Home › Forum › Ask A Member › Aluminum brazing – Am I getting better?

- This topic has 11 replies, 8 voices, and was last updated 5 months, 4 weeks ago by

jeff-register.

-

AuthorPosts

-

January 7, 2025 at 8:29 pm #293203

I’m quiet pleased with how this came out. I have been struggling with this stuff for over 30 years. There is a lot the don’t tell you in there demonstrations. This is my best result. If I have this good a result next time I try to repair something with it, I guess I’m starting to figure it out. If not, I just got lucky this time. Tubs

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

January 8, 2025 at 1:21 pm #293221That’s some very impressive shaping and polishing. Nice job Tubs!

Improvise-Adapt-Overcome

January 8, 2025 at 6:17 pm #293227Nice Job! I always end up accidently melting out what I put in

before I’m done.Prepare to be boarded!

January 8, 2025 at 8:06 pm #293229Outstanding work!!

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."January 8, 2025 at 9:53 pm #293231Excellent work , Tubs. I assume that you are using the low temp zinc based rod. That stuff does make strong repairs. Working with it however takes some experience… all about cleanliness and heat control. It’s fun and inexpensive to learn the technique. For those that have not tried, pick up a couple of sticks and practice on scrap aluminum pieces. The skill , once learned will come in handy someday.

Joe B

January 9, 2025 at 10:42 am #293234Tubs, Ok, I’ll bite and answer the question….yes you are getting better at brazing.

No let me change that, you are getting great! Looks spectacular as always. When you feel you have perfected it 100% please do a write up if you could. I have been struggling for years trying to braze, and always get disgusted and quit.Tank came out looking good as well. Glad you liked the JB Weld trick.

