Home › Forum › Ask A Member › Evinrude 18 Water Flow Loss

- This topic has 6 replies, 5 voices, and was last updated 7 months, 4 weeks ago by

crosbyman.

-

AuthorPosts

-

September 21, 2024 at 3:43 pm #290986

18 hp Evinrude, model 18502S, serial E02834. Runs great for 1-2 mins then cooling water disappears and it starts to get hot.

New impeller, housing looks good. Removes t-stat to rule out. Pumps strong water until it gets up to temp—on boat and tank.

Head gasket not blown, neither piston or spark plug steam cleaned.

Leaves me with the exhaust baffle leak? Are these models prone to blowing gasket or corroding through plate? Or am I way off base on disappearing water?

Engine is very clean, fresh water, no burned paint or corrosion.

These 1960’s 18’s have always given me fits. I have two other donor motors that look to have suffered similar fate. One locked up and one butchered by previous owner trying to remove exhaust plate.

September 21, 2024 at 5:47 pm #290989I would suggest removing the lower unit and attaching a water source to the copper tube. I have a garden hose attachment that steps down to a section of fuel hose for that purpose. Monitor the water flow with the engine running for a few minutes and watch for the change. If no change then I would tend to think that the issue is at the impeller. If there is a change then you have isolated the issue to the powerhead or the base gasket area?

September 23, 2024 at 11:24 am #291038Hard to advise for sure. Is this engine new to you? Does it show signs of overheat damage in the past? Fresh or salt water usage? Does the engine show signs of previous work done (excess sealer/new gaskets)? The exhaust cover gaskets are usually not an issue for these engines, unless debris from a failed impeller are blocking water passages intermittently. If the engine has seen alot of salt water use, then aluminum eroding away/splitting off the cylinder sleeves is more of a concern.

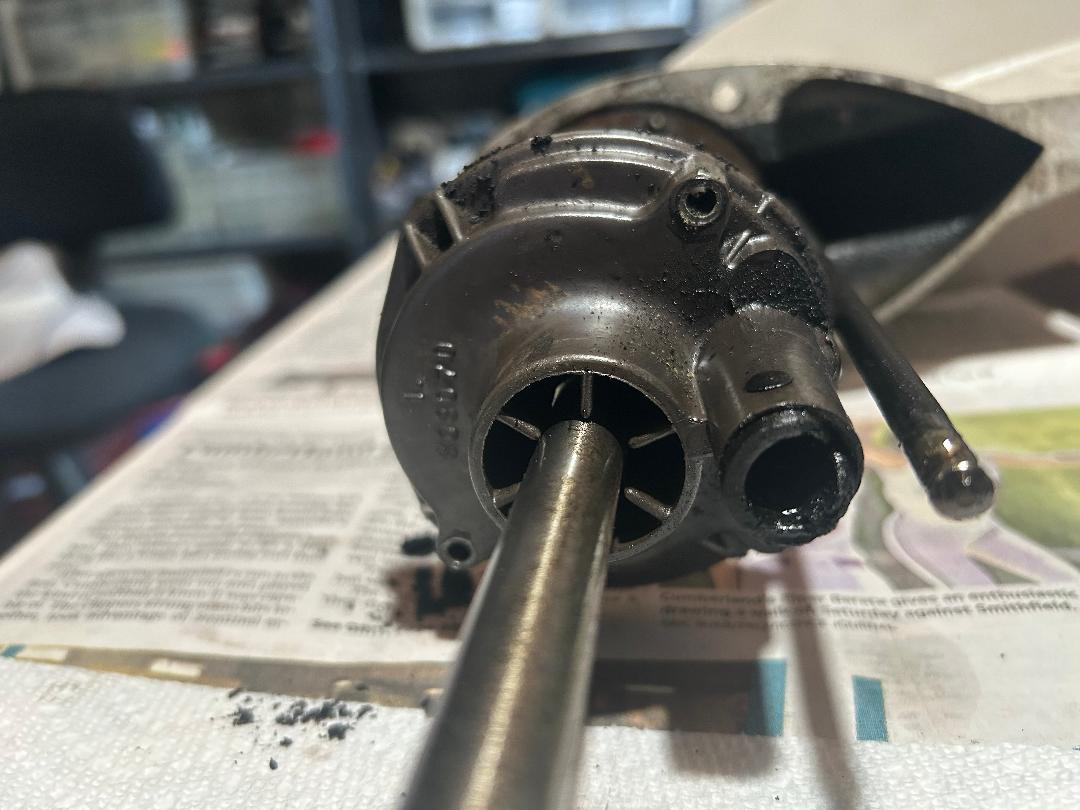

I guess I would start at the beginning. Are you sure the water pump is not an issue? Are you using OEM or aftermarket parts? Are you sure the threads on the water pump screws/holes are in good shape and clamping properly? Perhaps the tiny vent in the impeller housing is plugged up. Perhaps the aluminum under the SS impeller plate is worn/distorted/eroded creating an air leak into the water pump. Is the water tube in good shape, fitting properly into the impeller housing grommet? Oftentimes the water tubes get distorted/bent when misassembled. Once bent, they no longer fit securely/properly in the impeller housing water tube grommet. You could remove the impeller housing, slide it up inside the exhaust housing into the water tube, the bottom of the impeller housing should be pretty much “flush/even” with the mating surface of the exhaust housing. I guess the simplest thing to do here would be to try another “known good” gearcase/water pump assembly if you have one.

September 24, 2024 at 11:19 am #291064It’s an easy check to remove the thermostat cover and thermostat, then test run the motor briefly. At least you could verify that there is good flow to that point. The gearcase can be tested separately by immersing the gearcase in a bucket of water to just cover the impeller housing, then spinning the driveshaft with a drill and observing the flow from the impeller housing. It’s just a matter of systematically eliminating possibilities of a blockage or impedance of the water flow.

Fleetwin has the right advice. “I guess I would start at the beginning.”

Recently, I worked on a 1963 Johnson 18 hp that had two problems “at the beginning”. The impeller was pulverized to the point that the exit chamber in the impeller housing was 100% clogged with tiny pieces of impeller. In addition, the water tube grommet was folded back into the impeller housing blocking off a lot of the flow.

Improvise-Adapt-Overcome

November 11, 2024 at 2:51 pm #292044I have seen the intake screen behind the prop be full of sediment. This is very hard to see. Then the motor only gets water through the tiny holes in the bypass cover, which will be ok at idle for a few minutes. Something to think about.

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

November 12, 2024 at 7:05 pm #292068I have seen the intake screen behind the prop be full of sediment. This is very hard to see. Then the motor only gets water through the tiny holes in the bypass cover, which will be ok at idle for a few minutes. Something to think about.

Great advice, especially if you are running it in a barrel with dirty/oily water and debris such as leaves/pine needles. The inside looks OK, so doubt you have an issue with water leaking in from the exhaust cover…

November 13, 2024 at 8:21 am #292078most of the water does not even travel via the thermostat so it should always pee.

if it stops after getting to running temp the water pump would not know anyway so I suspect a powerhead area problem and not getting anywhere I would pull the head and inspect for something blocking the water passages. run air pressure backwards from pee hole and thermostat water inlet . pull the exhaust cover to inspect

just in case….the water flow diagram shows both the cold and “cyl warmed up” water exiting the thermostat mixing together when the running temp is reached . the mix gets dumped out

the common area for both cold and hot being the thermostat cavity and if BOTH cold and hot water suddenly stop flowing out and down ……..check to make certain the “thermostats area” isn’t causing the problem..even if you pulled the thermostat to test .

try to run some mono line in all water passages you can reach

Joining AOMCI has priviledges 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.