Home › Forum › Ask A Member › CD-12 Gearcase Re-Seal

- This topic has 9 replies, 4 voices, and was last updated 10 years, 3 months ago by

BRENT BERGEN.

-

AuthorPosts

-

March 16, 2015 at 9:34 pm #941

I have a Johnson CD-12 gearcase all apart and plan to replace all of the seals. The problem is that I am having a hard time sliding the ‘Gearcase Head and Bearing Assembly’ off of the Propshaft.

I think that the problem may be that the Shear Key receiver in the Propshaft may be a little distorted from prop impacts years ago, and this may be binding up the removal of the assembly.

If that is the problem, would it make sense to try to use valve grinding compound or fine sandpaper to remove any high spots on the propshaft?

Improvise-Adapt-Overcome

March 16, 2015 at 9:38 pm #12107I would think that would be ok, heck I, when first starting out used a file. my thinking was I am only hitting the high spots, and the prop rides there NOT a bearing or seal. Now I use a honing stone.

http://www.richardsoutboardtools.com

classicomctools@gmail.comMarch 17, 2015 at 12:23 pm #12170Thanks Richard.

I would greatly appreciate it if anyone has any helpful tips on resealing this gearcase up. I have the Permatex Anaerobic Sealant, and a seal kit.

Thanks

Improvise-Adapt-Overcome

March 17, 2015 at 6:10 pm #12191This is what I have …

March 18, 2015 at 4:47 pm #12255

March 18, 2015 at 4:47 pm #12255Thanks Garry. That certainly will help.

