Home › Forum › Ask A Member › 1958 10 hp Low speed carb bushing

- This topic has 4 replies, 4 voices, and was last updated 7 months, 2 weeks ago by

Don.

-

AuthorPosts

-

July 4, 2025 at 7:13 pm #297939

After being a member here for all of three years, I’m an expert, really. But OMC 10 hp motors are evil. For one thing, there is a bushing in the low speed jet hole (for some reason) that just spins in place when you try to seat the needle.

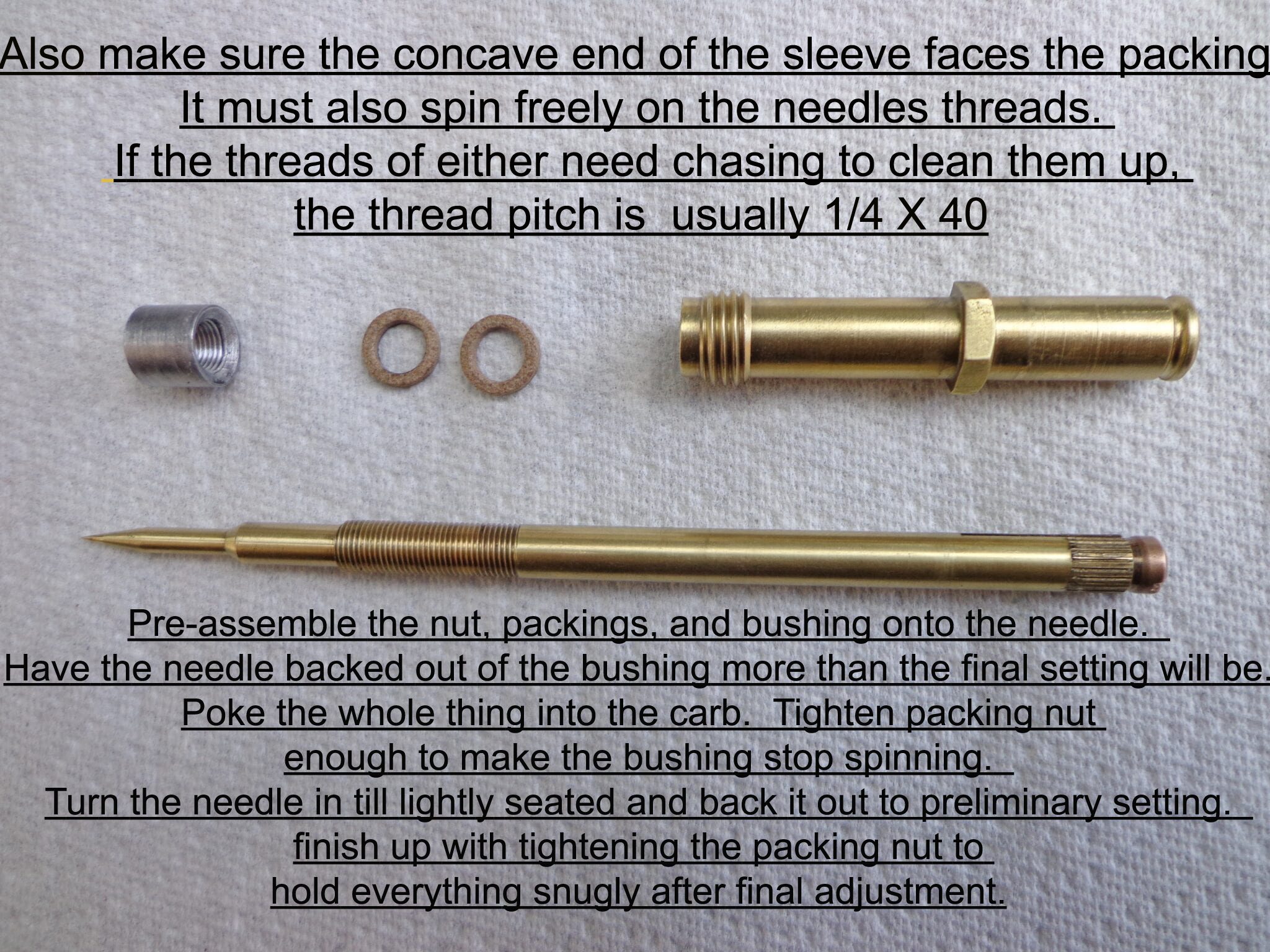

I have read somewhere here, I think, to carefully assemble the needle packings onto the low speed jet and then turn the bushing on a couple of threads, then insert the whole lot into the carb, tighten the packing nut just enough to keep the bushing from turning, tighten down the needle to it’s seat, back it off to the proper initial setting, then tighten the packing nut to fix it in place.

I have made several attempts. Got it to work once but had to undo the packing nut to install the air breather/silencer. Stopped working.

Has anyone ever just epoxied the thing in place?

Suggestions??

Thanks.

July 4, 2025 at 8:07 pm #297940If you haven’t already tried it, use 3 packing and the nylon washer that goes against the packing nut. That might allow you that little extra tightening to keep the bushing from turning. If it works, you don’t need to undo the nut to install the silencer. The hole is big enough in the silencer to fit over it.

July 4, 2025 at 8:22 pm #297941This picture is courtesy of various Members. Mumbles, Frank R , Fleetwin and probably a few more. I’m not certain who exactly is responsible for it.

The thread where it originally came from is here:

https://www.aomci.org/forums/topic/loose-low-speed-needle-bushing/

July 5, 2025 at 8:59 am #297950Thanks Steve D and seakaye 12. I’ll try the extra washer. The epoxy idea might work if there is such a thing as fuel proof epoxy. Thanks to

all the names that you mentioned over the photo. These names keep surfacing over and over on the “Ask a Member” page providing endless help.

Happy July 4

July 5, 2025 at 5:59 pm #297959This was Frank’s post. I would definitely remove the parts from the carb, oil up the threads and work the needle in and out of the darn bushing many times until it spins freely. Adding the extra packing washer, or perhaps one of the clear plastic ones from a newer carb kit will help.

I just wish I knew why these darn carbs are designed this way. Some sort of cost savings? Horrible design indeed. Send us a sign Frank!

-

AuthorPosts

- You must be logged in to reply to this topic.