Home › Forum › Ask A Member › 1954 johnson 5.5hp seahorse

- This topic has 12 replies, 7 voices, and was last updated 4 years, 1 month ago by

Steve Fink.

-

AuthorPosts

-

June 9, 2021 at 7:33 pm #239831

Last fall, I bought this old outboard 1954 johnson 5.5hp outboard that is in incredibly good shape because it had been sitting in a cabin basement for at least 20-40 years. I have replaced the points, condensors, gas lines, spark plugs, rebuilt carb, soaked all the parts including fuel filter, recoil, oil, etc. I have gotten it to turn over, but it quits after 3-5 seconds. I get plenty of spark, it seems to be a fuel issue. I don’t smell any gas on plugs. Also, what setting should the high and low speed needles be set at while trying to start? I followed the instructions in the original owner manual on line as far as reinstalling the high/low needles. The only thing that I didn’t change in the carb was the float. The new one that came with the kit broke when I was putting it in, so I put the cork one back in. I bought the mile master gas tank and rebuilt that too, so it has good pressure. I have had a lot of fun working on this and learning quite a bit. Looking forward to getting it out on our Minnesota lakes this summer. Any ideas/suggestions ?

Thanks, Steve F

-

This topic was modified 4 years, 1 month ago by

Steve Fink.

June 9, 2021 at 8:51 pm #239853Assuming your compression is up to snuff, I’d start with the fuel system again.

Are you sure you’re able to pump the carb full of gas with the tank primer?

If the bowl is full of gas it should run longer than a few seconds if the

rest of the carb is okay.Prepare to be boarded!

1 user thanked author for this post.

June 10, 2021 at 7:43 am #239877How do the coils look? All 1954 Johnsons have bad coils unless they have already been replaced.

June 10, 2021 at 7:48 am #239879Thanks for the response ! The glass bowl is full. I can go back into carb with a new float.

June 10, 2021 at 7:50 am #239880Sorry about that, I did replace the coils but I see that I didn’t mention it originally

June 10, 2021 at 11:09 am #239884It seems like it’s not getting enough fuel. Are you leaving the choke partially on after it starts? Initial settings on the mixture needles are 1 1/4 turn out on the slow speed needle and about 1/3 turn out on the high speed needle after being gently seated. Opening both of them a bit more to richen the mixture won’t hurt anything as you’ll be adjusting them as soon as the motor starts. It’s all explained in the owners manual I’ve attached.

If the tank is nearly empty, it might require additional pumping on the tank button until enough pressure is built up in it to supply fuel to the carb. Not so much with a full tank.

June 10, 2021 at 6:43 pm #239929Mumbles, You nailed it ! The gas tank only was a 1/4 full. I pumped it up more than before and it started up and it ran until I shut it off. NOW, you are one for one, while it was running, quite a bit of gas was coming out of the top of the priming tower on the the mile master gas tank. I had rebuilt the tank with a complete gasket kit because the old one was shot. Don’t know if I missed something, but I’m so close now to getting this beautiful old motor on the water for the first time in probably 40 years. Any advice ?

Thanks again, Steve

June 10, 2021 at 10:51 pm #239949Glad you got the fuel supply problem figured out so I’ll try for two out of two!

Fuel coming out from around the tanks button could be caused by two things. Since fuel is only on the bottom side of the diaphragm, it’s either got a hole in it or it is leaking around the threads on the shaft. Since the diaphragm is new, the shaft is probably leaking. A bit of fuel proof sealer should be used on the threads and a small amount on the support washers which are on each side of the diaphragm to prevent any leaks. I have put them together without sealer and they’ve worked fine but that’s probably due more to luck than anything else.

-

This reply was modified 4 years, 1 month ago by

Mumbles.

Mumbles.

-

This reply was modified 4 years, 1 month ago by

Mumbles.

Mumbles.

1 user thanked author for this post.

