Home › Forum › Ask A Member › Mid fifties pressure tank rebuild problem

- This topic has 11 replies, 5 voices, and was last updated 4 months, 3 weeks ago by

JohnRude.

-

AuthorPosts

-

September 22, 2025 at 4:42 pm #300058

I finally cycled around to checking out my 5.5 and 7.5 OMC motors. I keep one dedicated two line tank for them. Last fall I drained the fuel from the tank. This week I mixed up some new fuel, filter it into the tank, hooked up my 1956 7.5. The carb bowl filled but the motor wouldn’t start. Then I noticed fuel squirting out around the push button for pumping air into the tank. The more I pumped the more it squirted. I took the whole tank apart and replaced the cork, the rubber membrane and cleaned everything including the inside of the tank. I also rebuilt the fuel connection and made up a new fuel line. (Why not?) ?Put it all back together and exactly the same thing happened. I hooked my 1:24 tank. The motor started on the second pull. I ran it a while then quickly switched to my 1:16 tank. The motor ran kind of rough but fuel squirted out around the button pump again.

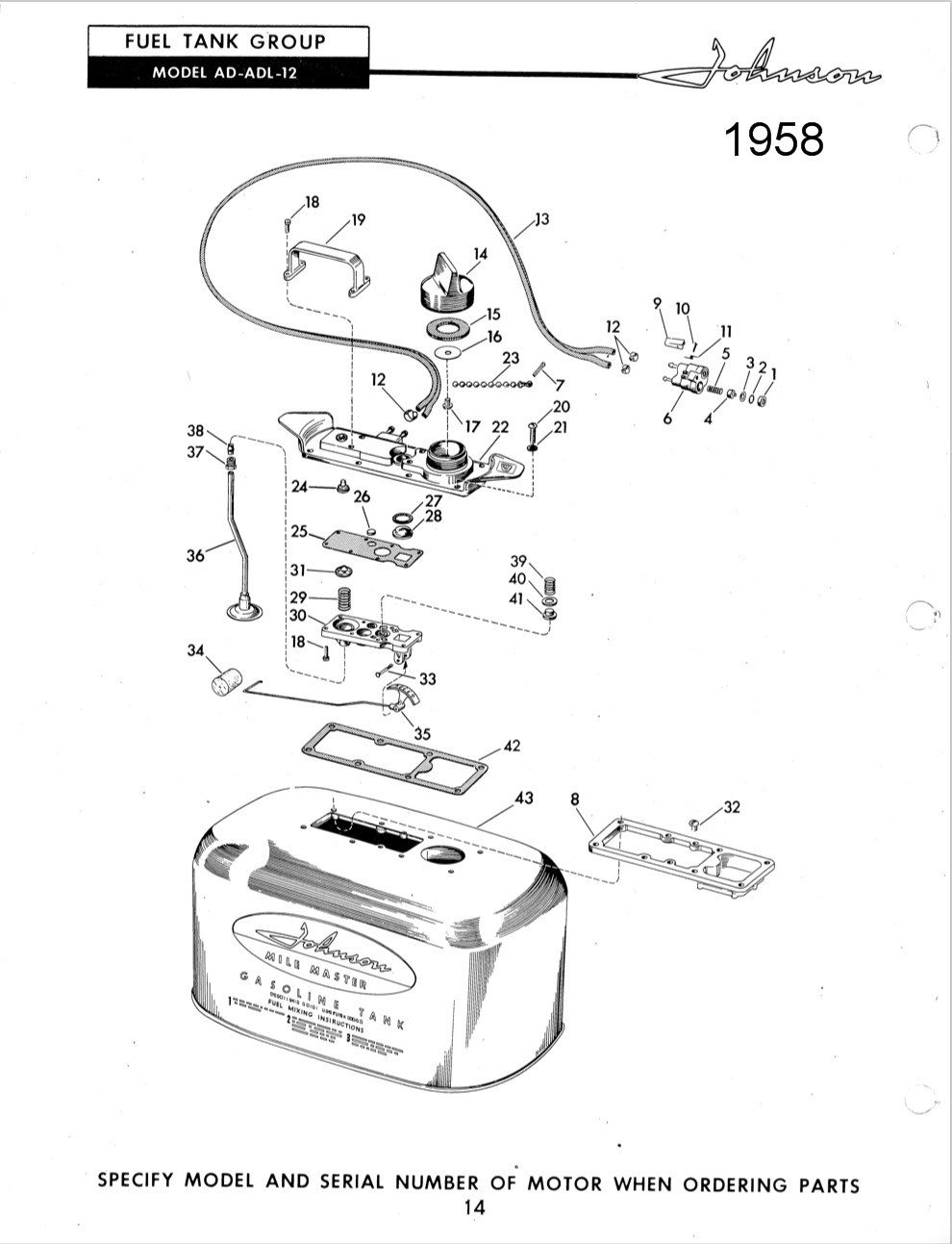

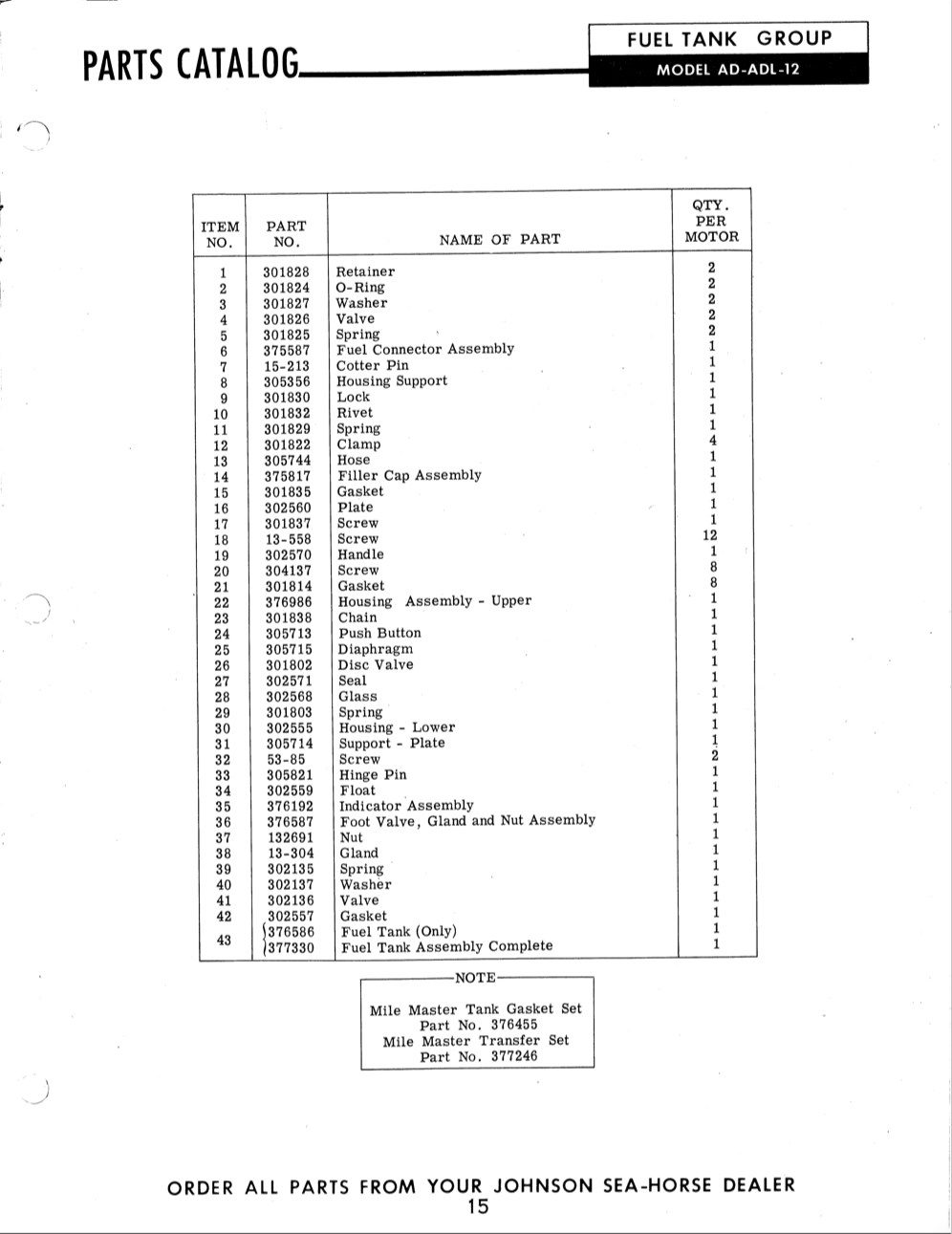

Can anyone suggest what I did wrong? This is the newer style set up with plastic button and I can’t find a decent picture for it. The one in the parts manual isn’t very good. I made sure to check that the connectors were air to air and fuel to fuel. Air is going in and fuel is reaching the motor.

September 22, 2025 at 5:37 pm #300059If it is leaking by the plastic button, my guess would be your rubber gasket moved, or has a hole and should not where the button is….the plastic button gasket should NOT have a hole under the button, if it does you have the wrong gasket..

http://www.richardsoutboardtools.com

classicomctools@gmail.comSeptember 22, 2025 at 8:45 pm #300060September 22, 2025 at 10:19 pm #300063Also JohnRude, just an FYI, pressing the push button does not pump air into the tank. It pumps fuel up one side of the dual hose fuel line to the motor. Once the motor starts, crankcase pressure pushes air through the other side of the dual hose, originating at the manifold nipple, into the tank. The pressure accumulating in the tank then pushes fuel back up through the fuel line to the motor, and so on.

