Home › Forum › Ask A Member › 67 33HP Evinrude running very hot

- This topic has 33 replies, 7 voices, and was last updated 2 years, 5 months ago by

fleetwin.

-

AuthorPosts

-

July 27, 2023 at 6:35 am #278528

Don, went through the pump yesterday. Impeller plate, housing, and impeller all replaced during rebuild. Impeller was OEM. All impeller cover bolt threads were perfect. I have a new impeller on order to err on the side of caution.

Looked under the water bypass plate on the lower unit as per Franks suggestion, and there was no crack. All passage ways open.

As far a pump flow, it was flowing during this problem. Was it at 100%, I don’t really know, but I did put my hand under the discharge while the motor was running, and it felt red hot.

Question….since this is a new rebuild with new pistons, rings etc, do motors for any reason run hotter during breaking in? Just a thought?

One thing for sure, when I assemble and run the motor next year, I will have my digital thermometer so I’m not guessing on temperature.

Thanks again,

Bob DJuly 27, 2023 at 12:59 pm #278534OK, so there was at least some water flow when you checked it out. I would think that a freshly rebuilt powerhead might run a bit hotter as well, what fuel/oil mix were you using? Had you just decelerated from WOT back to idle when you checked it, or had you been idling along? All water pump parts were new and OEM, you might want to compare them to the old parts, just to make sure there is no manufacturing defects. I would run a tap down through those water pump threads in the gearcase just to make sure the screws weren’t bottoming prematurely for some reason. How about the impeller plate mating surface on the gearcase….Clean, flat, no erosion/corrosion issues? I would use a little to the OMC type M/847 sealer between the SS impeller plate and the gearcase housing as well. But don’t put any sealer between the impeller housing and SS impeller plate, this will ooze out into the impeller area and may hinder pump performance. Don’t forget to check that little air bleed hole in the top of the impeller housing as well. How about the water tube, does it appear to be bent due to previous mis-installations? You may want to gently insert the impeller housing and grommet up and into the water tube to make sure it does not have to be pushed up too far into the exhaust housing to fit/seal properly on the grommet. The impeller housing should be about flush with the gearcase mating surface on the exhaust housing when sufficiently connected/sealed to the water tube.

From what you said, it really doesn’t seem like the actual engine temp was high when you noticed the hot water/steam discharge. It is possible that if you had let the engine continue to idle for a moment or two the discharge temp would have come down and the steam would have disappeared. Do you remember trying this, or did you just look and check immediately after coming down off a high throttle setting?

The only other variable here is the exhaust housing, and other possible bleed offs to cool it. I am not that familiar with this exhaust housing, so don’t know, just wish I had another exhaust housing to rip apart and inspect.

July 27, 2023 at 10:34 pm #278575I have a comment on your problem. The top of the water pump housing needs to have water in it to work properly, I have had a couple of these motors that the water outlet was modified and all or most of the warm water was exiting the blow hole. My 18 would send steam out when I was moving slowly then when I would speed up it was OK. I pulled the power head and a PO had hogged out the water shoot with a rasp or something. I found a washer just the right size and tapped in the port so some water would be directed into the exhaust. I know clear as mud! You do need some water splashing around in that housing. That might keep it cooler.

dale

1 user thanked author for this post.

July 28, 2023 at 10:10 pm #278619Don, I was running 24 to 1 for the break in.

Was running at about 2700 RPM for about 6 miles when I came down to idle and noticed the steam.

I then let the engine idle for 10 minutes and the steam didn’t subside. Since the motor had less than 3 hours on it never had it up to 4500RPM. Maybe it needs revs to get the water pumping to it cool down?

Started the motor in a barrel the next day (high idle with test wheel) and the same problem. The motor was immediately hot. Discharge was hotter than the water in the barrel.

All water pump parts new, impeller, plate and housing. Small hole in housing was open.

Will run a tap down the mounting holes.

As I mentioned before, the actual block was hot, the exhaust cover wasn’t bad, the cylinder head ok, the lower unit under the head burning hot and the water steaming.

