Home › Forum › Ask A Member › 1956 Evinrude Big Twin #25022 water pump

- This topic has 30 replies, 8 voices, and was last updated 5 years, 5 months ago by

Bob Wight.

Bob Wight.

-

AuthorPosts

-

January 5, 2020 at 6:10 pm #191078

Disappeared post

Dare I try again? January 5, 2020 at 6:14 pm #191079

January 5, 2020 at 6:14 pm #191079

Be sure the four holes in the water by-pass cover are towards the front. January 5, 2020 at 6:48 pm #191082

January 5, 2020 at 6:48 pm #191082Thanks for all the input.

All the holes are clear. I tend to be a better parts cleaner than anything else.

Some motors call for a gasket below wear plate. Some not. We have not been installing one on this motor, but that must be the issue.

Thanks again.

And Frankr , if you’re still in FL, will you be going to the Lake Hamilton swap meet?

Hope to be able to meet you in person if so.

That actually applies to any of the guys in FL who have been helping me out so much!

GeerActually, I do plan to go to Lake Hamilton–I hope I’m able. I’m fighting a health problem. If I do go, I’m bringing my 1918 Evinrude RBM, with hopes of finding a home for it. I started restoration on it several years ago and have lost interest. My loss will be someone’s gain.

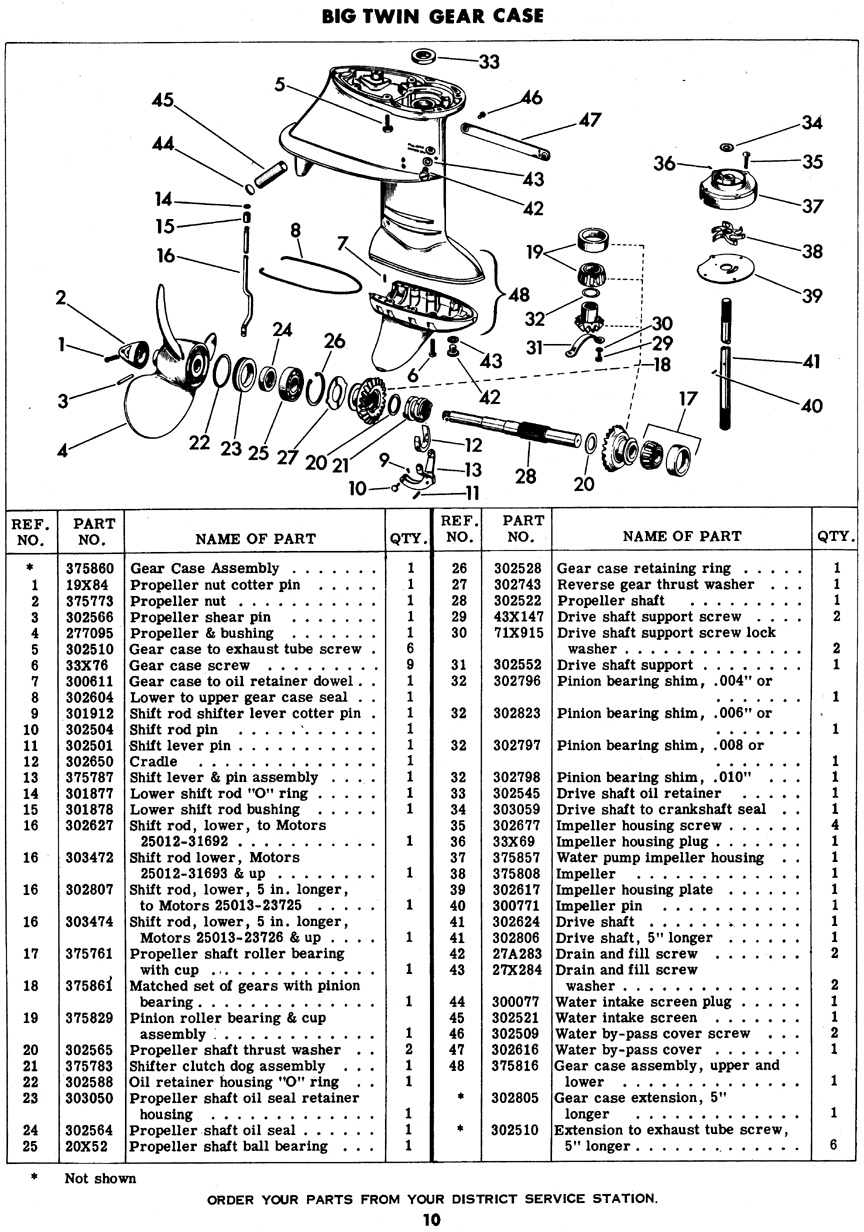

January 5, 2020 at 9:06 pm #191084I gotta get my two cents in on this tread. Forgive me if I am outta line! You are working on a 1955 big twin correct? The parts page that Gary posted is different than the picture that Frank posted concerning the bleed hole. I have a ’51 and a ’53 big twins and the water that comes to the impeller gets sent to the power head through copper line in the back of the exhaust housing. I have not worked on the newer models. The copper line is not hooked to the impeller housing on my motors. There is a grommet that is probably whopped out in the back of the exhaust housing. The copper tube just hangs in the water passage. High pressure would make the water move to the power head but low pressure might not.

