Home › Forum › Ask A Member › Almost home 55 cd12

- This topic has 5 replies, 4 voices, and was last updated 3 years, 8 months ago by

Steve Hegge.

-

AuthorPosts

-

October 19, 2021 at 1:15 pm #248346

Guys I’ve gotten great info from this group, need another question answered…ive replaced the water pump plate as mine was worn out with the new one suggested, yes expensive….and replace bearing head on prop shaft as it had a small crack under the o ring slot….new old stock was only 15.00….resized the shock… My next problem is the pin in the front of the bearing cap is gone. I have the oil channel but can’t seem to locate where the pin was in the bearing head, i see where it was on the skeg…can someone tell me where the oil slot goes I assume down to meet with the one in the skeg. I have no access to a machine shop to redrill and replace pin would rtv work

Any help will be appreciated a photo would be much appreciated almost doneOctober 19, 2021 at 4:42 pm #248351I am having a problem understanding your questions. Not sure what you are referring to when you refer to bearing head and resizing the shock and bearing cap and oil slot? Are you referring to the oil seal retainer and O ring?

October 20, 2021 at 9:26 am #248373Good morning, thanks for the reply sorry I was just going through the things done.

My question is i replaced the prop bearing head but when reassembling I found the pin that holds the inner bearing head in place is Shepard off I can see the it was in the bottom skeg but not in the bearing head.

I assume the bearing heads oil slot goes in in the down position and aligns with the one in the skeg housing. Is the pin a must can i use rtf black and hold the head in place

Thanks in advance for any info.October 20, 2021 at 12:14 pm #248390Surely the pin had a purpose in life … replace it with a same size piece

take out / drill out the broken piece and replace it with a same size/length drill shank or… a piece of SS rod

Joining AOMCI has priviledges 🙂

-

This reply was modified 3 years, 8 months ago by

crosbyman.

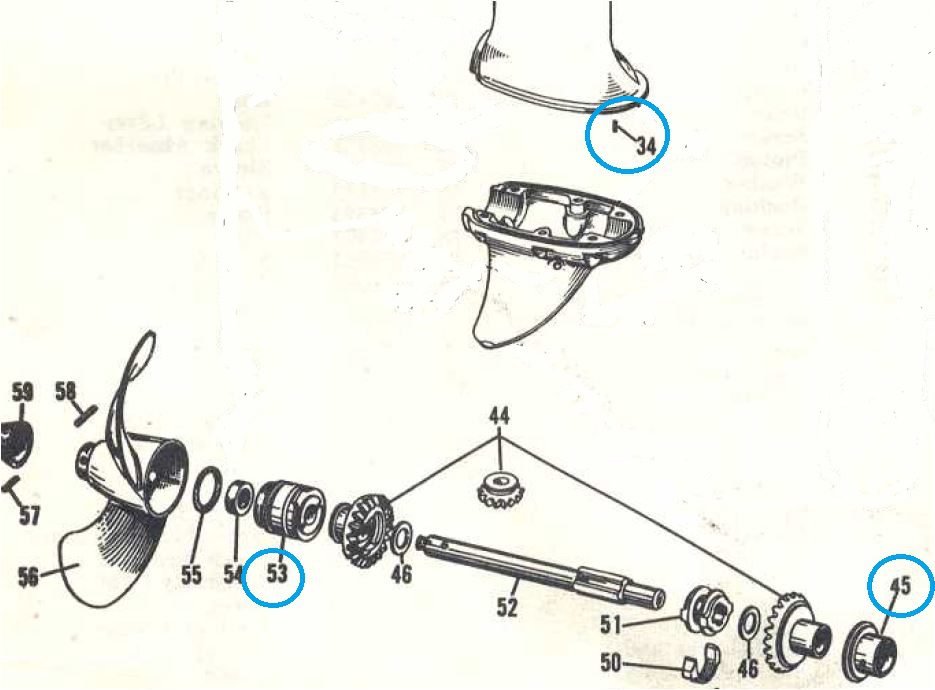

October 20, 2021 at 12:28 pm #248391The rear bearing carrier, #53, should have a tab cast into it which aligns with a slot in the exhaust housing to prevent it from turning. The front thrust bearing, #45, will have either a hole or a slot (can’t remember) to line up with the pin, #34, which is pressed into the exhaust housing. If the thrust bearing has a dimple or two on it, it means someone was in there earlier and never got it lined up correctly with the pin before tightening the skeg down. Quite often when this happens, the locating pin will get driven in flush with the housing and will have to be drilled out and replaced.

October 21, 2021 at 10:10 am #248426Thanks

just the info I needed. Might finish this yet. -

This reply was modified 3 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.