Home › Forum › Ask A Member › If I have a wiring error, I simply can’t find it…UPDATE: FIXED!

- This topic has 53 replies, 11 voices, and was last updated 6 years ago by

fleetwin.

-

AuthorPosts

-

February 14, 2018 at 3:44 pm #71049

We have all been here, that is for sure…At this point, don’t argue with success…

February 14, 2018 at 4:56 pm #71050I am due for a crow meal myself 😆

Joining AOMCI has priviledges 🙂

February 14, 2018 at 5:34 pm #71052I would suspect a broken wire inside the insulation.

As the wire position changes contact is made or broken.February 14, 2018 at 6:44 pm #71054All new wire throughout. This engine was a gut-job.

February 14, 2018 at 8:40 pm #71056Bought a brand new Painless wiring harness for a

car I was building. 2 days trying to figure out why

one tail light wouldn’t work. Finley just started

cutting a foot of wire at a time till I got power.

Broken wire inside the insulation. February 14, 2018 at 11:08 pm #71069

February 14, 2018 at 11:08 pm #71069Wiring harnesses can make you pull your hair out. I remember years ago working on a Mercruiser 496. It was new at the time, and had intermittant warning horns sounding while underway.. After replacing a few parts, the same service code would continue to be logged. Finally, I unplugged every single Deutsch connector on that engine, looked them over, then plugged em all back in. It never malfunctioned again!

February 15, 2018 at 12:33 am #71070I made the harnesses. Everything rings out perfectly.

I, too, have had bad luck with cheap, pre-made, offshore harnesses. Never again.

February 15, 2018 at 1:44 am #71071Those things remind me of the time our plant maintenance man was wiring a machine to the three phase bus overhead, with 3 (4 ?-whatever) conductor cable. As soon as he plugged it in, BAM, it threw the breaker. It took him more than a little while to notice a small bulge in the middle of the cable. Doing a bit of surgery on the cable,he found all of the conductors bared and twisted together, then covered with the rubber like the rest of the cable. I guess that was some guy’s idea of a joke at the cable factory.

