Home › Forum › Ask A Member › Lu 1955 evinrude 7.5hp

- This topic has 5 replies, 5 voices, and was last updated 5 years, 4 months ago by

frankr.

frankr.

-

AuthorPosts

-

December 27, 2018 at 7:19 pm #161302

Is this normal for the drive shaft? If not can I simply pound back down somehow?

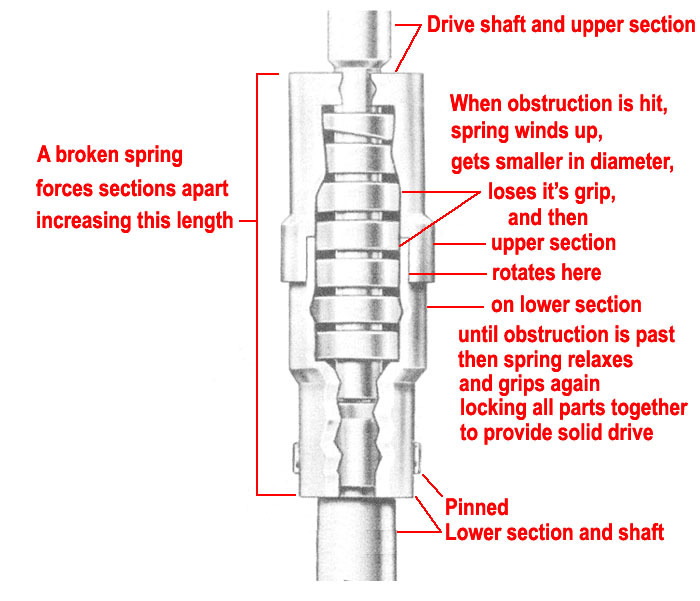

December 27, 2018 at 8:23 pm #161305The spring clutch was notorious in those 5.5 and 7.5 horse OMC outboards for the clutch spring breaking and/or creeping up to bind against the upper casting that holds the bearing and seal under the water pump. It helps to twist the shaft as you push it back together. Later models eliminated that clutch by using a propeller with a rubber hub that would absorb shock and slip when the prop got jammed. Some disgusted owners welded them together and then used a brass shear pin for safety. . .

-

This reply was modified 5 years, 4 months ago by

garry-in-michigan.

garry-in-michigan.

January 4, 2019 at 4:03 pm #161934When i find them aprung or broken, I squeeze them back together and weld them. Disgusted is an appropriate term. I also use the brass shear pin. I do not remember the original length specification. I have welded several of them though.

-BenOldJohnnyRude on YouTube

January 5, 2019 at 6:39 am #161951If the spring is not broken, I have had luck by pressing the shock back to exactly 6-11/16″, and putting it back in service. If the spring is broken, you still need to press it to length before welding.

I took a look at the posted pictures, and can’t find anything obviously wrong. Try to get a good linear measurement and see what you have there. If it is “sprung” then clean it up, and look inside with a high intensity flashlight to check for a break.

Other signs of a broken or “sprung” spring will be “bluing” or darkening at the top of the shock from heat and friction with the bearing and its housing. The bearing and housing may also be flared out from heat and friction at the point of contact. It is that friction that makes the motor wicked hard to rope over when assembled.

Hopefully, yours measures to spec, and the problem is solved.

January 5, 2019 at 7:19 am #161956Whether the spring is broken or just sprung, the shock will need to be pressed to exactly 6 11/16″ long. I took a look at the posted pictures, and don’t see anything obviously wrong. Get a good linear measurement and see what you have there.

If the measurement is greater than 6 11/16″ then clean up the inside and inspect it with a high intensity flashlight for a break. If it’s broken, then it must be welded. If it’s not broken, then I have had luck just pressing them back to spec, and putting them back in service. Opinions will vary.

Other signs of a sprung or broken shock spring are bluing or darkening on the top of the shock at the point of contact with the bearing and housing. The bearing and housing will also be flared out from heat and friction. When assembled the motor will be wicked hard to rope over.

-

This reply was modified 5 years, 4 months ago by

aquasonic.

January 5, 2019 at 8:17 am #161958Whether the spring is broken or just sprung, the shock will need to be pressed to exactly 6 11/16″ long. I took a look at the posted pictures, and don’t see anything obviously wrong. Get a good linear measurement and see what you have there.

If the measurement is greater than 6 11/16″ then clean up the inside and inspect it with a high intensity flashlight for a break. If it’s broken, then it must be welded. If it’s not broken, then I have had luck just pressing them back to spec, and putting them back in service. Opinions will vary.

Other signs of a sprung or broken shock spring are bluing or darkening on the top of the shock at the point of contact with the bearing and housing. The bearing and housing will also be flared out from heat and friction. When assembled the motor will be wicked hard to rope over.

I agree.

-

This reply was modified 5 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.