September 22, 2025 at 10:35 pm #300064Thanks guys. Yes, I used 305715. I do have both. One thing though, it was my last one and it didn’t feel right. Too stiff. The one that I replaced was soft and pliable and old. I got to wondering if I didn’t put the metal parts in correctly. Wish I had a parts diagram for the newer version. I restored several tanks this past winter and none were tested. So I got the one out that was destined for my mint 56. I’ll attach a photo. The tank and motor worked perfectly. I’m not crazy. Yahoo.

September 23, 2025 at 5:24 am #300067Here’s a parts diagram for the newer style and other info you might find useful. Up to 1956 the tanks had an aluminum push button and push rod. In ’57 they went to a black button with two riveted disks on the diaphragm. In ’58 the mushroom shaped button with a single disk for the return spring.

There is a kit 377327 that can be used to upgrade ’57 to ’58 style.

September 23, 2025 at 8:08 am #300072Very interesting, thanks! So you are saying there is an updated set up for the newer plastic button set up?

September 23, 2025 at 10:17 am #300078September 23, 2025 at 10:54 am #300082Interesting. I never realised that was how it worked. I did know that the crankcase is pushing air back to the tank.

Now that I think of it the push button is over the fuel intake pipe that pulls from the bottom of the tank. Thanks. So it’s the pressure coming back from the crankcase that is blowing past something to force fuel out around the button. It’s a mechanical problem not a membrane problem. As Crosbyman says, “it pays to be a member”.

September 23, 2025 at 11:29 am #300083It’s not the pressure coming back from the crankcase that’s your problem. Something isn’t seated properly, or installed correctly, or there is a pin hole leak somewhere that is causing fuel to squirt out when you push the button. Time to open up that handle assembly and double-check everything.

-

AuthorPosts

- You must be logged in to reply to this topic.