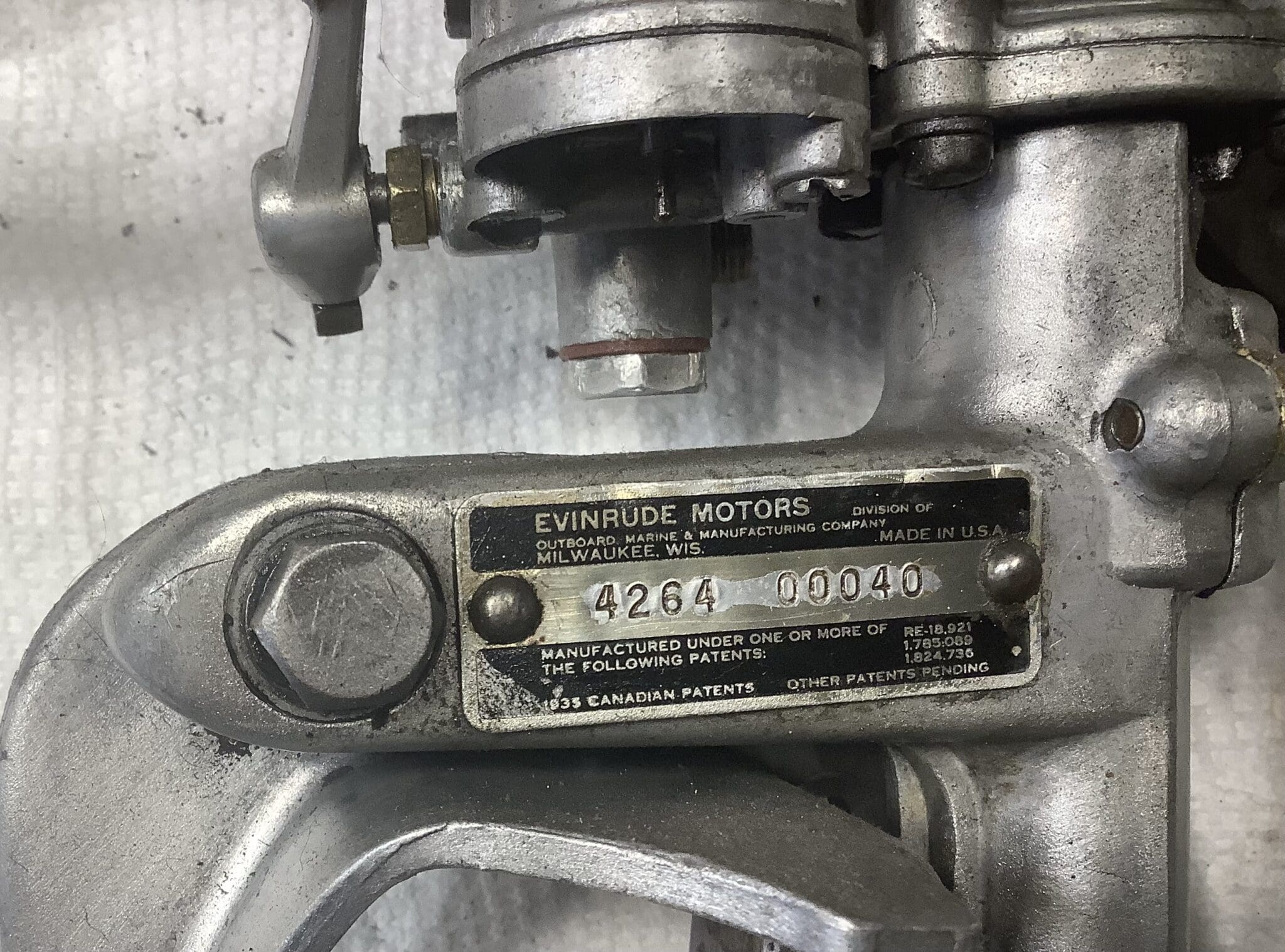

Have you looked at your powerhead yet? Even with new rings from Otto, my Cub runs great out of the water, but dies once in the test tank. Not the greatest compression in the world.On an unrelated Cub question??? Is your serial number 0021? If so, I think you take the oldest surviving Cub crown. I was running around feeling like the king at 0040 but will relinquish gracefully the crown if yours is 21.

Kinda cool, I guess these came out the door on the first day or so of production.? I wonder if they made 30-40 in a day?Bob D

1 user thanked author for this post.

January 10, 2025 at 10:21 am #293263

Bob, you’re still lowest on the S#. There were more numbers past the 21. As to your Cub. People think that the reason for the loss of compression is the ring seal to the cylinder. That is part of it. But not only where the ring contacts the cylinder but in the grooves of the piston. As the piston goes up and down, so does the ring. The clearance gets larger and if the groove is no longer parallel to the ring, the ring can rock. When a fresh motor warms up the ring end gap is only a few thousands. As the ring wears the end gap gets larger. This is the major loss of compression. If just the ring is worn, all you would have to do is replace it. However the cylinder is worn as well. If you take one old, or new ring, and check the ring end gap at the bottom of your cylinder, then push the ring close to the top, but not past where it runs, the difference in the end gap will give you a good idea of how much taper you have in your cylinder. I suspect your end gap will likely grow by .030 or more. While that will have an affect on the compression in a 2″ or 3″ cyl. bore, its huge in the 1-1/8″ bore of your Cub. My best guess as to why your motor wont run when put in water. I’m no where as confident in my abilities to use those brazing rods as you are. Tubs

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

1 user thanked author for this post.

January 10, 2025 at 3:17 pm #293275Tubs, you’re probably absolutely right concerning the pistons grooves. I was so happy just to get a set of rings, I thought I would be home free. I really didn’t check the clearances . I just slapped them in and it started.

It probably wouldn’t be able to push my 14’ Alumacraft anyway. My Pal struggles, and if there is a breeze with a chop, all bets are off. I do better with oars!

The tiny motors are fun conversation pieces. A bunch of teen girls on paddle boards floated by one day, and thought my Pal looked like a margarita mixer.

If anyone needs a coil for Cubs, the Mercury chainsaw coil conversion shown in The Antique Outboarder a while back also worked great for this motor.

Tubs when yours is back together I would love to know how it runs / compression numbers.

Thanks Bob D1 user thanked author for this post.

January 10, 2025 at 8:15 pm #293278

I doubt your piston is as bad as the one I posted. They make ring spacers to fill in the gap but I don’t know if you can get them that small. I suspect it is more the taper in the cylinder than worn piston ring groove. No solution there. I have a Mate that wont even run out of the water. I was 6 years old in 1952 when a friend of my grandfather took me out in his boat and let me run his 1937 Pal. When I was 11 he started let me use it through the summer’s till he passed. Everyone call it a egg beater but he never did. He would have to row over 2 miles if he wanted to fish the end of the lake until he got the motor. He never said anything but I could tell that motor was no joke to him. Tubs

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

January 10, 2025 at 8:46 pm #293281Consider low crankcase compression/ suction from worn bushings as a contributing factor to poor performance in these very small motors. This condition in conjunction with poor cylinder compression will render them near inop. New crank shaft bushings are an easier fix than a worn cylinder. … just might help.

Joe B

-

AuthorPosts

- You must be logged in to reply to this topic.