Home › Forum › Ask A Member › 1956 Evinrude Fleetwin 7.5hp Crank Play

- This topic has 12 replies, 6 voices, and was last updated 3 years, 6 months ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

November 11, 2020 at 9:08 pm #220647

I have a 1956 Evinrude Fleetwin 7.5hp that I just bought with intentions to get it running. As I was pulling it apart to do normal ignition and carb maintenance I notices there is some play in the fly wheel. I put an indicator on it and got the following results:

Radial direction ~0.0045″

Axial direction ~0.0055″I can get the crank shaft to lightly clunk when a push back and forth on the flywheel. Is this a problem? I am not to familiar with these plain bearing motors.

It seems kind of strange as this motor still has the original coils in it (which are heavily cracked) making me think it has not be used in a long time. Another interesting discovery is the cylinders have very good hone marks in them. I measured the bores at 2.125″ which I think is oversized? Can anyone confirm? Compression was 75PSI top and bottom.

Just want to make sure I have a good motor before I put any work and money into it. Any thoughts on how I should proceed?

November 11, 2020 at 11:00 pm #220649Can’t speak to the play in the crankshaft but the cylinder bore at 2.125″ is original spec, i.e. not oversize bores.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."November 12, 2020 at 7:50 am #220655First, I must say you are the first I’ve ever heard of that actually put an indicator on it and measured it. Most of us just use the wiggle-and-feel method. Anyhoo, I looked up and the radial play spec is 0.0035″ max, 0.0025 min.. So you are 0.001″ over max. Certainly not enough to worry about, in my opinion. They don’t give an axial spec, so I guess they don’t worry about that either.

November 12, 2020 at 7:53 am #2206561954 Evinrude 7.5hp shows factory bore size as 2 1/8 = 2.125 inches. Sorry away from the lap top and didn’t have the Johnson manual on my iPad.

Oh, 75 psi is good.

Definitely 16:1 fuel to oil ratio

-

This reply was modified 3 years, 7 months ago by

cajuncook1.

-

This reply was modified 3 years, 7 months ago by

cajuncook1.

November 12, 2020 at 7:11 pm #220704Thanks for the feedback everyone! I’ll go ahead with trying to get this one running. My items on the list are:

#1. Carb cleaning / rebuild

#2. Full ignition rebuild – points, coil, condenser and set the timing. <– I got the timing tool and coil ring from Richard. Thanks!

#3. Water pump impeller

#4. Pull the exhaust plate and check for blockages and pin holes in the plate.

#5. New head gasket & clean out water jackets.

#6. Pressure test the lower unitIs there anything else I should look at while I’m in the motor? Any issues these motors are famous for?

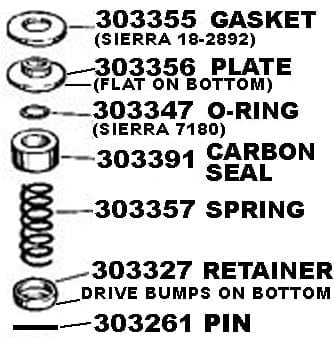

November 12, 2020 at 8:51 pm #220707My pet peeve are the guys that do a water pump job and totally ignore the carbon seal at the top of the drive shaft. If it is not in good condition, water can enter the crankcase and over a period of time cause wear and damage to the bearings. Then it tosses a rod through the case and somebody blames it on the oil. At the very least, always replace the 303355 gasket and 303347 o -ring.

Also,, it seems like broken shock absorbers in the lower unit seem to be showing up all over the place. My personal theory is that the heavy spring inside is breaking due to metal fatigue after being under stress for some 60 years.

November 12, 2020 at 9:00 pm #220711***I guess while I was making my long winded post, Frank beat me to the punch..lol Frank is spot on with his advice. It is he that drill that information that I am passing on into my head!!! Thanks Frank for passing on your knowledge, experience and wisdom!!

To change the water pump you will have to lower and remove the gear case. To do that you will have to remove the power head. With the power head off you will be able to disconnect the shift rod. While you are there it is highly advisable to change the lower crankshaft seal and o-ring. The lower crankshaft seal helps prevent water intrusion into the power head.

