Home › Forum › Ask A Member › Elto Ace Flywheel removal

- This topic has 5 replies, 4 voices, and was last updated 4 years, 6 months ago by

garry-in-michigan.

garry-in-michigan.

-

AuthorPosts

-

October 22, 2019 at 10:32 pm #185765

Dumb question – how do you remove the flywheel on a 1940 elto ace? After removing the rope sheave there are no tapped holes for a wheel puller and there is not enough clearance to use the type of puller that grips the bottom edges of the flywheel. Hoping you all have some neat and easy trick for these. Thanks in advance for your help!

October 23, 2019 at 4:48 am #185768I believe the rope plate is the puller on those motors. Put the nut back on, then the plate. Loosen the flywheel nut and tighten it against the rope plate and it should pop off.

I like to tighten the nut against the plate, and then some light to medium rapid taps with a small brass hammer. Tighten the nut against he plate some more and repeat the rapid taps. It should pop off.October 23, 2019 at 10:27 am #185786.

-

This reply was modified 4 years, 6 months ago by

The Boat House.

The Boat House.

-

This reply was modified 4 years, 6 months ago by

The Boat House.

The Boat House.

-

This reply was modified 3 years, 2 months ago by

The Boat House.

The Boat House.

October 23, 2019 at 10:35 am #185789.

-

This reply was modified 3 years, 2 months ago by

The Boat House.

The Boat House.

October 23, 2019 at 10:57 am #185791Don’t even THINK of using the edge of the flywheel type puller’. They are known to distort the flywheel and in some cases pull off the major portion while leaving the hub attached. In the cases where there is no threaded holes a crankshaft “knocker” is used. This “Special tool” consists of a longer flywheel nut that is used to protect the end of the crankshaft. It uses the end play of the shaft to remove the flywheel. It screws down against the crank and you lift the flywheel while hitting the nut with a hammer. The factory tool bottoms against the taper and has the bottom diameter reduced to clear the flywheel. Some use the flywheel nut just loosened to the end of the crank. This can distort the threads if hit to hard. Many use two regular nuts held together with a short screw. Although it protects the top threads from damage, if not hit squarely, this can knock the threads off the crankshaft. It is important to lift the flywheel so the crank has some place to go. Otherwise the force will be against the crankshaft and may distort it and cause bearing problems.

-

This reply was modified 4 years, 6 months ago by

garry-in-michigan.

garry-in-michigan.

-

This reply was modified 4 years, 6 months ago by

garry-in-michigan.

garry-in-michigan.

-

This reply was modified 4 years, 6 months ago by

garry-in-michigan.

garry-in-michigan.

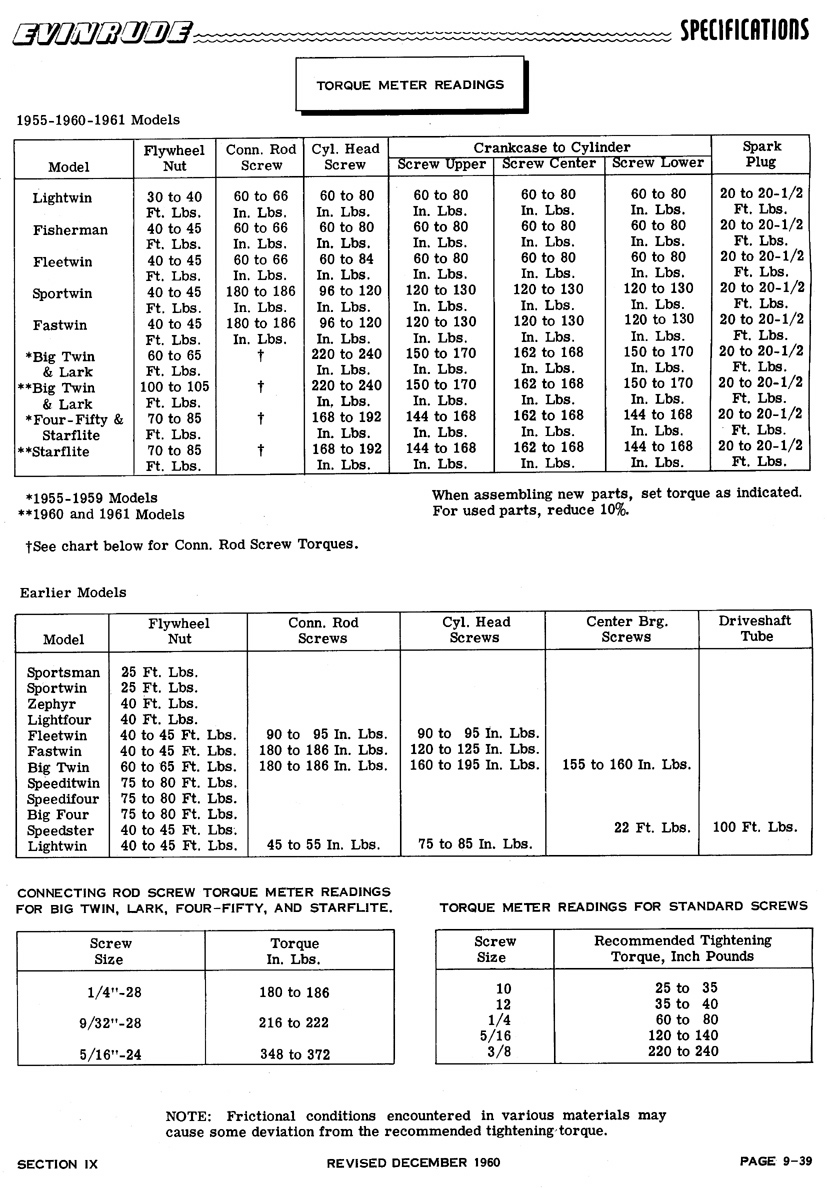

October 23, 2019 at 12:51 pm #185799P.S. In olden days, at the dawn of time before television, it was considered proper to beat on the wrench with a brass hammer to tighten the flywheel nut. (Brass was used to protect the wrench) Since Television. we now have torque wrenches. These have proven be much more reliable. (The Chinese have VERY high standards and all rejects are sent overseas) Here are some of our more modern standards . . .

Your Elto Ace flywheel nut would be 24 foot pounds.

-

This reply was modified 4 years, 6 months ago by

garry-in-michigan.

garry-in-michigan.

-

This reply was modified 4 years, 6 months ago by

garry-in-michigan.

garry-in-michigan.

1 user thanked author for this post.

-

This reply was modified 4 years, 6 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.