I just wanted to thank everybody for their suggestions and help (especially Don). We won’t have a definitive answer until I get the boat back in the water next year with a new impeller, and the ability to actually check the various parts with a digital temperature gauge.

Maybe as Frank said, these motors just tend to run hot.

Thanks again,

Bob DAugust 5, 2023 at 10:16 pm #278847Still thinking about why it was running hot and the exhaust stack was burning up.

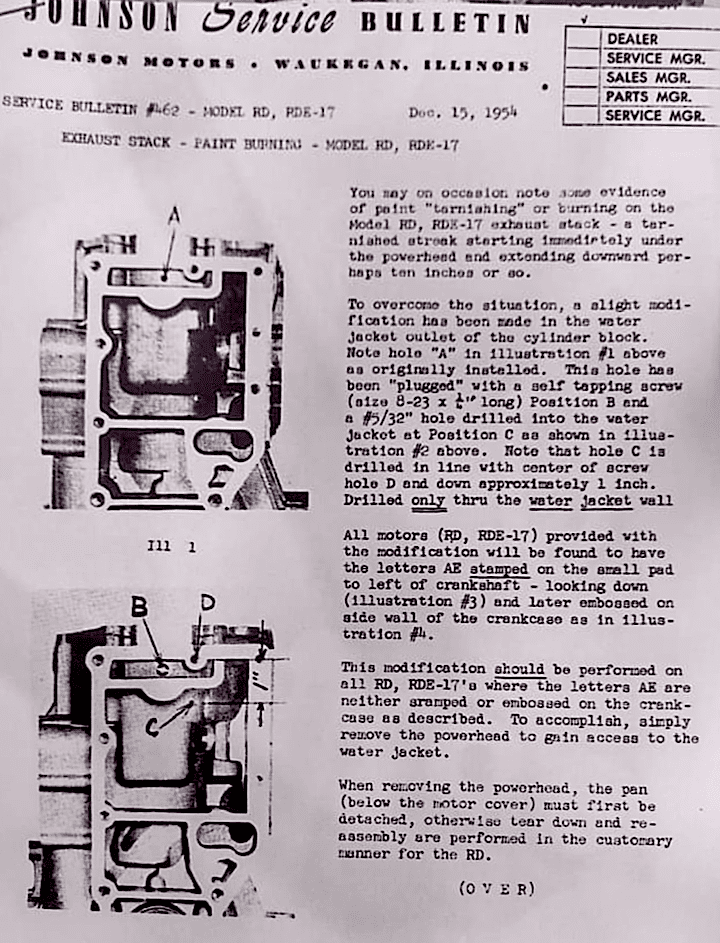

One of the members posted this service bulletin that he used on his 58 35HP Johnson on the AOMCI Facebook site.

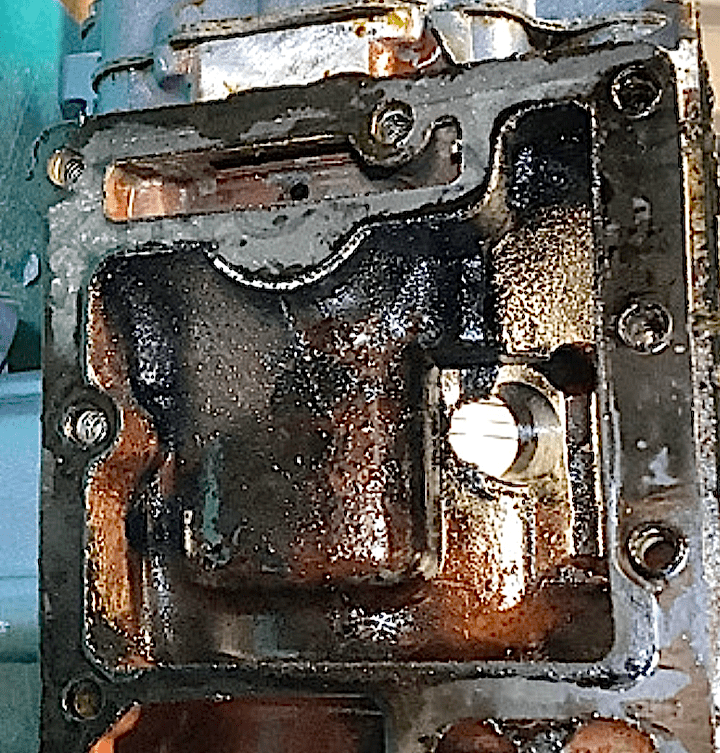

The head in the bulletin looks very similar to my 1967 33HP (picture below).

