Home › Forum › Ask A Member › misc oil seal puller

- This topic has 16 replies, 7 voices, and was last updated 5 years, 2 months ago by

crosbyman.

-

AuthorPosts

-

February 17, 2019 at 10:19 am #167172

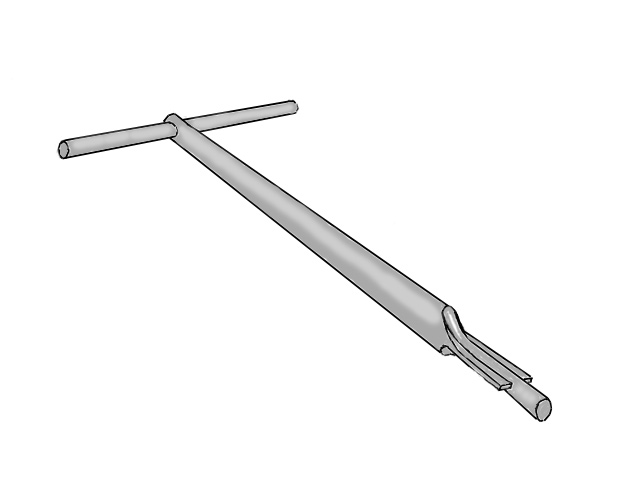

are these any good to pull out prop shaft oil seals ( bearings yes since it is a bearing puller )

my 5.5 prop shaft oil seal is a bit of a pain to pull out so I may as well invest in something better than a pick and shovel to do the job

the oil seal lip itself is a bit narrow…. will the oil seal edge just crumble as I try to pull it out with this tool

any suggestions ….

Joining AOMCI has priviledges 🙂

-

This topic was modified 5 years, 2 months ago by

crosbyman.

February 18, 2019 at 1:57 pm #167530update:

well a 2 cents flat head 4 inch nail did it.

Simply slide the flat head of the nail under the oil seal inside rim and wack the seal rim while going around the seal

Hold the seal & sleeve carrier upside down firmly in a vise with wooded jaws to prevent damage to the carrier

While working in a circular fashion , gently hammer the nail pointy end now made flat by grinding it off first and

work in a circular fashion to push the seal out evenly

Joining AOMCI has priviledges 🙂

-

This reply was modified 5 years, 2 months ago by

crosbyman.

February 18, 2019 at 2:50 pm #167538There is an actual puller for the lower units of that vintage. I have one as I bought it from Frank Robb a few years back.

I had intended to duplicate it but the cost for that would be up there as there are 3 different heads and all the other stuff.

I have thought of modifying the seal pullers I currently make to function and pull those seals, but it takes time to develop them.

They are still on my list.

Do you need the part number of that tool?

Richardhttp://www.richardsoutboardtools.com

classicomctools@gmail.com-

This reply was modified 5 years, 2 months ago by

RICHARD A. WHITE.

RICHARD A. WHITE.

-

This reply was modified 5 years, 2 months ago by

RICHARD A. WHITE.

RICHARD A. WHITE.

February 18, 2019 at 3:25 pm #167543send me pm and cost but a 4 inch nail at 2 cents is darn cheap for my needs 🙂

Joining AOMCI has priviledges 🙂

February 18, 2019 at 3:35 pm #167545I would be interested in that tool , as pulling the prop shaft and driveshaft seals are very annoying. The shift rod seal is a breeze!! Thanks.

February 18, 2019 at 4:21 pm #167548The outrageously expensive factory seal puller slipped over the prop shaft so all you had to do was remove the propeller. It also included a sort of funnel that covered the shear pin hole so the new seal would not be damaged by any sharp edges. . .

The slide hammer also has many uses . . .

-

This reply was modified 5 years, 2 months ago by

garry-in-michigan. Reason: Correct spelling errors

garry-in-michigan. Reason: Correct spelling errors

February 18, 2019 at 6:13 pm #167552That puller is a picture of one of Frank’s correct, and for a crank shaft seal?? And I cant seem to find the OEM # for my tool…

http://www.richardsoutboardtools.com

classicomctools@gmail.comFebruary 18, 2019 at 9:22 pm #167571I have tapped up the area with masking tape, then drill a very small set of holes 180 degrees apart. Next screw in a drywall screw on either side & pry out using a block of wood as the fulcrum. A little heat helps soften the adhesive the factory uses.

February 19, 2019 at 3:14 pm #167632update:

well a 2 cents flat head 4 inch nail did it.

Simply slide the flat head of the nail under the oil seal inside rim and wack the seal rim while going around the seal

Hold the seal & sleeve carrier upside down firmly in a vise with wooded jaws to prevent damage to the carrier

While working in a circular fashion , gently hammer the nail pointy end now made flat by grinding it off first and

work in a circular fashion to push the seal out evenly

Am intrigued by your simple method but am having a hard time understanding just what you did with the nail….That seal remover kit looks nice, certainly reasonably priced, but those darn gearcase seals are a royal pain, and that puller would probably just bend the metal seal housing lip up and pop out. The aluminum housings are very delicate and easy to damage/break.

Please explain your nail method one more time, sounds simple and effective….DonFebruary 19, 2019 at 10:42 pm #167657Basically …having no puller I still needed to remove that seal.

the external flange (seal rim) facing the prop is very thin and tears away if you try to pull it with pliers

Normally on a trailer bearing hub you reach in from behind the removed hub, line up a flat screw driver in the bearing inner edge and by alternately hitting the bearing rim from behind it gets pushed out.

I coud not use a flat screwdriver on the seal because the diam. is only .554 making the strike angle to narrow to reach the outer edge on the seal .

by using a 4 inch galvanized nail the angle of attack is the same but the nail’s flat head can contact the full “back rim” of the seal . there is enough room behind the seal to sneak in the round flat head between the seal surface and the carrier body .

hitting the nail from the other end (pointy end ground flat) allowed me to push out the seal by wacking it a few times at 90 degree spacing

If that seal would have been seated all the way in against the carrier I would not have been able to fit in a flat head nail

I can’t say if that seal is or is not normally pushed …all the way in… maybe the PO did not push it in all the way that is why I could sneak in the flat head behind it.

Joining AOMCI has priviledges 🙂

-

This topic was modified 5 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.