Home › Forum › Ask A Member › Johnson HD25 Crankcase Leak

- This topic has 9 replies, 4 voices, and was last updated 4 years ago by

Tom Taylor.

-

AuthorPosts

-

April 15, 2020 at 10:23 pm #200128

Pretty far along in a Johnson HD25 refurbish and have it running fine in a tank. Only problem is that I’m seeing small leaks all around the crankcase-cylinder block joint. When assembling I cleaned both faces well (I thought), and power head was in good shape overall so I didn’t lap the surfaces or anything. Since it is now leaking all around I assume it is an assembly problem. The service manual stresses a THIN coat of cement for this interface, but maybe I got it too thin or using the wrong cement? Any suggestions on what cement I should be using here? Also…I didn’t measure torque on the screws, but just “dang tight”. Any and all advice is welcome!

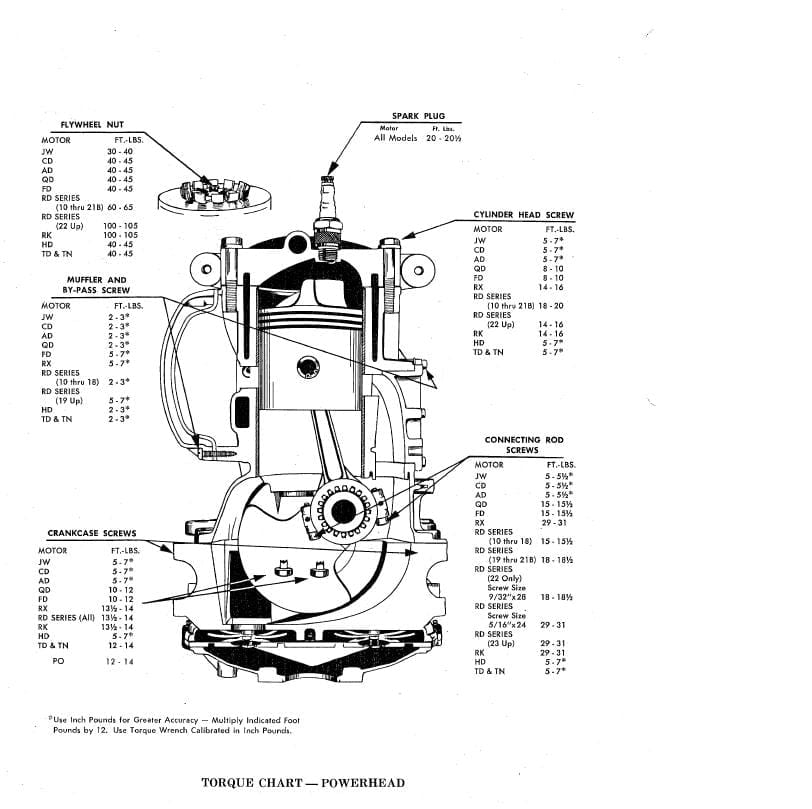

April 16, 2020 at 12:04 am #200132how about torquing to spec if not to late ??

Joining AOMCI has priviledges 🙂

-

This reply was modified 4 years ago by

Mumbles.

Mumbles.

April 16, 2020 at 5:17 pm #200181Thanks for the info! I’m gonna try that next.

April 16, 2020 at 7:59 pm #200200Try using Permatex Anaerobic Flange Sealant, P/N 51531, on it.

April 17, 2020 at 7:06 am #200239Here’s another vote for the Permatex 51531.

It may be best to take the powerhead apart again. If the wrong sealant was used, additional torque may not work. What sealant was used? The sealant itself could be the problem. There are only a few on the market that are suitable for use on crankcase halves.

April 17, 2020 at 11:19 am #200255Well…I used J-B Weld Super Weld, which doesn’t sound anything like the Permatex mentioned above. I will take it back down and make sure of the sealant this time, as well as the torque.

Thanks all for the specs, links and advice!April 17, 2020 at 11:32 am #200265Curiosity is killing me but where did you get the idea from to use epoxy as a sealer?

April 17, 2020 at 12:08 pm #200271Ha! It’s that strong combination of inexperience and misinterpretation. The Service Manual says “cement” which didn’t sound like sealer, so there ya go. In any case, I’m thrilled the thing is actually running. If I can go back and correct a few of the mistakes, all the better.

April 17, 2020 at 1:59 pm #200279You may need to heat it just to get the crankcase apart being that it’s epoxied together now. Once apart, gentle heating with a propane torch works wonders for removing JB Weld so it should be helpful cleaning up the mating surfaces. Plastic razorblades are good for scraping the mating surfaces without scratching them. Be patient, and whatever you do don’t lap the mating surfaces. Good luck!

April 17, 2020 at 2:32 pm #200283Many thanks!

-

This reply was modified 4 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.