dale

January 5, 2020 at 9:08 pm #191085Ha! After I read the above advice from Garry I happened to look over at my beloved 12 horse Sea King (which has a place in the house!) and lo! The water by-pass cover is backwards!

However, it is on correctly on the big twin.

Anyway, we have not been using sealer between housing and plate. After checking for cracks we’ll apply some when putting it back together, again.

I’ll keep y’all posted on this ongoing mystery.

GJMGP

January 5, 2020 at 9:36 pm #191091Labrador-guy, your post appeared as I was hitting submit. I noticed the differences in the photos and diagrams as well. We are actually working on a 1956 big twin, #25022, so it does have a different configuration. I’ve been taking from the posts what I can use, like water by-pass cover on correctly, and looking for cracks. These issues would be universal regardless of specific year or pump style. As another example, our pump housing does not have the hole in the outlet or discharge part of the housing. There is a small hole that permits water to fill the top outside of the housing though, just in a different place. At this point all suggestions are greatly appreciated. Specially ones that come with pictures!

I’ve also been working on a 1953/54 big twin. It has the water pump configuration like the above diagram (is it hard to disconnect the shift rod or what?!!!).

Anyway we’ll make it work and if we discover how or what we did to make it work I’ll be sure to let y’all know.

And I’ll keep my eye out for that old RBM.

Thanks again!

