleeves though.

https://www.ebay.com/itm/174359334934

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

February 9, 2025 at 10:38 pm #294027Thanks for the link on that tubing, Tubs. I’ll check it out.

December 12, 2025 at 11:02 am #302276Here is our OA55. It is a New England motor but now resides in Tampa Florida with the rest of our permanent collection. Sincerely, Matt Penn

December 13, 2025 at 12:14 pm #302298

Ran my OA-55 last summer. Working on a You Tube video. It will have some of what was posted here. The link is to what will be the ending of that video. This is a new camera. I dropped my other one and chipped the lens. They come with a waterproof case so I kept this camera in it to protect it. Well that seems to muffle the sound some. That and the times I have the tiller resting on my camera mount distorts the audio. Later on in the summer I started getting some pre-ignition in the starboard cylinder when starting and trying to run slow. I’ll post some pictures of what I found when I get a chance.

Video link https://youtu.be/-V-pMaYLdTk

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

December 13, 2025 at 5:47 pm #302309Guess I might as show my OA-55 test run from a few seasons ago.

Prepare to be boarded!

December 16, 2025 at 9:02 am #302340For some of the dents, you might be able to get a suction cup with a slide hammer to work. If there is a good reason not to use this method in general, let me know.

- Max

December 20, 2025 at 3:37 am #302456Certainly an interesting little motor Tubs.

Keep us posted with progress. I’m sure you will make a great job of it!

I have seen the use of a ball bearing in restoring the damaged pipe work on a trumpet, so I’m sure you will make a great job of the horn with that method.

Monte NZ

December 21, 2025 at 10:40 pm #302520

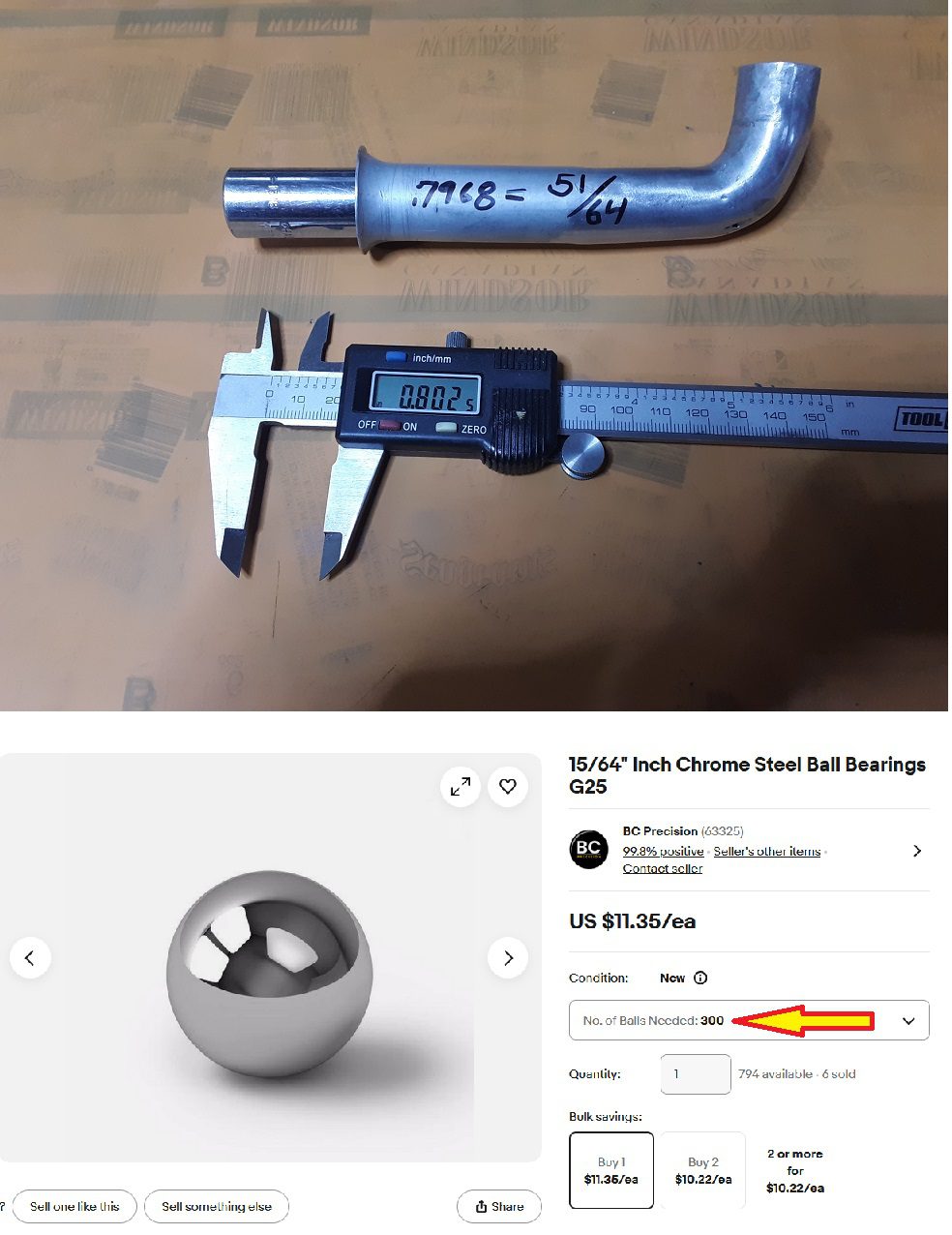

In my attempts to try using a ball bearing the straighten these air horns, I have discovered a major problem. This socket is exactly the right size to remove dents from the straight part of the air horn. It just fits. Its outside dia. is about 0.800. The nearest fraction would be 51/64th. (0.796). A bearing that size would probably straighten the bend in the air horn. I would also need a couple smaller bearings to work up to the 51/64th bearing. The problem is finding a 51/64th (0.796 or 20.23mm) ball bearing. I have spent some time looking. I thought I had found one but my head flipped the 15 around to 51 and it was awhile before I realized it wasn’t what I thought it was. Don’t know what I would have done with 300 of them.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

December 22, 2025 at 8:33 am #302524With all those “steelies”, you could go to the local grade school

and clean house at recess playing marbles!If one had a tubing bender, it might be easier to make new

air horns than trying to straighten the old ones.

Most are really in bad shape.Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.