Home › Forum › Ask A Member › 3Dprinting

- This topic has 17 replies, 14 voices, and was last updated 4 years, 7 months ago by

labrador-guy.

labrador-guy.

-

AuthorPosts

-

October 6, 2018 at 5:38 am #84054

Some folks use the plastic 3d printers to make molds to cast metal parts. If you have the broken piece, you stick it together as best you can , and the printer makes a facsimile out of plastic. They then make a lost wax mold with the plastic one.

September 3, 2019 at 8:57 pm #182567My son has done this. He had an old JohnsonRude with a throttle lever plate that was broken in half. He stuck the pieces together with glue, scanned the plate, printed it in PLA. PLA and some other plastics will burn away; he attached wax sprues to the print, invested all, burned out plastic and wax, and cast a new aluminum plate. It wasn’t perfect but was usable.

As a practical matter, this is not cost-effective if you’re looking to market whatever you reproduce. To do a small production run, you would want to make a master of the object, and cast multiples in greensand, the old cope-and-drag method.

Which begs the question: out of all of the years of all makes and models of outboards, what parts are consistently broken often enough to make going to that effort worthwhile?

September 4, 2019 at 6:00 am #182584Think parts like Koban battery ignition timer, or any RBM battery ignition timer..mag advance levers.

Currently in cahoots with another member to scan, 3D print, cast and machine some of these items… low quantity but for those that need the timer to complete a motor or replace their broken one. what would be the true value…time consuming, why yes but it should aid in getting more of these motors complete and hopefully back on a boat again…http://www.richardsoutboardtools.com

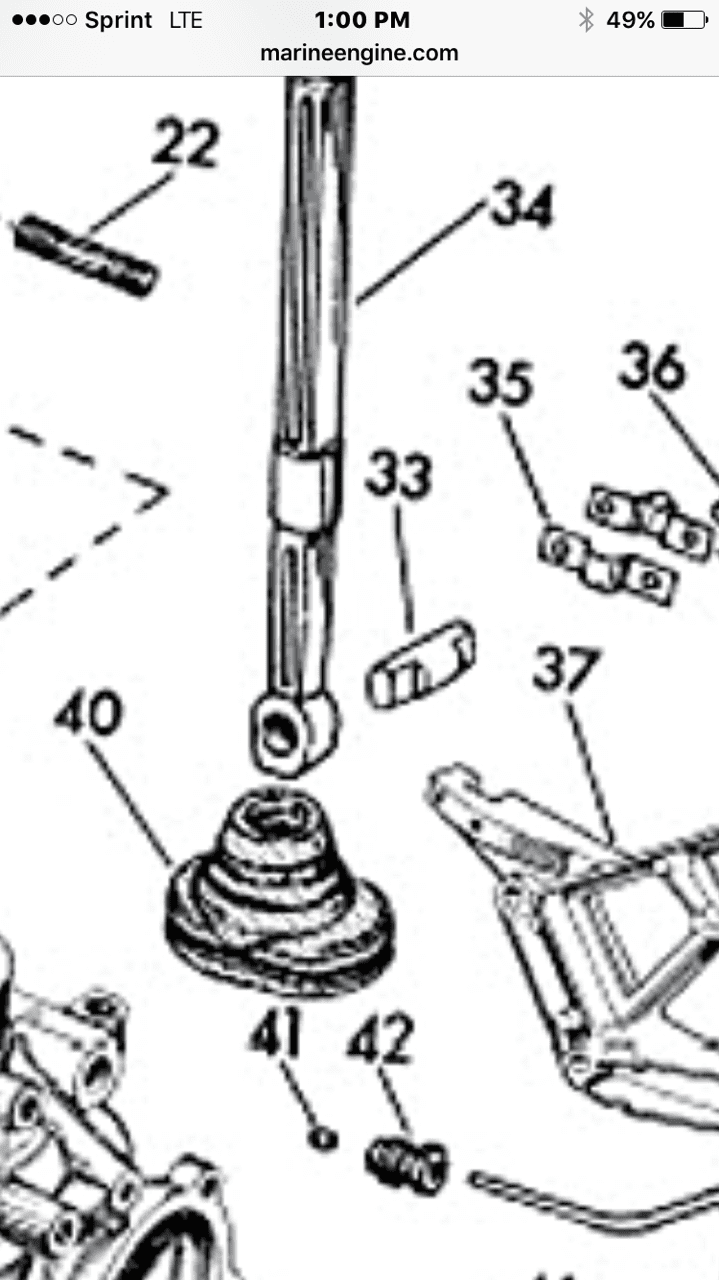

classicomctools@gmail.comSeptember 4, 2019 at 2:05 pm #182617September 4, 2019 at 2:33 pm #182621Tinman – I need that #33 throttle pin for my QD-20 restoration. Would you be willing to make one for me?