GJMGP

January 5, 2020 at 10:19 pm #191094G,

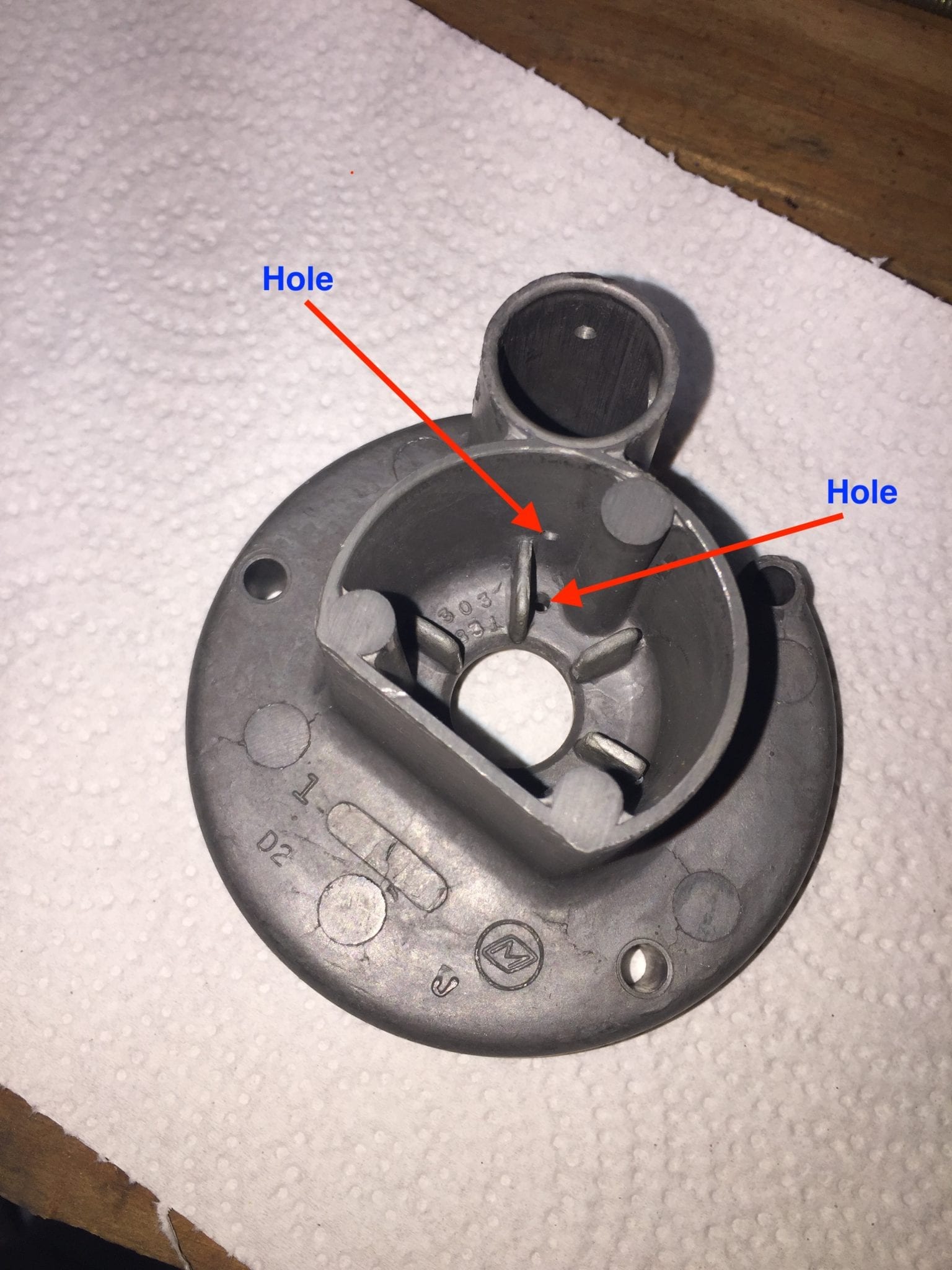

Here’s the impeller housing from my ’56 Johnson RD-18, part #303831, showing the hole locations. I assume your 56 Evinrude would use the same housing. Do you have something different?Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."January 5, 2020 at 10:20 pm #191097Here is a picture for you. Something to look for if your motor is like this one. That shifter connector is a bugger for sure! At the top of the picture you will see the up copper tube. About two inches up there is a rubber grommet. I am betting if yours is like this one the tube will be too loose to make a seal causing the water to dump into the exhaust at low RPM.

dale

January 6, 2020 at 10:26 am #191116Geer, the pump housing on your 1956 should look like the excellent picture posted by bobw. It clearly shows the angled hole that fills the well. The other hole in the bottom of the well is a drain hole for when you shut it off. The picture posted by labrador-guy is for motors pre-1955, and totally non-compatible with 1955-up. Yes, the picture I posted earlier is for smaller motors because that is what I had on file. But the way it works is the same. Hope this clears it up.

February 7, 2020 at 10:59 pm #194253Okay!

Lots of input and suggestions. All valid. Rereading the above posts I realized just how much I’ve learned! Pretty freaking cool. Ol’ Hank too. I suspect he can take off, fix, and replace that gear case and water pump with loud music playing, cars beeping, and pretty, scantily clad women dancing around him.

So, after all the trial and error, a nos wear plate was bought (suggestion of a Mr. Steve Woods) and compared to the old. The old was cupped slightly. New plate was installed and lo! She pumps! Tested on the boat and in a lake!

All is well.

Lesson learned, check the flatness (better word, what word would a machinist use, hmmmm) of the wear plate! Also, clean the diaganol hole in pump housing, which I learned was there and why(!).

Thanks again to all.

GeerJMGP

-

AuthorPosts

- You must be logged in to reply to this topic.