Home › Forum › Ask A Member › 1932 Johnson K-50 8 hp questions

- This topic has 20 replies, 8 voices, and was last updated 6 years ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

April 18, 2018 at 11:00 pm #9683

I started on the subject motor today. It seems pretty sound.

It’s missing the cover for the carb float chamber (I can probably

make something to work on the lathe), the float needle is broken

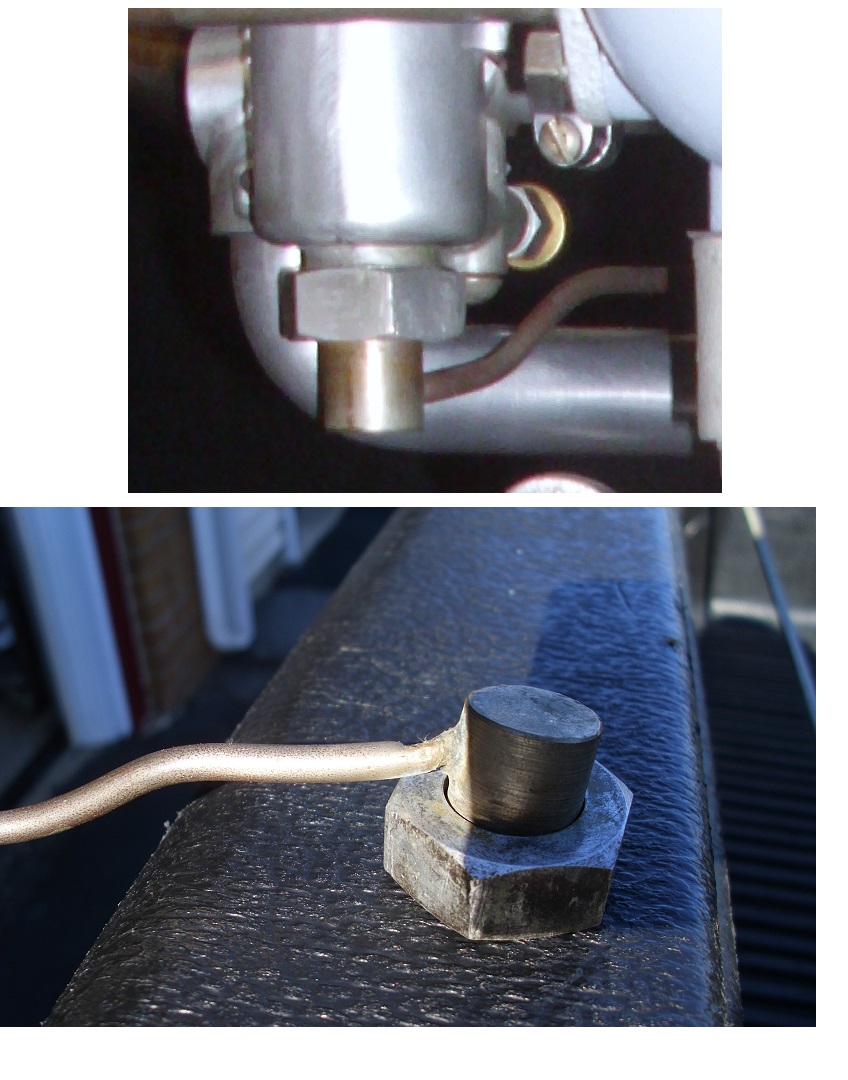

in half, and one gas tank mount ear is broke off the tank.Anyone have photos of this carb I can compare?

I’m wondering if the 90 deg. fitting below the needle seat

and the seat itself, is correct. It really doesn’t look like

the needle would seat at all.When I took the magneto off I noticed it had conventional style

condensers installed, but the old original rectanglar condensers

are still mounted and wired up as well.

I tested for spark before I tore it apart, and there was none,

but the points look pretty crusty.

Would it spark at all with the condensers "doubled up" ?

Thanks!Prepare to be boarded!

April 19, 2018 at 3:46 am #74302Not sure about the carb but with the caps hooked up in parallel, the uF rating would be the total of the two. For example, if you wire two 0.10 caps in parallel, it would be equivalent to a single 0.20 cap in the system. If one of the original caps is shorted internally, the second one would just be going along for a ride wired in like that. Even if they were both good and within limits, the points would suffer from arcing or pitting.

April 19, 2018 at 11:11 am #74309The needle seat is above the level of that fitting. In the picture it looks like you’re attempting (or somebody else was) to use the cobbled up compression nut (if that’s what it is) as the needle seat, and that ain’t gonna work.