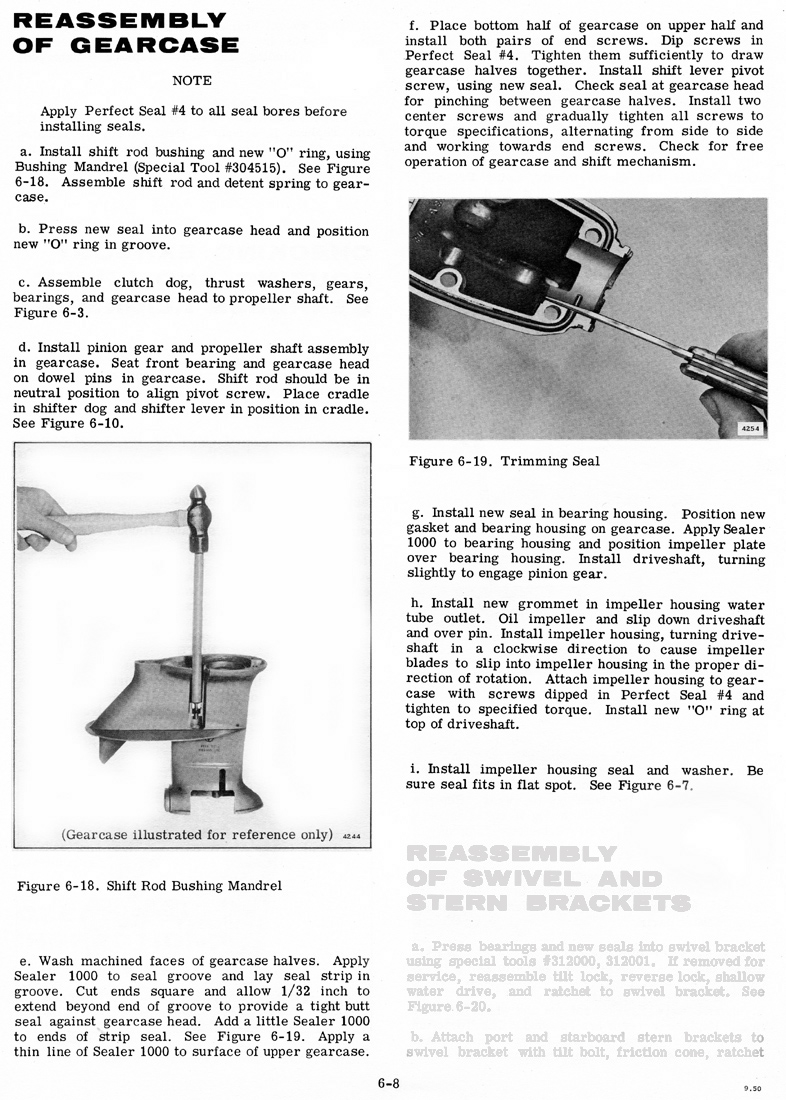

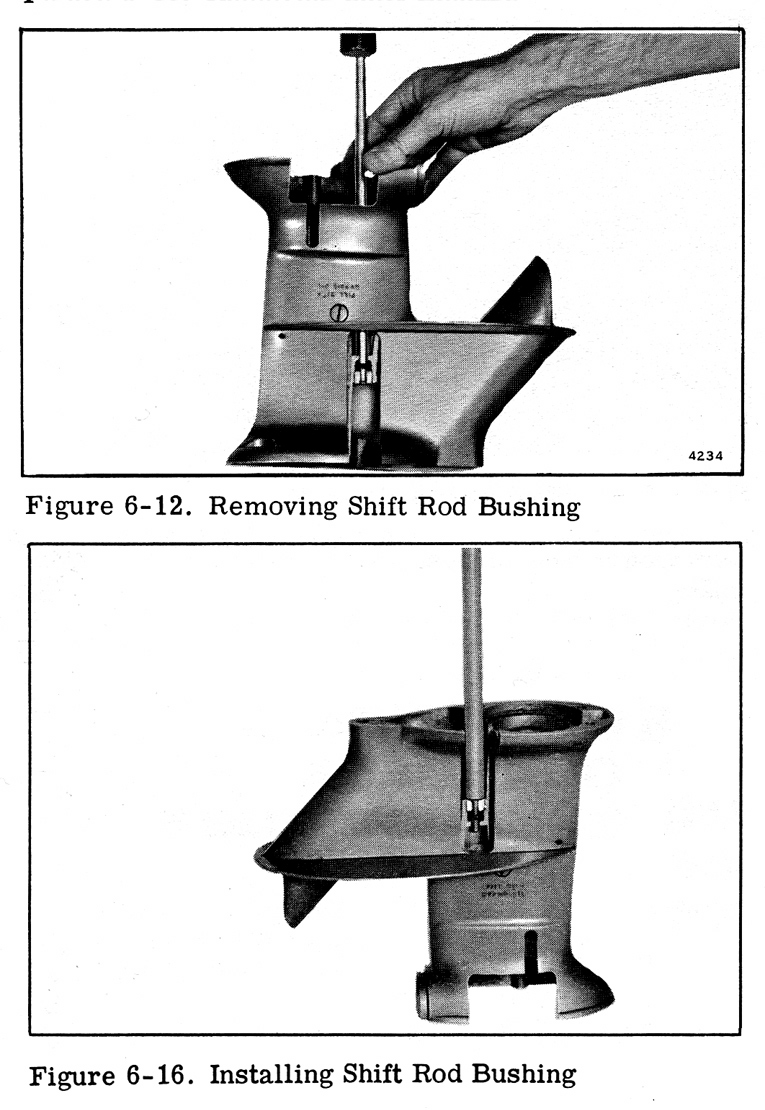

The only thing I’m unsure of now is the whole shift rod bushing and o-ring disassembly/reassembly, but I haven’t looked at that yet. Hopefully, that will become evident when I take a good look at it.

This motor also has a bound up shock absorber that I need to inspect. I see there is another thread on here about pressing them back to size and putting them back into service when the spring is not broken. 😀

Improvise-Adapt-Overcome

March 18, 2015 at 9:01 pm #12274Yes, the assembled length should be 6-11/16". The factory makes a special tool for pushing out the "O" ring retainer. Of course the shift rod must be removed.

Frank Robb makes a duplicate of this tool for those that can’t afford the factory price or where with all to make there own. The alternative is to tap threads into the top of the retainer and pull it out with a long machine screw.

. . . 🙂

March 18, 2015 at 9:42 pm #12277

March 18, 2015 at 9:42 pm #12277Since the shift rod is quarter inch rod, I made my tool out of 5/16" rod a foot long. Using an electric drill clamped to my work bench (Carefully so I didn’t crush the grip or obstruct any air cooling holes) I turned down one end (with an inch wide mill file) to the quarter inch diameter of the shift rod. That turned end of the rod used another piece of notched scrap lumber clamped to the bench as a steady rest. Then I threaded the drill motor end so I could screw on a nut which would act as a stop (after filing the corners off the nut and the protruding threads off the rod) when re=installing the "O" ring retainer.

I hope that explanation is not too confusing …

March 19, 2015 at 12:33 pm #12326

March 19, 2015 at 12:33 pm #12326Thank you Garry. I think I understand this now and it has been very educational for me. From another thread, it doesn’t sound as if Frank Robb makes the shift rod bushing tool anymore, but I can always ask him.

It looks as though the factory tool is larger in diameter than 5/16" on the ‘handle’ section probably to give it a little more contact area with the bushing and disperse the impact.

A lathe sure would be helpful for turning down some larger diameter stock. I may be calling on a machinist friend if I can’t get the tool from Frank.

Improvise-Adapt-Overcome

March 19, 2015 at 12:45 pm #12327Very few gearcases have a 5/16" diameter hole above the bushing. I found that out when somebody broke a gearcase by pounding a 5/16 rod through it anyway. As time went by, I found that the hole diameter actually varies all over the place, and I kept turning the diameter of my tool smaller and smaller to go through the smallest known hole. The last spec I used was still a few thou’s larger than the OMC factory tool. Ultimate result was that it got to where it didn’t work reliably. And the factory tool doesn’t work reliably either. So that’s why I stopped making them. You can read about an alternative way of removing the bushing at my website, http://www.franksoutboardtools.com

March 19, 2015 at 7:14 pm #12347Frank, thanks for the very informative explanation.

The alternative method looks like a good solution to me. I would just make sure that I have a NOS bushing on hand, and plan on replacing the old one.

Improvise-Adapt-Overcome

-

AuthorPosts

- You must be logged in to reply to this topic.