Home › Forum › Ask A Member › Chris Craft Challenger Gas Tank

- This topic has 8 replies, 2 voices, and was last updated 7 years, 10 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

June 27, 2016 at 9:18 pm #4602

Going to work on the Chris Craft Challenger 5 hp gas tank next.

I noticed that it’s cast aluminum, made in two halves, screwed

together, and evidently leaked at one time.

There’s four screws in the inner circle and a series of screws

on the outer perimmeter under the center band of the tank.

The outer screws all have some old putty of some kind over them

and the center band had been repainted a different color of blue,

so I know it’s leaked in the past.

The inside of the tank has a lot of aluminum powder / corrosion.

I shook & blew out what’s loose.

Anyone ever have one of these Chris Craft tanks apart?

Seeing how I know it’s leaked in the past and it would be easy to

sand blast the inside if it were apart, I’m tempted to do so, but

the little voice inside my head says that "This might be a bad idea"!

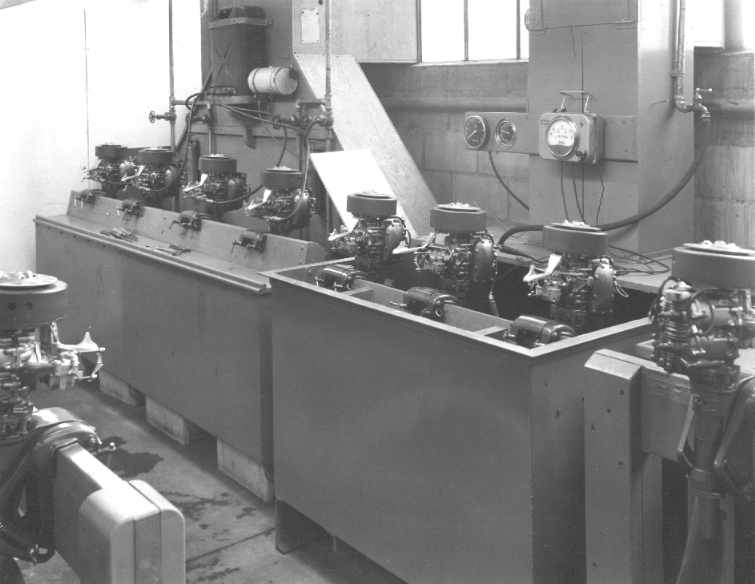

Any thoughts ? Bad idea? Good idea?Tank in photo is not mine, but same thing.

Prepare to be boarded!

June 27, 2016 at 9:25 pm #39068Yes, I have had mine apart. Nothing to worry about, just remove the screws to get it apart. It took some time, but I made a thin gasket for mine to seal it up. I can’t remember what I used for a sealer… I think it was Permatex #1. I believe they were originally sealed with the use of a sealing compound only.

I saw your question about the gearcase, but I did not go into mine, so couldn’t be of much help. otherwise I have been completely through mine. Be careful though, the Challenger is such an excellent running motor, you will then want a Commander! Both the Chris Craft models are excellent motors, and fun to operate!June 27, 2016 at 9:29 pm #39069June 27, 2016 at 9:30 pm #39070June 27, 2016 at 11:28 pm #39085Thanks Jerry for the vote of confidence in splitting the tank in two,

and for the great photos! I wonder what the best sealer would be

for putting the gas tank halves back together? Sure someone

has thoughts on that.

Already wishing I had that 10 hp Commander, lol.Prepare to be boarded!

June 28, 2016 at 10:34 am #39115I think if I were to do it over again, I would have used Gasoila sealer. It’s something OMC used on fittings, etc. Not sure how hard it would be to get apart in the future though. Or, you need something that’s fuel proof, since it will be in direct contact with gasoline. I f you decide to make a gasket, use some thin gasket paper, if you use thick stuff it will show after the tank is reassembled. The Challeger may well be the slowest idling motor I have ever seen. The only other motor I have that will go that low is my Martin ’45’. After I got my Challenger running I became an instant Chris Craft fan. Now I have two Commander’s to go with it. One is restored and one is a clean original.

June 28, 2016 at 11:19 pm #39172I’m glad I took the gas tank apart. Lost of powdery corrosion and chunks of

old sealer loose inside, that must have squeezed out of the joints when put

together last. After I sand blasted I see that I have lots of little pits in the bottom half,

and one pin hole that I could see light through.

There was no gasket between the halves. Should I bolt it up together good

and use gas tank sealer to seal the pin hole and the tank halves, or

seal the tank halves first with some kind of sealant, then use gas tank sealer

for the pin hole?Prepare to be boarded!

June 29, 2016 at 10:22 am #39214I think I would use the gas tank sealer while it’s in 2 pieces, then use a sealer [on the seam] when reassembling the two halves. My concern is getting the gas tank sealer [coating] around all the curves and crevices in the tank, that is if you put it together and pour in the sealer.. That way if it leaks, you can get it back apart if needed.

June 29, 2016 at 11:50 am #39219Jerry, I think I like your idea. Maybe I could tape off the flange areas,

then use a little foam brush to spread the gas tank sealer around.

Now I just have to decide on the flange sealer. Don’t have any Gasoila,

but will read about it.

Thanks!Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.