If the needle doesn’t go through that nut, take it off and put the needle where it should be. There’s a threaded collar on the base of the float bowl, the needle has to be above the level of those threads. If you try to use that improper nut as the seat area, I doubt the needle would be long enough to go all the way through the centre of the float.

The elbow parts might work, but no, they are not correct. Proper fuel pipe is similar to what you see on all of the antique Johnson motors, i.e. they have a fuel pipe soldered to a nickel-plated brass ferrule that is captured by an aluminum nut that threads onto the base of the fuel bowl where those male threads are.

It also looks like there’s a small barrel thing fastened onto the throttle lever, probably somebody trying to use remote throttle control on it.

Hope this helps.

Best,

PM T2April 19, 2018 at 11:49 am #74310The fuel inlet has been modified, it should look the same as your later K motors Buc, and your A. A big hex nut with the fuel line soldered on. I’ll take some pics of mine when I get in my shop, got to do jury duty today. No time. Lol

April 19, 2018 at 12:28 pm #74311Thanks for the lesson in electronics. Good to know the caps

will work in parallel if needed. Not sure how I’ll wire up new caps

when the time comes. Last time on another old Johnson I

put an axial cap in the same place as the original retangular

condenser was mounted, but I had to solder on a wire to

one lead to make it long enough to hook up to the points

terminal. Then made up a couple of tin covers to hide them.

It all seemed a little "Mickey Mouse", but it worked.quote Mumbles:Not sure about the carb but with the caps hooked up in parallel, the uF rating would be the total of the two. For example, if you wire two 0.10 caps in parallel, it would be equivalent to a single 0.20 cap in the system. If one of the original caps is shorted internally, the second one would just be going along for a ride wired in like that. Even if they were both good and within limits, the points would suffer from arcing or pitting.Prepare to be boarded!

April 19, 2018 at 12:35 pm #74312The carb was as purchased by me, and appears to have been "cobbled up"

many moons ago. So far I’m not able to get the fitting (that the needle was in)

removed, as the round brass plug affair in the inside of the carb bowl turns,

with no way to hold it.My Condolences on Jury Duty Squire……. that’s my worst nightmare,

that I’ll get "called to duty" during Tomahawk. If so, the guy may be hung, lol.quote PM T2:The needle seat is above the level of that fitting. In the picture it looks like you’re attempting (or somebody else was) to use the cobbled up compression nut (if that’s what it is) as the needle seat, and that ain’t gonna work.If the needle doesn’t go through that nut, take it off and put the needle where it should be. There’s a threaded collar on the base of the float bowl, the needle has to be above the level of those threads. If you try to use that improper nut as the seat area, I doubt the needle would be long enough to go all the way through the centre of the float.

The elbow parts might work, but no, they are not correct. Proper fuel pipe is similar to what you see on all of the antique Johnson motors, i.e. they have a fuel pipe soldered to a nickel-plated brass ferrule that is captured by an aluminum nut that threads onto the base of the fuel bowl where those male threads are.

It also looks like there’s a small barrel thing fastened onto the throttle lever, probably somebody trying to use remote throttle control on it.

Hope this helps.

Best,

PM T2Prepare to be boarded!

April 19, 2018 at 2:39 pm #74322April 19, 2018 at 4:25 pm #74330Tubs, Whoever re-engineered the fuel line fitting on the

carb did a good job. It was soldered on "factory looking."

Unfortunately, I’m guessing the guy forgot to insert the

float needle before soldering on the new fitting.

Sounds like something I would do! 😮

Little propane bottle torch wouldn’t do anything, so

I had to get the big guns out. Luckily, the needle

seat is down in the hole away, and didn’t seem affected.

I took a fuel line off a 1940 Johnson, and it screws

onto the K-50 carb body okay, even though the threads

aren’t great. Carb is soaking in cleaner. Not sure what

I’m going to do about the broken needle brass needle yet.

It appears that an attempt was made once to solder it together.

Thanks for the photos!Prepare to be boarded!

April 19, 2018 at 9:50 pm #74346Spent some time on the carb today. I think all will be well.

Got the carb and needle seat cleaned up, the broken needle

brazed back together, new cork float made, and whittled

out a new float cover. Have to get some super glue to

seal the float tomorrow.Prepare to be boarded!

April 20, 2018 at 1:00 pm #74368Wow that’s pretty cool. Excellent work.

Joe

-

AuthorPosts

- You must be logged in to reply to this topic.