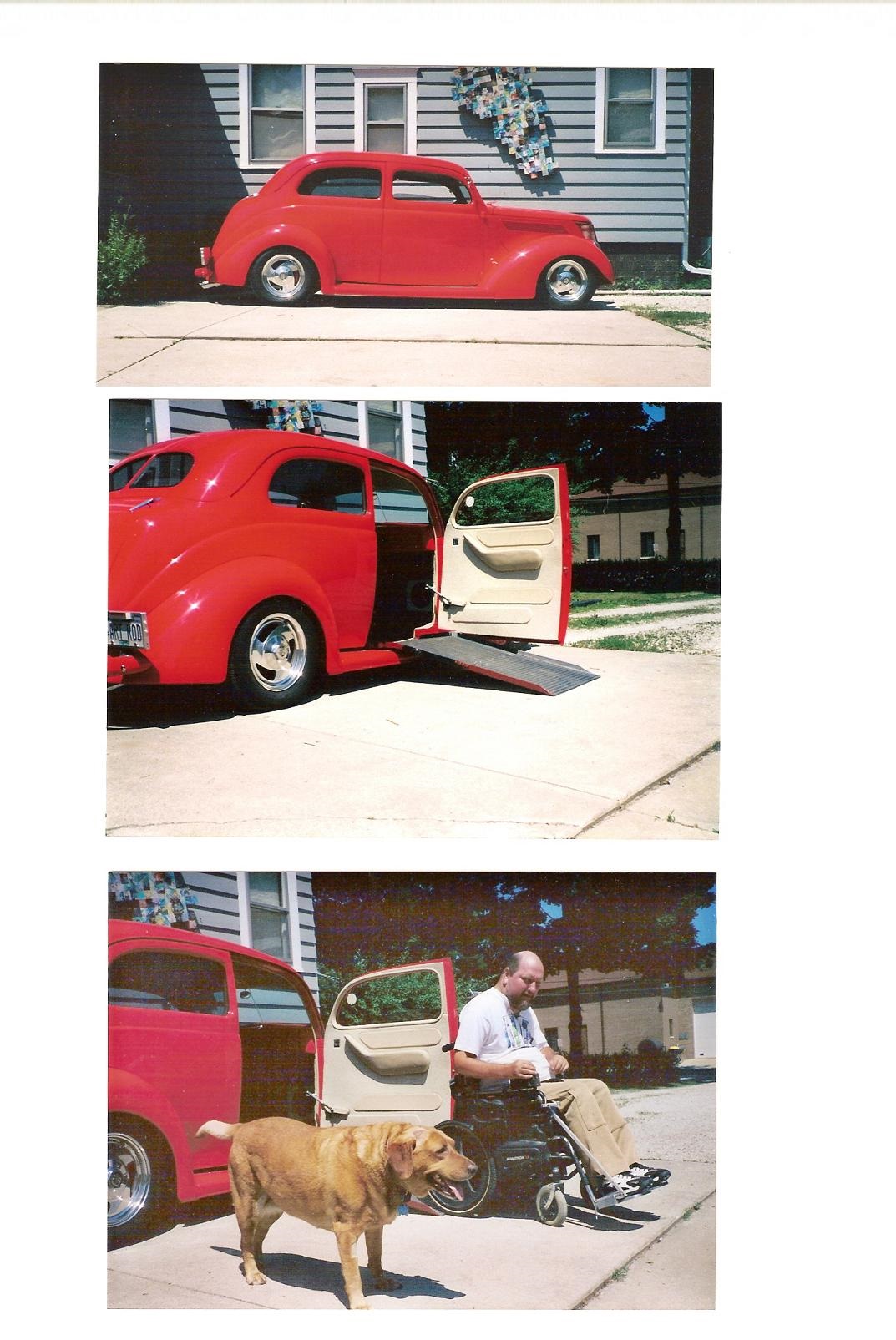

February 15, 2018 at 5:06 pm #71079I have put in a fair amount of wiring harnesses over the years. I don’t remember exactly how I got in on this project or why Greg decided he wanted a hot rod. One guy built the frame. Another did body and paint. I did the wiring. The motor is a front wheel drive Ford Taurus that’s in the trunk. The center of the frame was cut out and a steel plate is welded to the bottom outer frame rails so the floor is totally flat. No room for a drive shaft. The outer frame rail where the ramp is located is notched so he has enough head room to get in and out. The door and ramp are operated with a remote, buttons in the rear bumper, and controls on dash board. There is a latch on his chair that holds it in the car and he drives using all hand controls. I got the wiring harness in the car but one circuit was dead. I cut the wire all the way back to the fuse panel but got nothing. Had to pull the panel back out. Found the fuse only had one wire going to it. The other was installed on a open circuit. I had to scratch wire all the ramp and door stuff but that what you did before they sold these kits.

When he brought it to a show or cruse he put the ramp up and the door closed. It was fun to watch people come up to the car and when they look inside you here something like

“ Where are the seats?”He tried to buy a new ramp but the people who deal in these things would only sell to companies that do van conversions. He got on the phone and told this to some of his wheel chair buddies. A brand new ramp was delivered to his house. Never received a bill and no clue as to who, how, or why. He passed away last year.

April 15, 2018 at 8:59 pm #74068Problem found! So I figured I’d circle back on this old thread of mine.

To recap: My "kill" switch wasn’t killing….there’s still sparking on one of the cylinders. Many of you said "wiring issue" and I, perhaps a bit stubbornly, said that everything "rang out" with my meter, so I discounted the advice given. But it was true: My meter said that everything was fine.

Yesterday was the first warm spring day we’ve had all year, and even though the kill switch wasn’t resolved, I was eager to bucket test the engine to see if my engine building efforts have been worthwhile. So, bucket full of water, I fired it up. It started & ran pretty good, but not great…..and it seemed a wee little bit "shaky". Not smooth. (And the kill switch didn’t kill the engine, either)

Fuel supply seemed good. Air / carb…good. Whatever was causing the rough running had to be in the ignition. So for the umpteenth time, I pulled the flywheel and immediately had a "Eureka" moment: I had routed the kill wire on the top-cylinder points in such a way that it was making contact with the magnet hubs of the flywheel, and the flywheel had rubbed through the insulation. The exposed copper wire was making & breaking contact with the flywheel as it spun, grounding out & simulating point closure at the wrong time.

Today I replaced both kill wires, re-installed the points, caps & coils, and reassembled the whole thing. (Re)set the timing and reinstalled the flywheel & recoil. Everything rings out, sparks are strong and the kill switch now works properly.

Lessons learned: 1.) continuity on a meter doesn’t mean "everything is right" and 2.) don’t be so arrogant to believe that everything is right, especially when others repeatedly tell me "you have a wiring issue".

Now I just need another warm day to do another bucket test. I’m pretty sure this baby’s gonna hum!

-

AuthorPosts

- You must be logged in to reply to this topic.