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."September 4, 2019 at 8:29 pm #182636September 4, 2019 at 8:43 pm #182642Tinman – sent you a PM response but had some trouble so hope you got it.

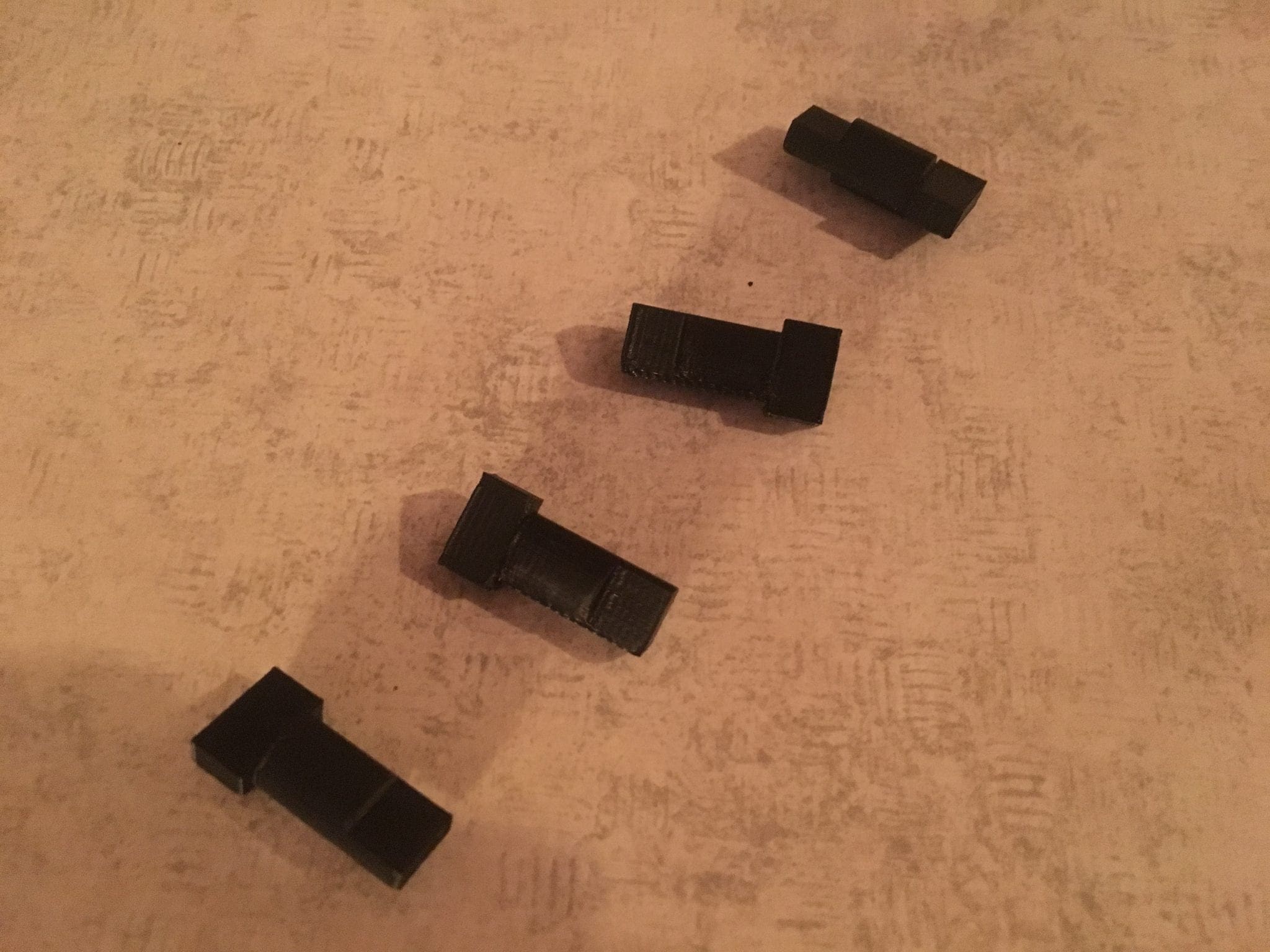

Pins and grip both look good.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."September 4, 2019 at 9:17 pm #182644That nylon cross piece can be made from the plastic bolts that hold down a toilet seat! Just takes a little grinding and whittling! Cut it to length with a hack saw. It’ll get ya going!

dale

-

AuthorPosts

- You must be logged in to reply to this topic.