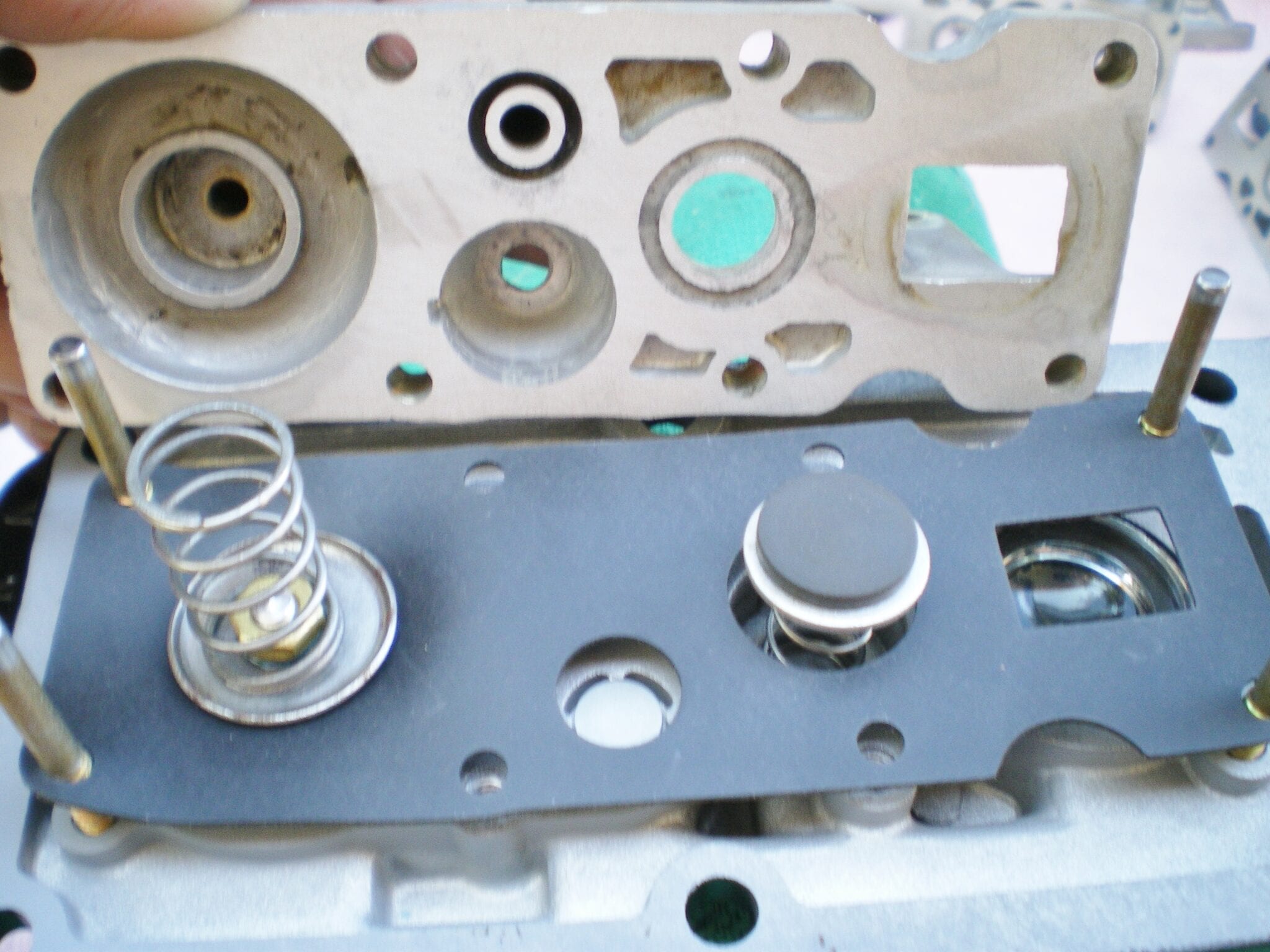

June 11, 2021 at 11:07 am #239978Steve when you get into that tank. Be sure to check the check valve in the pickup. It is on the end of the tube where the fuel screen is. You should hear it moving if you shake it. Give the pickup tube a blast of compressed air from your compressor. Air should go only one way, UP. This check needs to work to maintain pumping after motor starts. Once you get it loose it should work fine. Gunk from the bottom of the tank causes problems on gas tanks that set for a long time. Hope this helps!

dale

June 11, 2021 at 11:35 am #239982 -

This topic was modified 4 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.