Home › Forum › Ask A Member › have you ever rebuilt this fuel pump?

- This topic has 14 replies, 7 voices, and was last updated 4 years, 2 months ago by

outboardnut.

outboardnut.

-

AuthorPosts

-

April 10, 2021 at 8:11 am #236018

From what I know there are no rebuild kits for this pump.

I plan to use it on a Johnson 25 hp 1955 RDE-17.

I was planning on finding one at Tomahawk

I figure all I would have to do is find the correct thickness neoprene and I would be set.

But of course making nice holes for the screws may be a problem.

What are your thoughts?April 10, 2021 at 11:41 pm #236129For making holes in gaskets I have a selection of old paper punches. If the material is thin you can sandwich it in between some heavy paper or thin cardboard. You could also clamp it between the pump housing halfs and run a sharp drill through the holes.

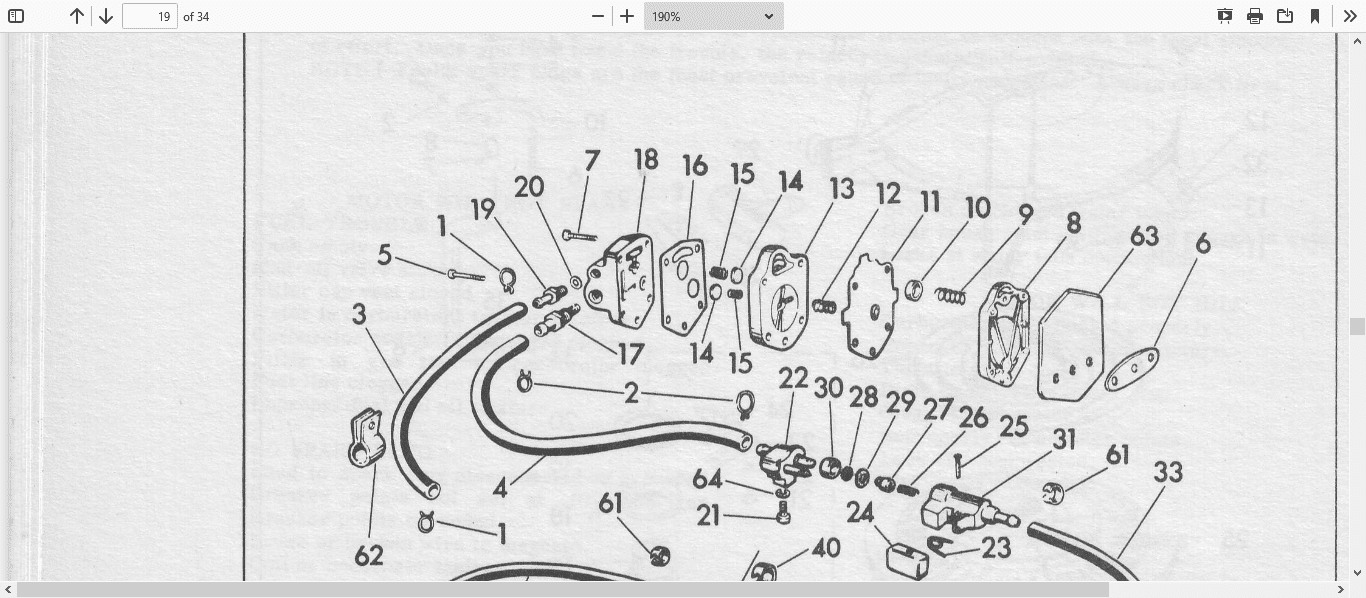

April 14, 2021 at 10:10 pm #236392While I have yet to actually rebuild one of these pumps, I have given it considerable thought on how I would do it. The original diaphragm (#11 in the diagram) is actually two sheets of material with a brass rivet holding the two sheets together. Spring (#12) rides against the rounded head of the rivet so it does not wear through the diaphragm material. I guess you could find a modern equivalent of that brass rivet but I’m not sure how well it would work.

My plan when I do this project will be to use a single sheet of diaphragm material and separate the brass rivet from the old diaphragm and then solder it to the spring (#12) so there is a smooth surface riding against the new diaphragm.

Knock on wood, I personally have not yet found one of these fuel pumps in non functional condition, and I’ve been through over a dozen of this style. They all seem to pump just fine and I use regular ethanol pump fuel but I always run the motor dry before storage and keep the fuel fresh.

The holes for the screws don’t have to be as perfect as you think, as long as the gasket openings where air and fuel are moving through are pretty precise, just take a big needle and poke a hole through for the screws and call it good.

April 15, 2021 at 12:48 pm #236416think this might fit …

Joining AOMCI has priviledges 🙂

April 16, 2021 at 7:46 pm #236494crosbyman-what did you try to post?

April 17, 2021 at 12:59 am #236515similar fuel pump replacement… does it not show up ??

not original but if it works….

Joining AOMCI has priviledges 🙂

-

This reply was modified 4 years, 2 months ago by

crosbyman.

April 17, 2021 at 7:44 am #236521On my screen your post is blank

“kindle We’re sorry. This preview is unavailable.”April 17, 2021 at 7:57 am #236522here is a screen capture… strange it shows up on mine

Joining AOMCI has priviledges 🙂

April 17, 2021 at 8:57 am #236524Blank on mine

April 17, 2021 at 12:19 pm #236531well… we had lots of spoofing before… now it is blanks ?? mine shows up fine

how the the screen shot come out… blank also ??

Joining AOMCI has priviledges 🙂

-

This reply was modified 4 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.