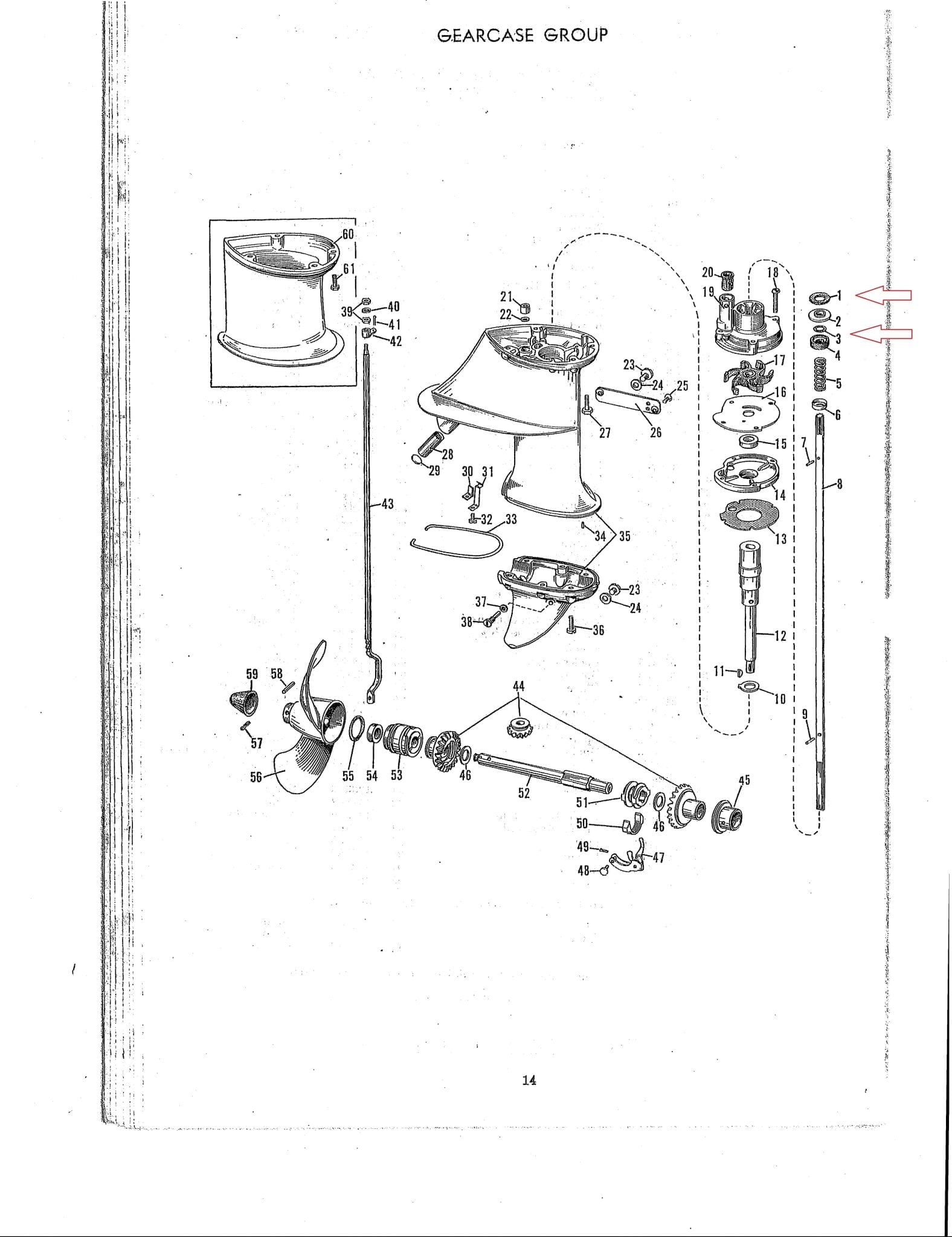

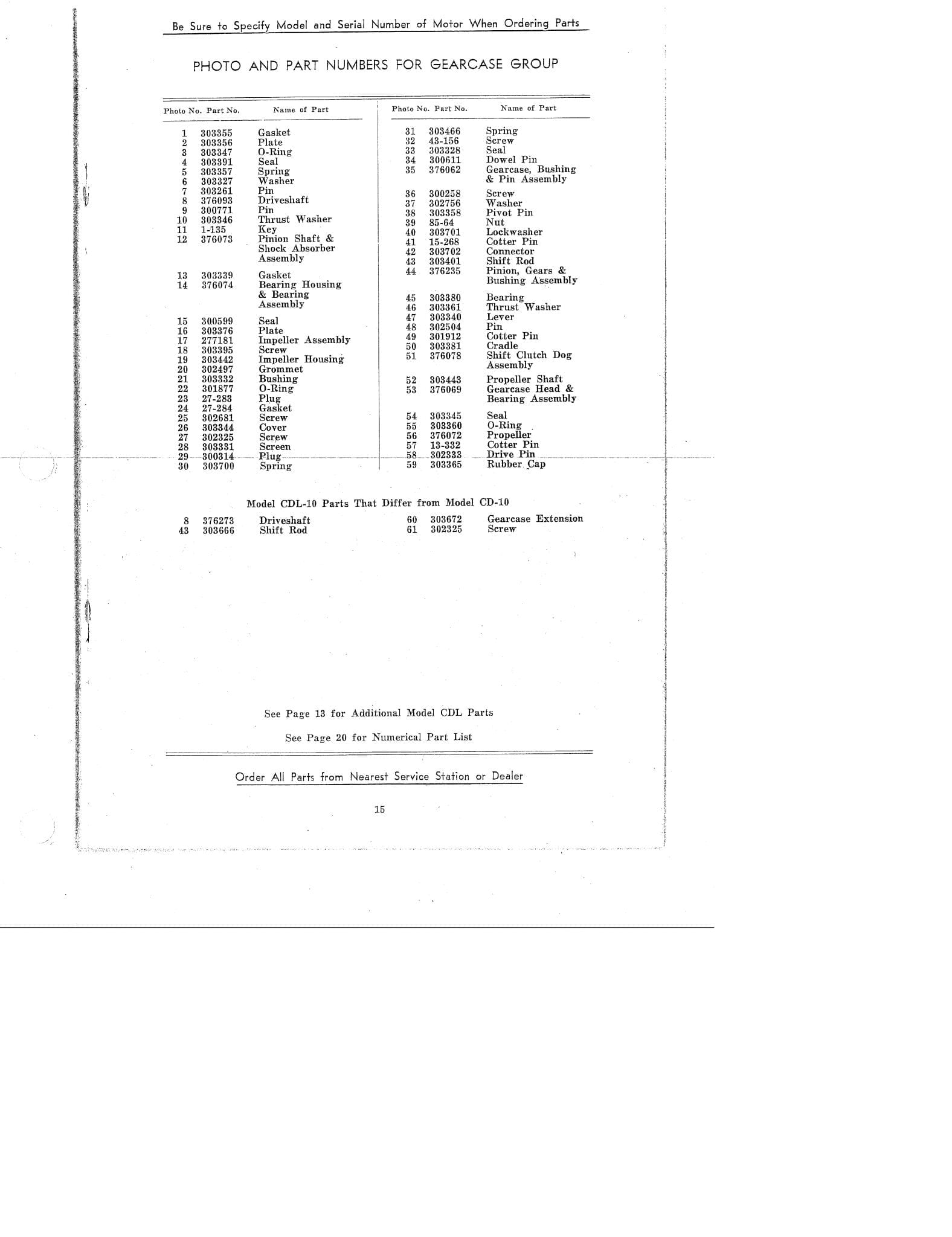

Change parts 1 and 3 in the Johnson CD 5.5hp lower unit/gear case diagram. I know its for 1954 CD 5.5, but the assembly and parts for that is the same. (Sorry I do not have a 1956 Johnson 7.5hp parts diagram to show.)

Parts to change

– lower crankcase seal

– o-ring

– power head to exhaust housing gasket***Make sure parts 1 through 7 are all present. If not you will not have a complete lower crankshaft seal.***

Here are excellent videos to show you how.

-

This reply was modified 3 years, 7 months ago by

cajuncook1.

-

This reply was modified 3 years, 7 months ago by

cajuncook1.

November 13, 2020 at 8:01 am #220753Thank you all so much! This is just the type of info I was looking for. I’ll get a parts list together and start ordering everything.

Regarding Frankr’s comment on the shock absorber, does that destroy any other parts of the lower unit if it fails?

November 13, 2020 at 10:55 am #220765Yes, often breaks the bearing plate under the water pump. You do not want that to happen

November 13, 2020 at 1:52 pm #220774Here is link to a discussion about the Johnson CD and AD Shock Absorber

https://www.aomci.org/forums/topic/johnson-cd-10-shock-absorber-question/

-

This reply was modified 3 years, 7 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.