What does everyone think about giving this a try to eliminate my burning exhaust stack? I imagine I could reverse it if anything goes wrong?

Thanks,

Bob DAugust 6, 2023 at 5:32 pm #278886OK… Well I’m wondering if engines made after this period all had this cooling modification…. Are you sure there is not hole in that new spot already, perhaps just plugged with crud?

I gotta say though, that location really scares me though….Mighty close to those lower exhaust ports. Exhaust tuning is a tricky thing, one I surely don’t have a strong grasp on. I would just worry about that new hole pulling water back into those exhaust ports.

So, I’m gonna be conservative here.. If that hole isn’t there already, I don’t think I would add it…

August 6, 2023 at 7:08 pm #278893Ok Don, no modification.

I spent hours checking/ cleaning I’m positive there is no hole with crud. The picture posted was an old picture when I first pulled the head. It’s now spotless.

Have gone through all water passages on the head and gear case , with a hose simulating the water flow with the motor running , and everything was fine.

This is a tough one.

Thanks again,

Bob DAugust 7, 2023 at 6:32 am #278909Unfortunately, we may be searching for an issue that just isn’t there buddy… Although I’m not in favor of that modification you posted, I’m not against added some relief somewhere in that exhaust hsg to help cool it down a bit. Just wish I had one laying around here I could look at..

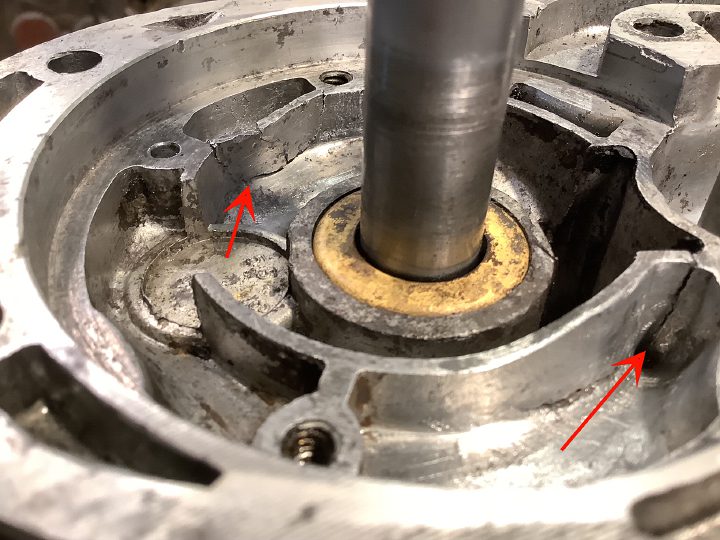

August 10, 2023 at 8:22 pm #279047Don, maybe this is the problem?

Dug around under the impeller plate more closely (something basic that I should have done a month ago !!!!!!), and found that previously, some ham fisted mechanic broke the gearcase on both sides when he installed a new seal.

I would think that this would disrupt some of the flow going into the pump? I was able to gently tap it back into shape,and will fill the broken walls and cracks with some JB Weld, or should I just look for a good replacement serviceable gear case?

Also when i changed the impeller when I got the motor last year I noticed I never sealed (Don’s good tips) the bottom of the plate with M/847 sealer.

Hopefully doing the above will help.

Thanks again,

Bob DAugust 11, 2023 at 3:01 am #279052AHA, now you are getting someplace. That is freeze damage, caused by expansion of ice. I’ll wager there is more cracking somewhere, letting air or exhaust leak into the intake side of the pump. Those are great water pumps, but lousy air pumps.

Mmmm……As I suggested back on July 23.

-

AuthorPosts

- You must be logged in to reply to this topic.